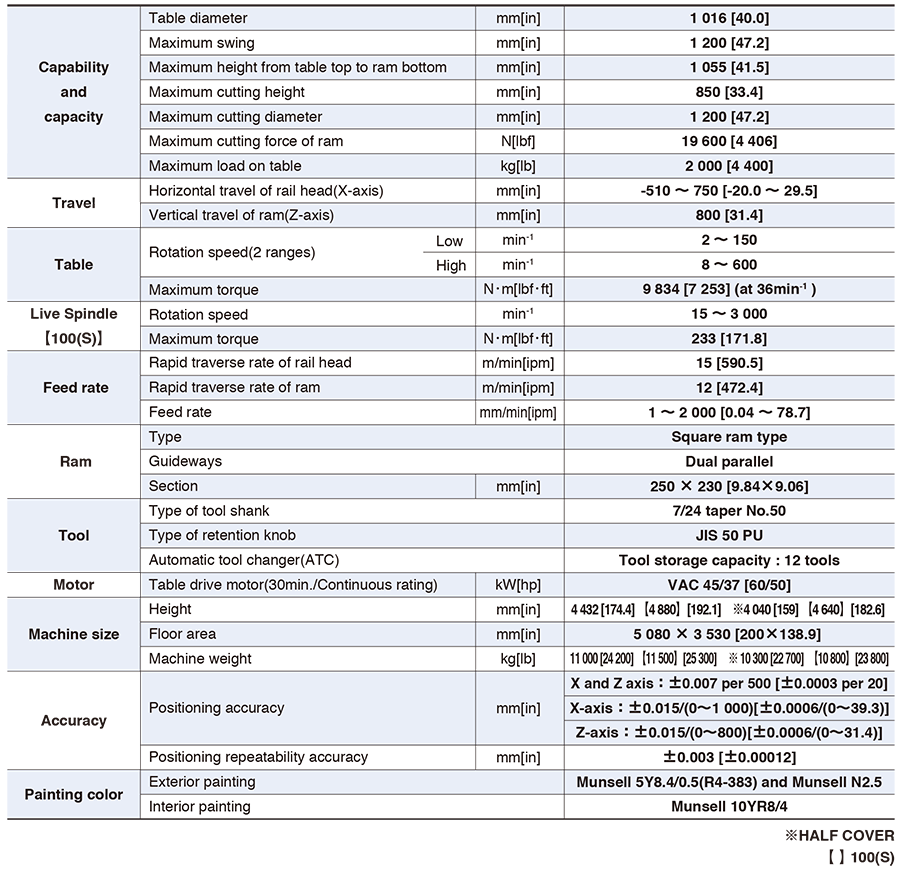

Ram size is the same as larger model.

The column and arm which support the rail head is designed in a single piece of wall type column with higher rigidity to be able to work under heavy duty.

Fast rapid traverse reduce manufacturing time.

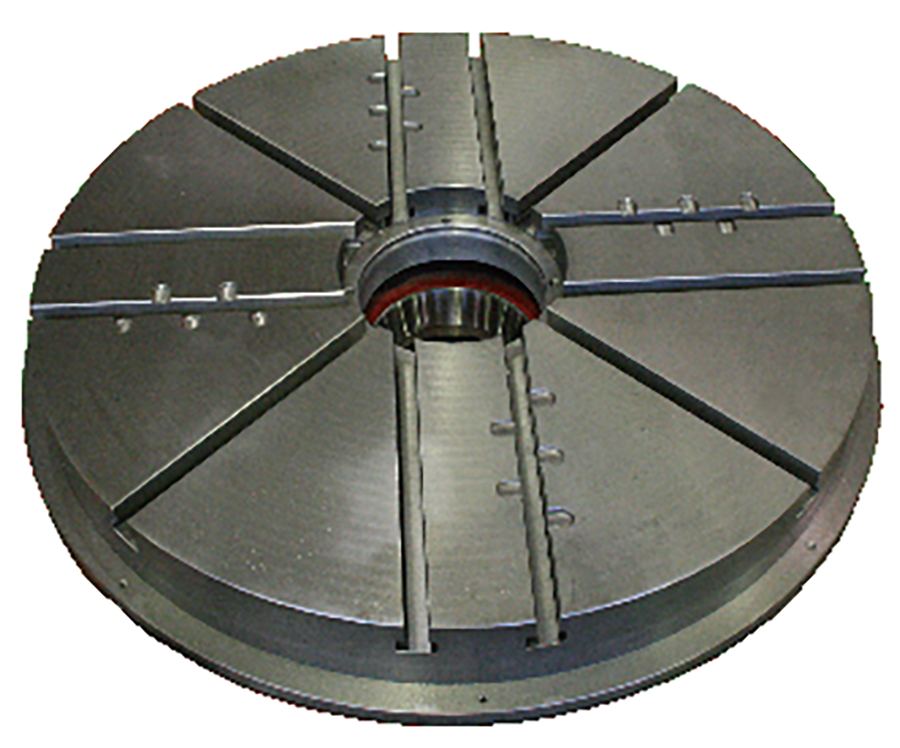

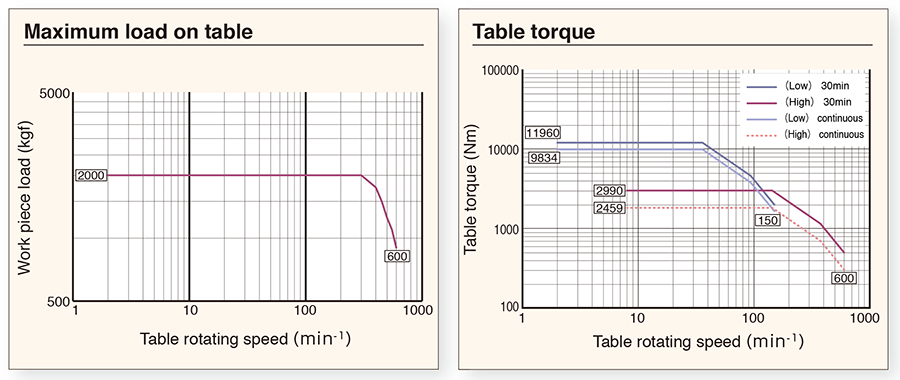

The table run in wide speed range and make it suitable to work on workpiece made of various kind of material .

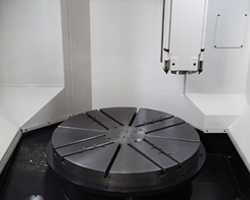

Fully closed cover around the table is standard specification to avoid coolant and chips splash around and alleviate noise from machining.

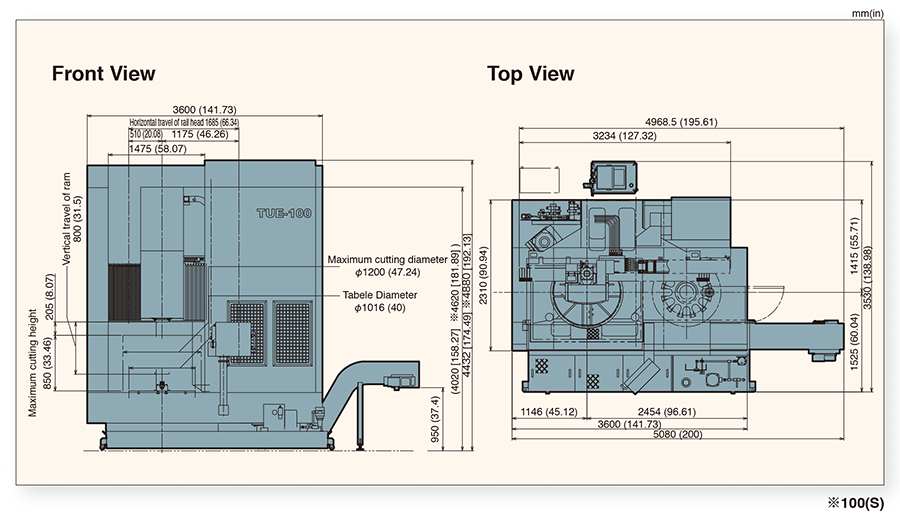

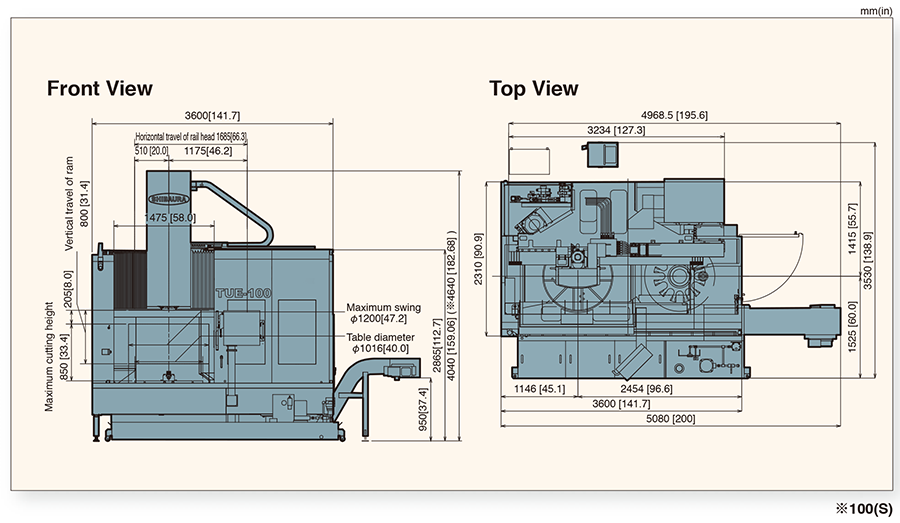

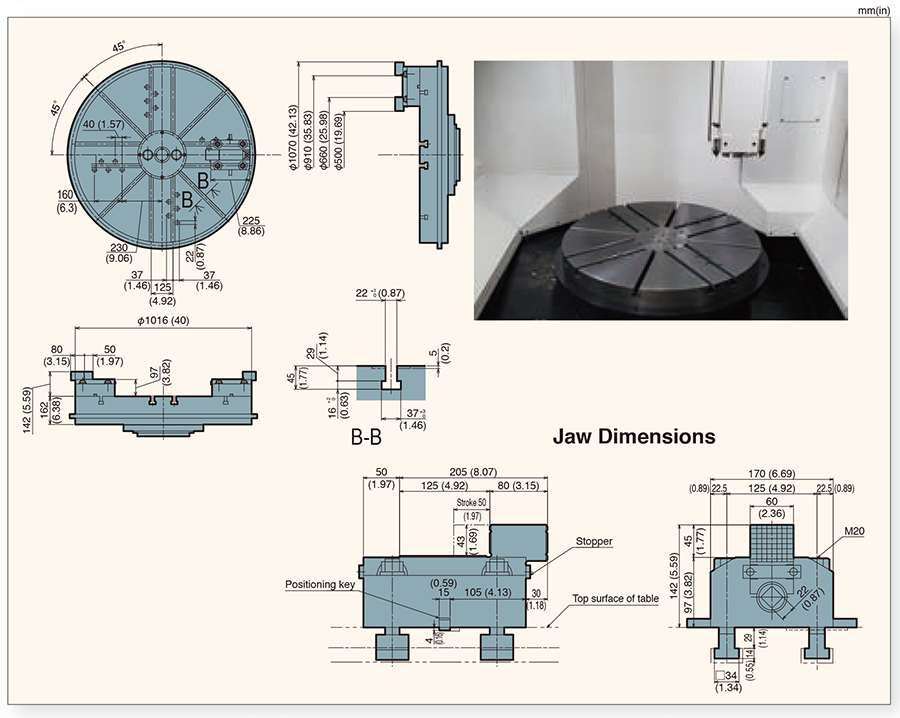

●Table diameter:Φ1016㎜ (Φ40in)

●Maximum swing:Φ1200㎜ (Φ47.2in)

●Maximum cutting height:850㎜(33.5in)

[Maximum height:1055㎜(41.5in)]

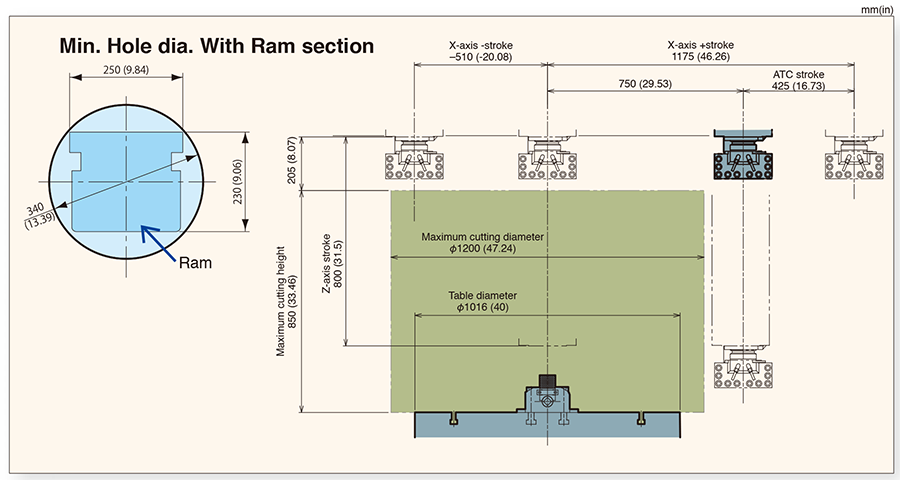

●Travel (X-axis×Z-axis):

(X-axis)-510~750㎜(-20.0in ~ 29.5in) (Z-axis)800㎜(31.4in)

●Table drive motor :AC45/37kW (60/50HP)

●Table speed:2~600min-1

●Floor space:5080×3530mm (200×139in)

●Machine height:4432mm (174.5in)

●Mass of machine(including CNC system): 11 000kg (24 200lbs)

Main structure is made up using a thick high-quality cast iron.

The wall-type column with a large cross-sectional shape and the cross rail are a single casting designed to reach out to the table center. This type construction firmly supports the rail-head for high-precision, high speed positioning, and heavy cutting.

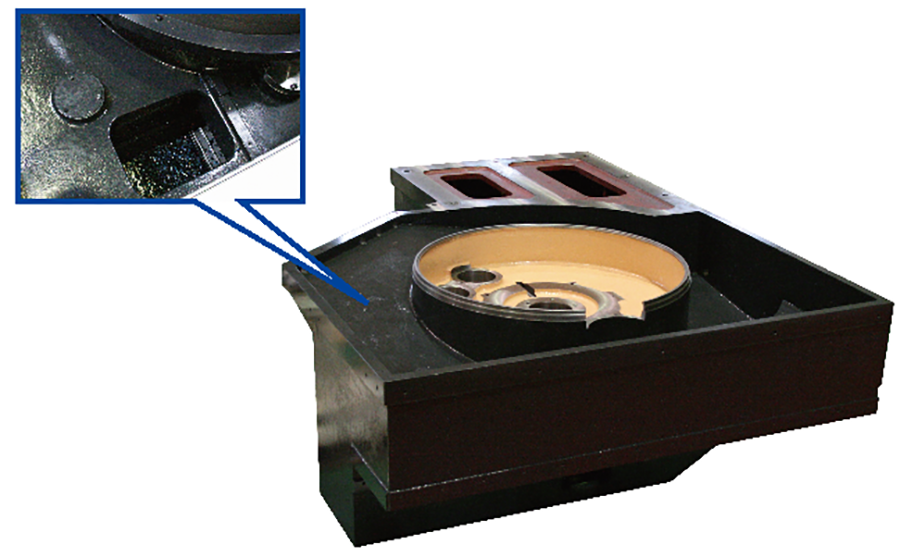

The bed, made of cast iron, was engineered for maximum support of the Table and Column. By design, the chips efficiently flow down the slope shape of the bed into the standard chip conveyor with the aid of a shower type coolant.

The table is supported by a combination of 2 different types of bearings, a tapered roller bearing which bears the radial load and a large diameter thrust ball bearing which bears the axial load. This combination makes high-speed and heavy cutting possible.

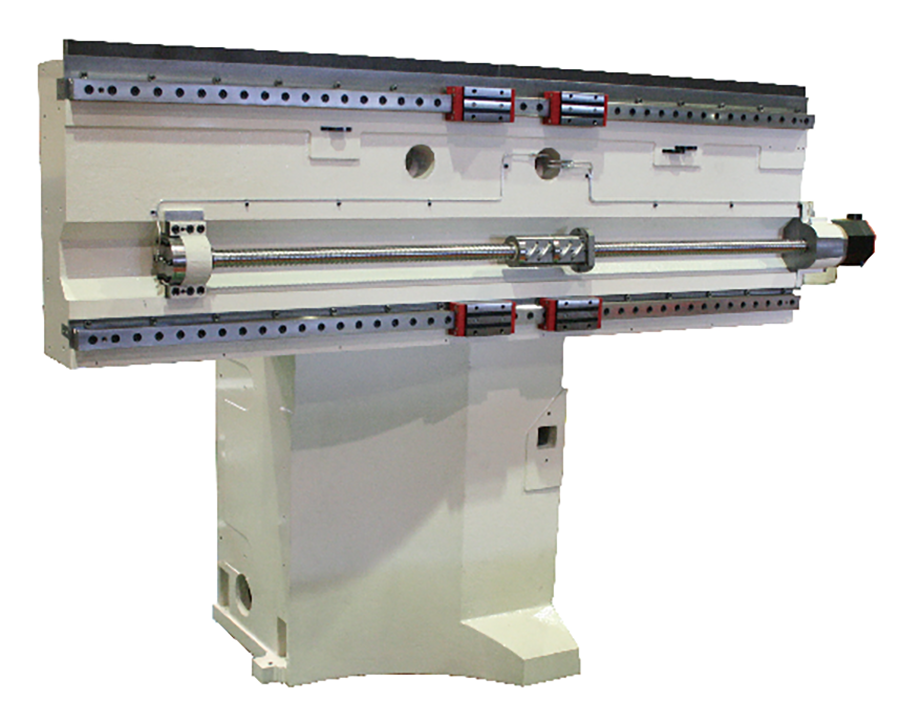

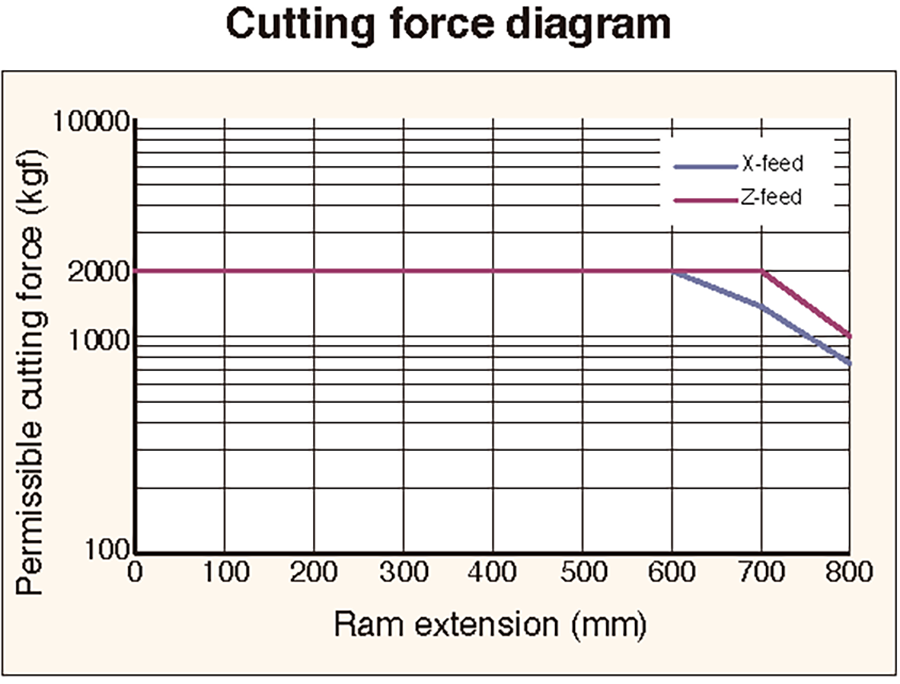

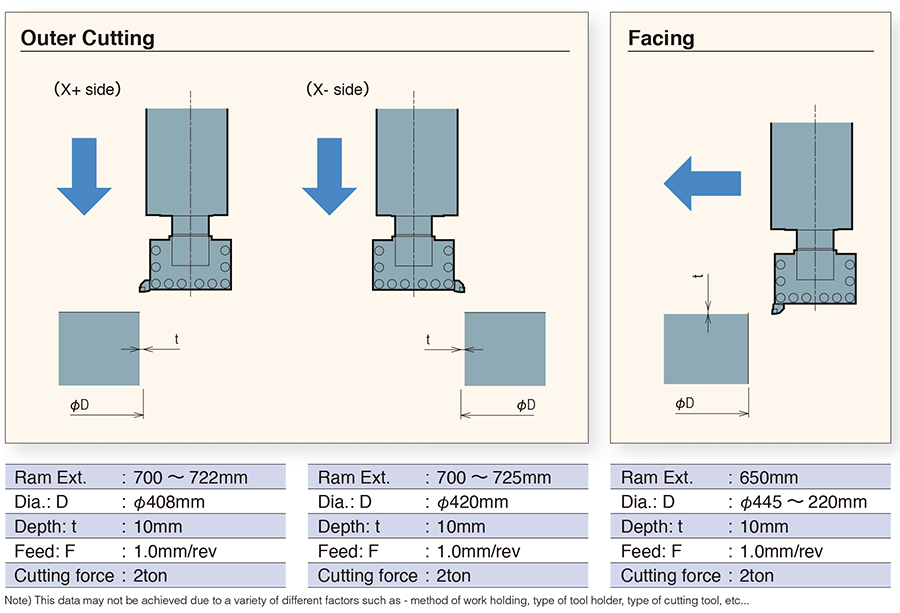

The Railhead and Ram create a hybrid system of motion utilizing large diameter ball screws with linear roller guide ways for the X axis and Hardened and Ground box slide ways for the Z axis making it possible for high-precision and high speed positioning to coexist with heavy cutting.

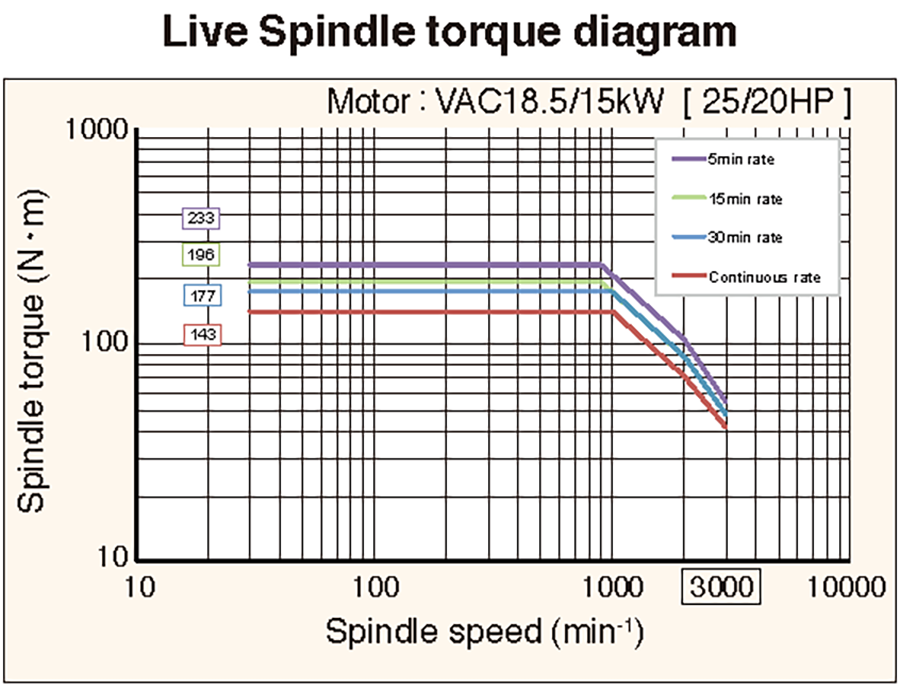

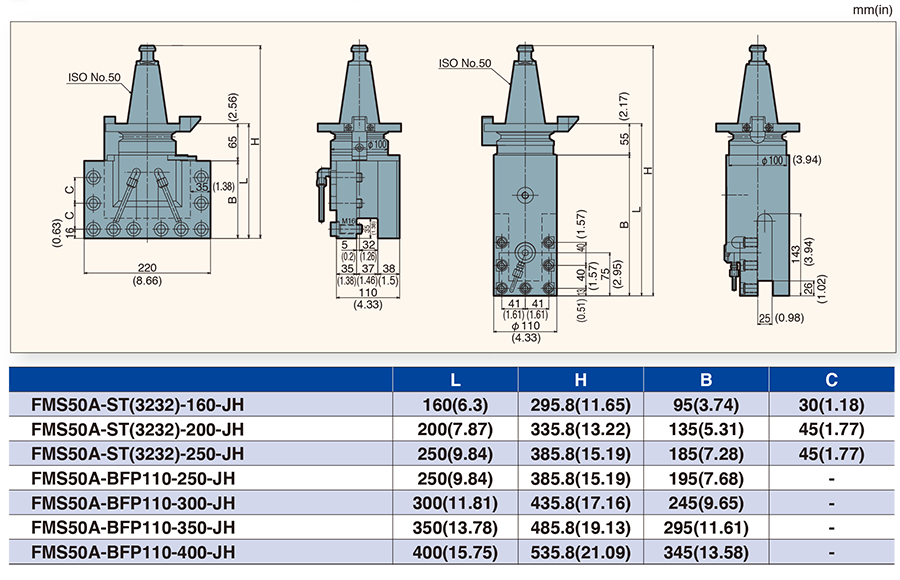

Tool can be clamped/unclamped automatically in the Spindle (ISO taper No.50) with the collet type pull stud and the spindle is driven by the AC type motor located at the top of the ram.

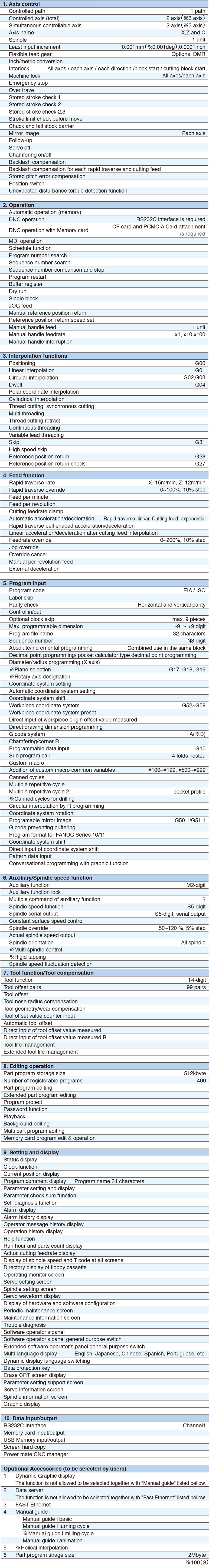

Most advanced CNC controller of FANUC series 0i-TF is applid on the machine.

Most of functions including optional functions in Fanuc’s classification are specified as standard. In addition to common operational functions, the machine is provided with such oprator friendly functions as help function, alarm display, and display of operation status to assist operator.

The “TUE series machine can be operated in manual very easily, in addition to automatic operation. Many opration buttons to be used in manual mode are located on the operation panel, which are “Table CW/CCW” including jogging, Feed selection switch for X and Z including jogging, “Table speed overrideswitch”, “Feed override switch” “Operation mode selection buttons”, and Manual pulse generator (MPG)”.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.