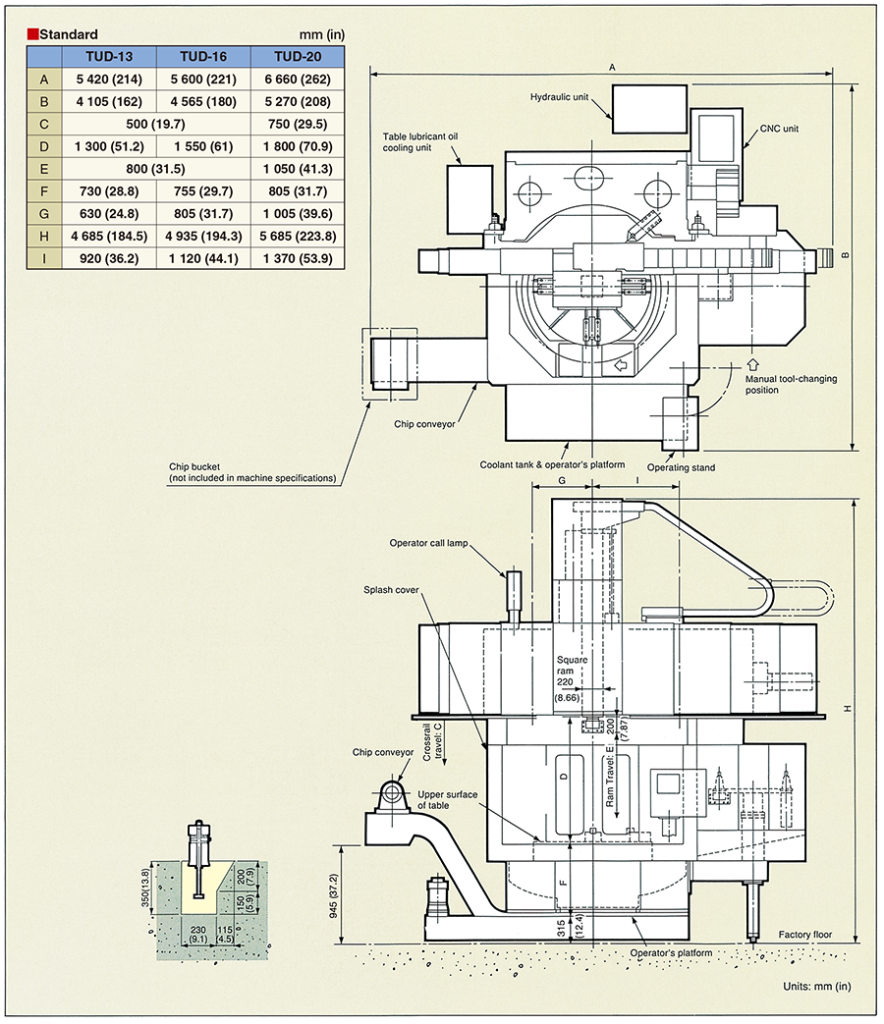

The thick-walled, cast Iron column and be is thermal symmetrically designed for high precision and heavy-duty machining

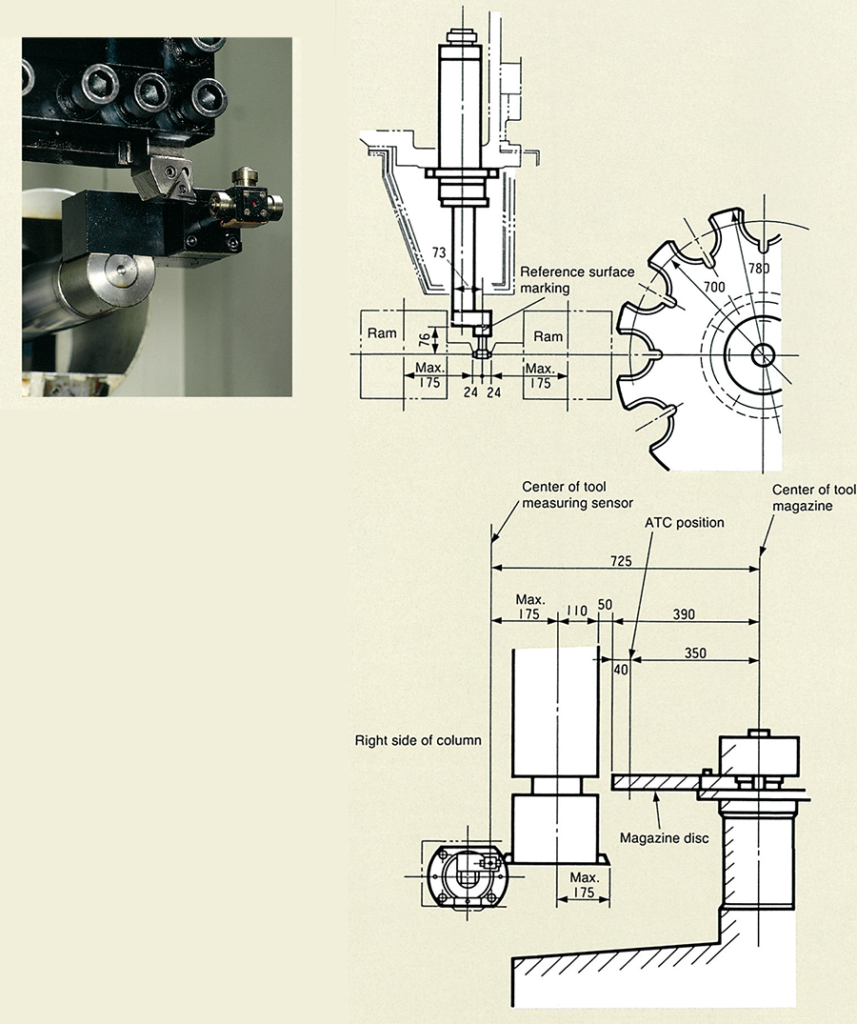

The 220mm (8.66 in) square ram is solidly encased in a mono box structure which is incorporated with an automatic tool-locking mechanism

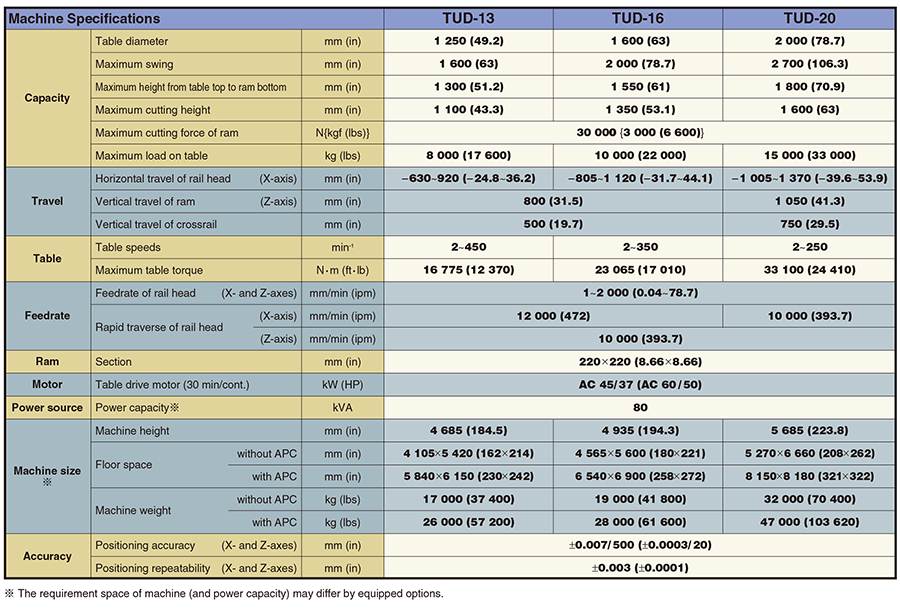

A step positioning mechanism moves the crossrail a maximum 0f 500mm (19.6in) vertically in 250mm (9.84in) steps [750mm (29.5in) for TUD-20] for virtually all workpiece heights

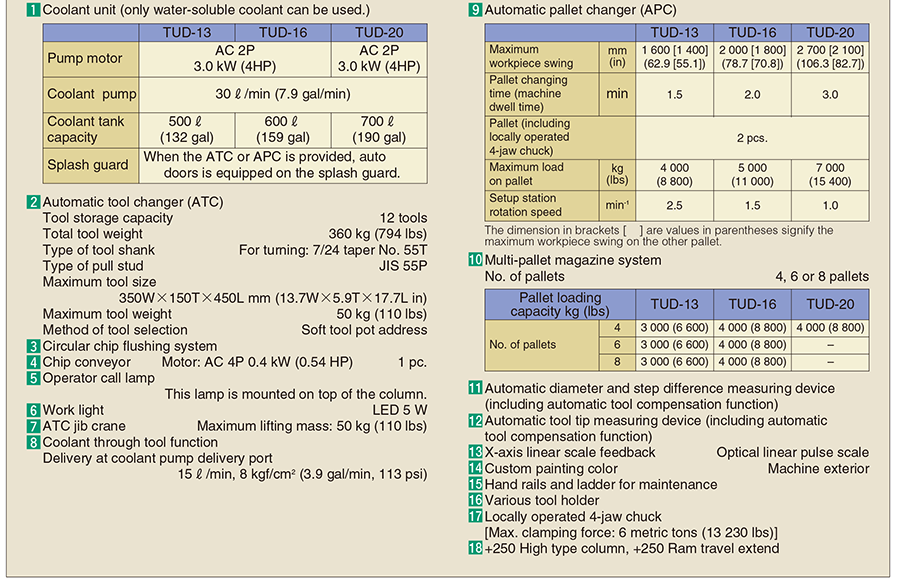

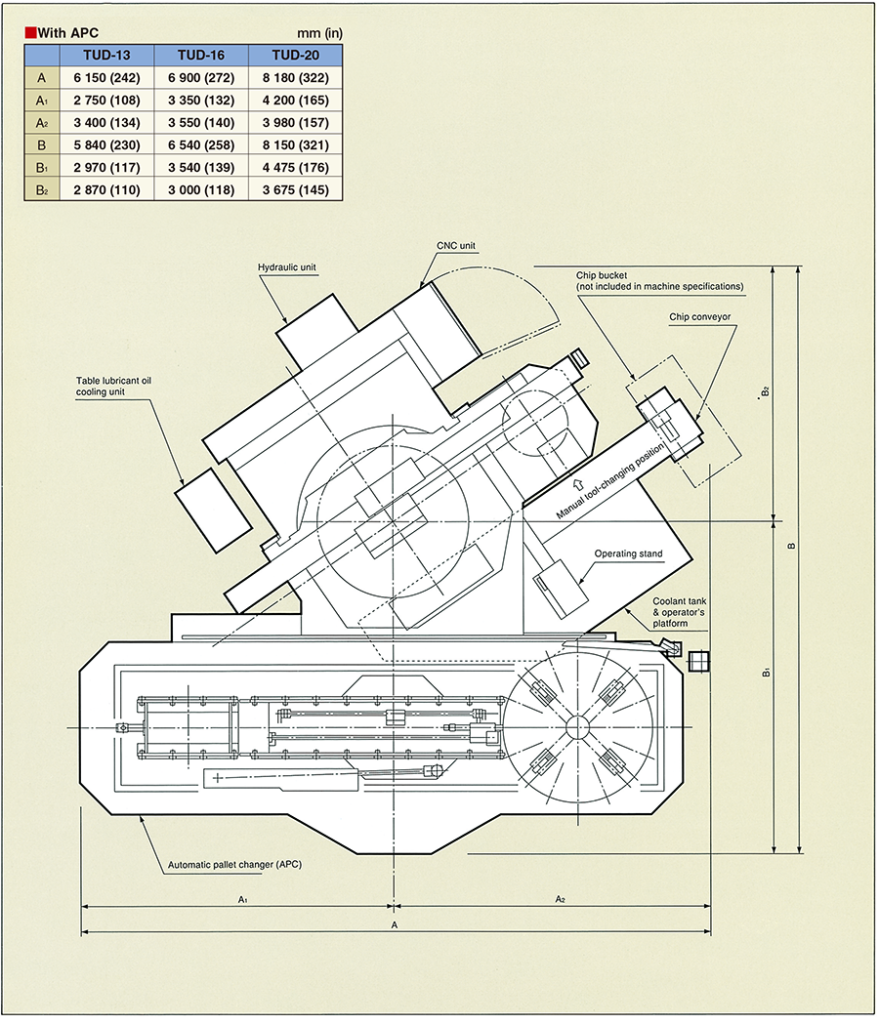

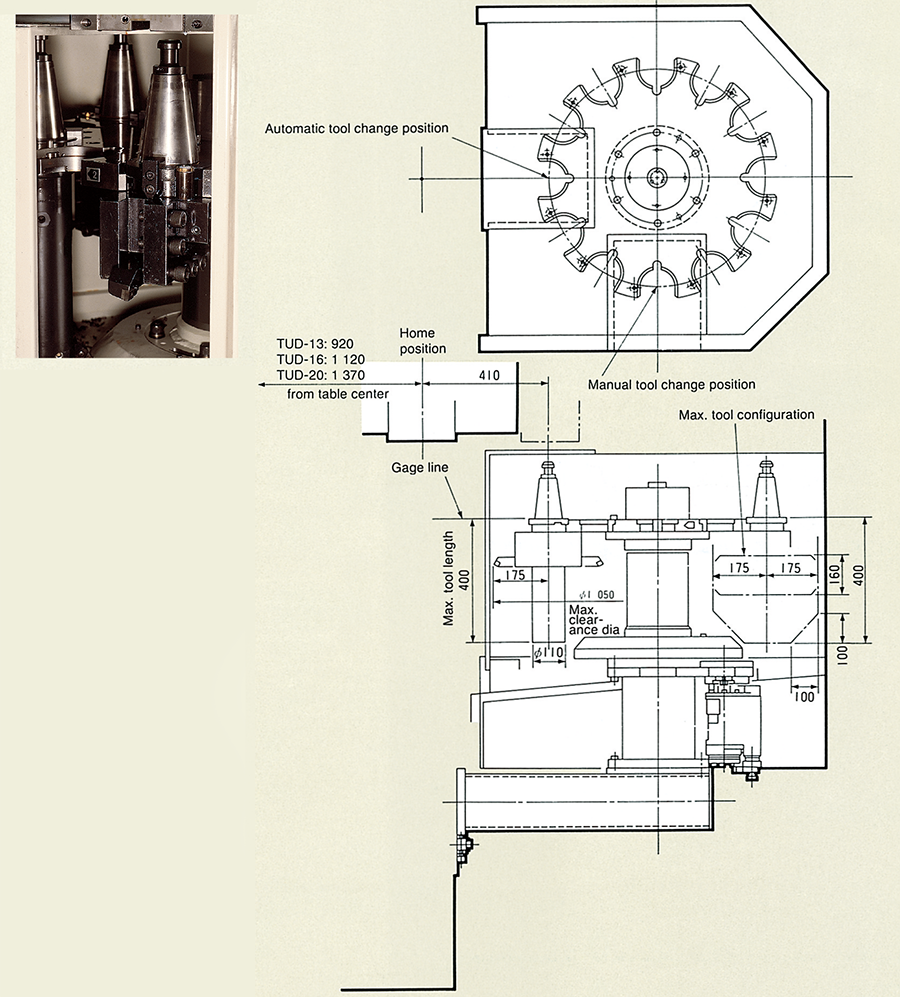

Special options, such as an automatic tool changer (ATC) and an automatic pallet changer (APC) are available for even greater degrees of automation and labor saving

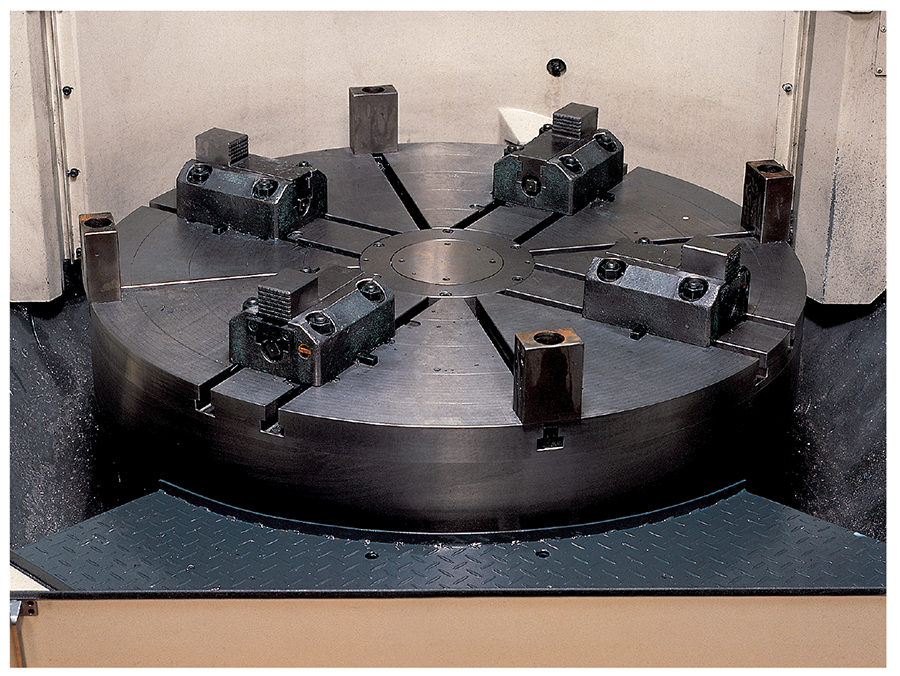

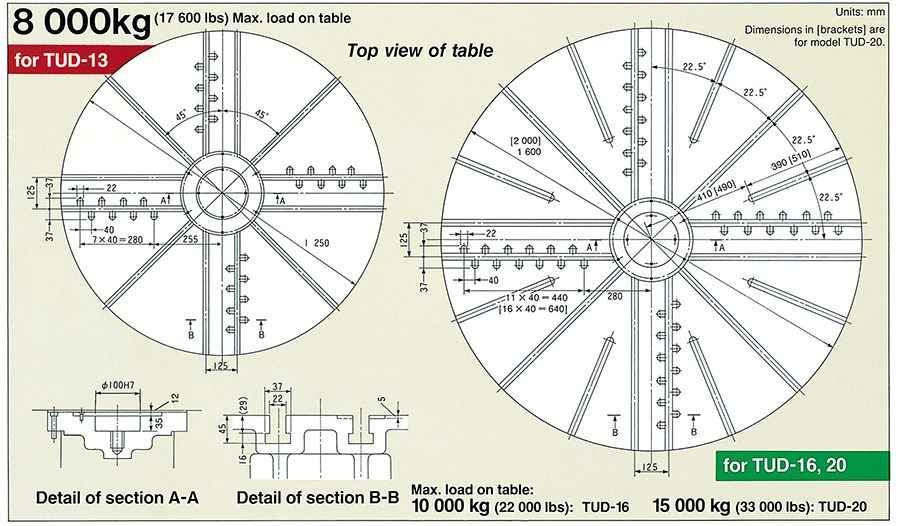

All of the major machine components are constructed of high-grade castings. The table has been provided with ample strength and size and is supported on a largediameter thrust ball bearing and tapered roller bearing arrangement. This type of arrangement assures adequate support fo extremely efficient, high speed heavy machining. In addition, the talbe is equipped with 4 independent manually-operated jaws and T-slots that guide and hold the workpiece in the required position.

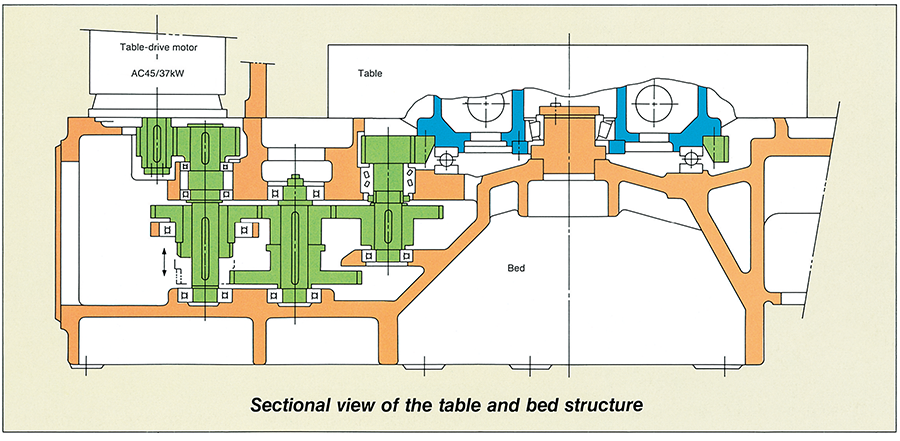

Thermal deformation is minimized by the standard-type lubricating-oil cooling system and the thermally symmetric layout of the machine bed which supports the table. Additionally, the table-drive mechanism is built into the rear section of the bed, and column is standing on the bed.

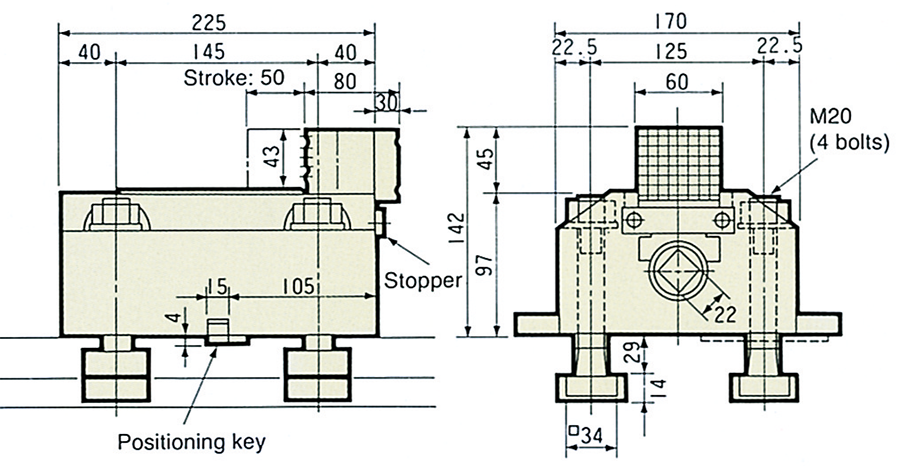

Four jaws with the following specifications are supplied as standard accessories.

The table is driven by a 2-step gear speed-change motor with a large-diameter helical gear located beneath the table. Speed changes are carried out by the 2-stage hydraulic shifting in combination with the variable speed AC motor. Excellent rigidity and minimum heat generation is assured by the simplified and thermally symmetric arrangement of the gear-train.

The column is a highly rigid symmetrical box-shaped structure that is provided with 2 slideways. The linear-guide on the crossrail is protected from chips and coolant by steel covers. The vertical travel of the crossrail is performed by a hydraulic cylinder in 250 mm (9.84 in) steps for precise positioning of up to a maximum of 500 mm (19.6 in) [750 mm (29.5 in) for TUD-20].

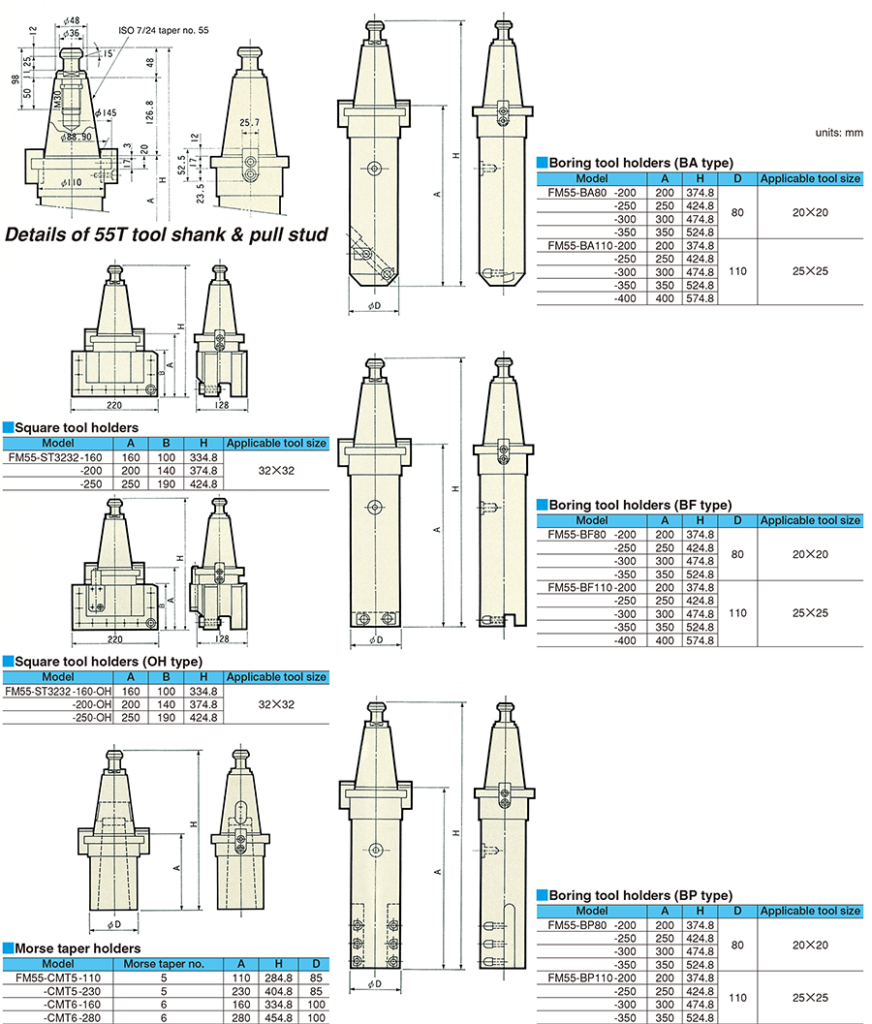

The 220 mm (8.66 in) square ram is securely supported on all 4 sides within a onepiece structure. Large-diameter ballscrews are employed for positioning in the horizontal (X-axis) and vertical (Z-axis) directions. Quick and precise positioning is possible by the special angular ball bearings supporting the ball-screws and the rolling linear guides for the X-axis slideway. The ISO No. 55 taper 7/24 and a collet-type pull-stud mechanism enables the clamping of tools on the ram automatically. Heavy duty cutting capability is assured by the powerful 6-metric ton clamping force.

Machining example | ||

|---|---|---|

Cutting direction | Cutting direction | |

Ram extension | 355 mm (14″) | |

Machining diameter | 670 mm (26.4″) | |

Table speed | Constant surface speed | |

Surface speed | 100 m/min. (328 sfm) | |

Depth of cut | 10 mm (0.4″) | |

Feedrate | 1.3 mm/rev. (0.05″/rev.) | |

Material | S48C (carbon steel) | |

Estimated cutting force on ram | 2 600 kgf (5720 lbs) | |

Note 1: M06, M55, M60, M80, M81 and M83, M84 are the M codes calling a custom macro.

Note 2: M56 and M57 are commanded during tool nose measurement (i.e., M06 or M55 mode). M63~M67 are commanded during tool change (M06) and need not be specified by the customer.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.