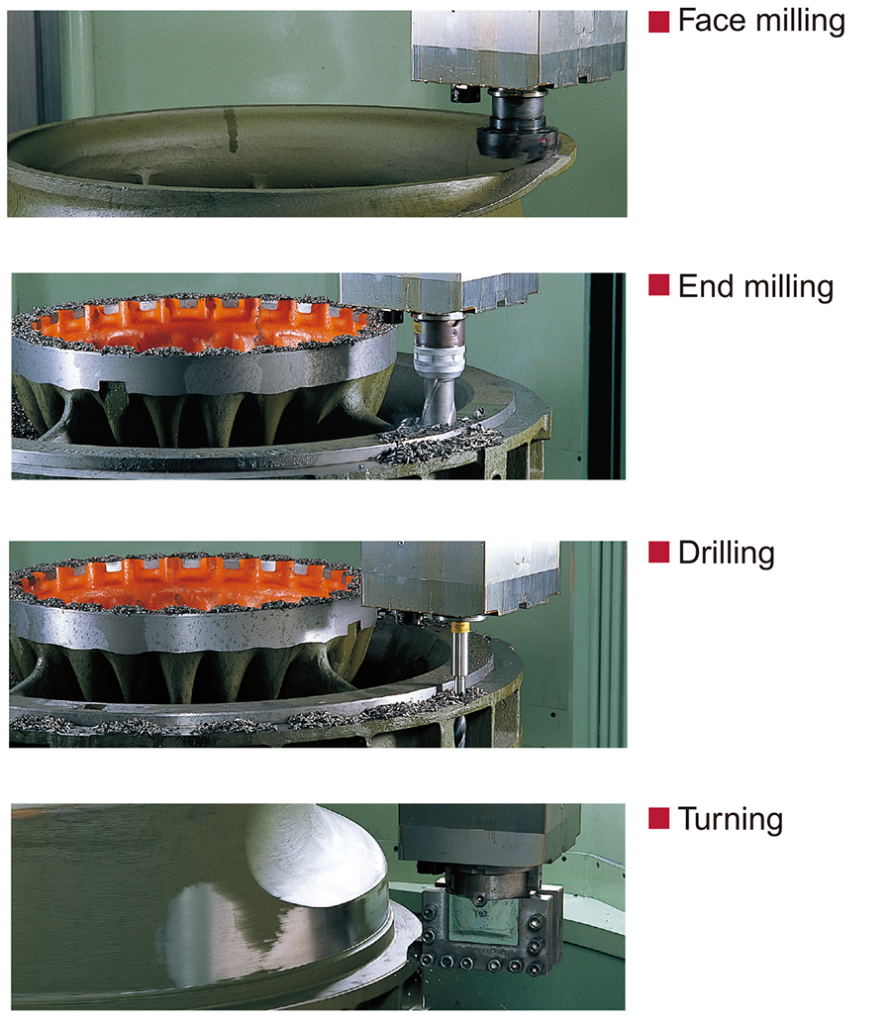

Based on our TUD series general-purpose vertical turning mills, the TMD series also incorporates milling and table index functions such as milling, boring, drilling and tapping can be all accomplished in only one workpiece setup.

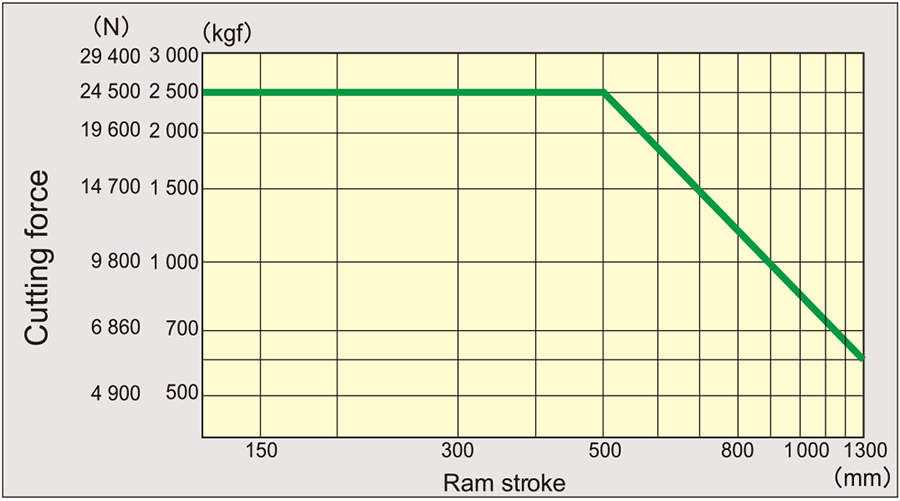

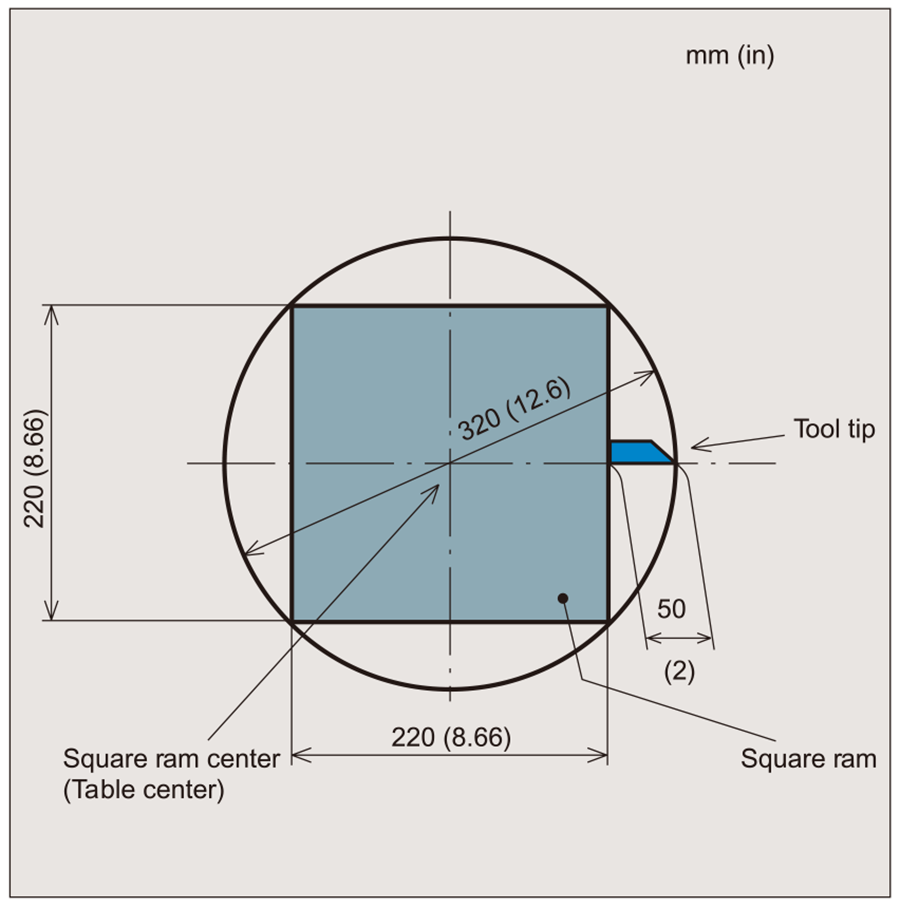

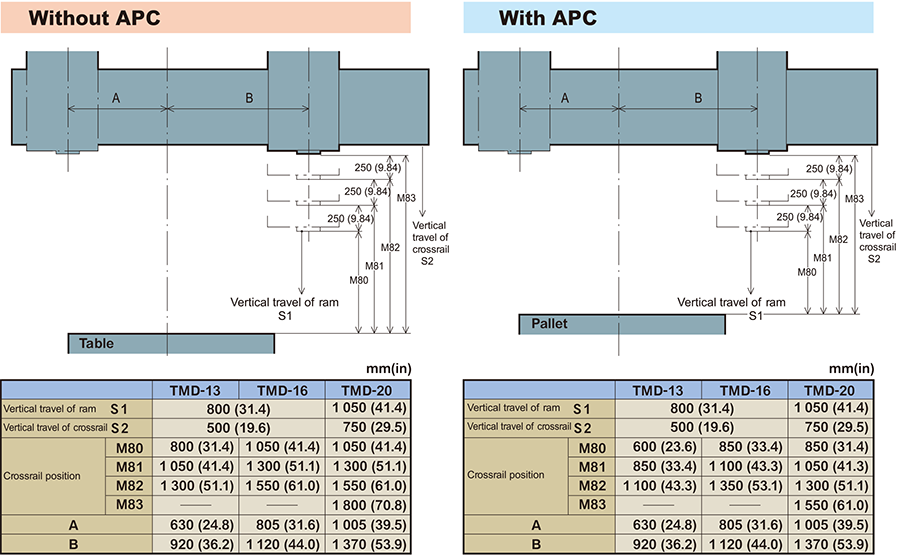

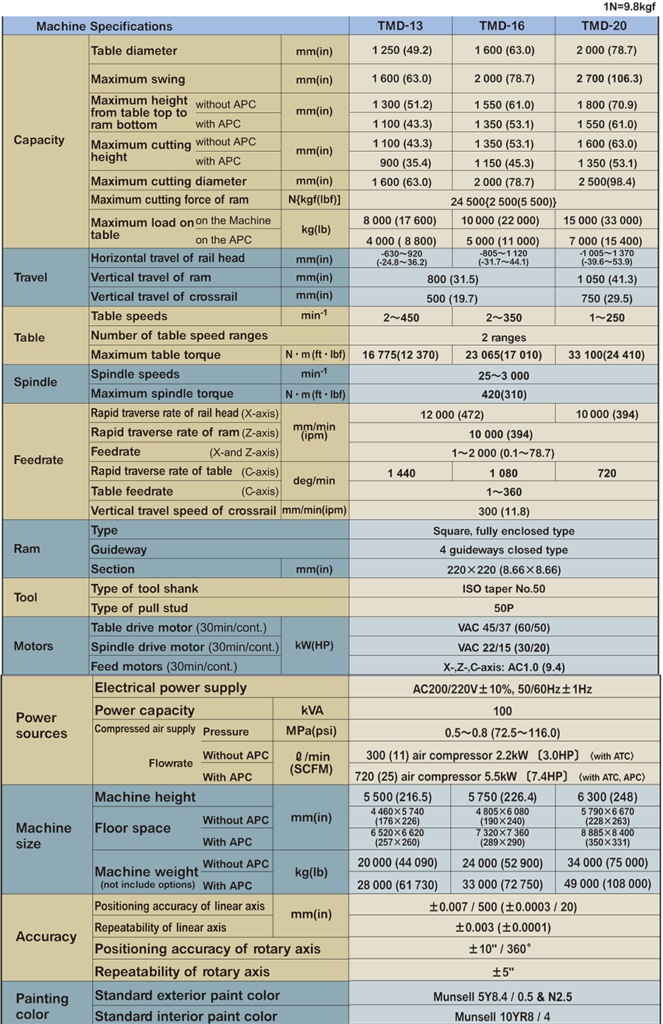

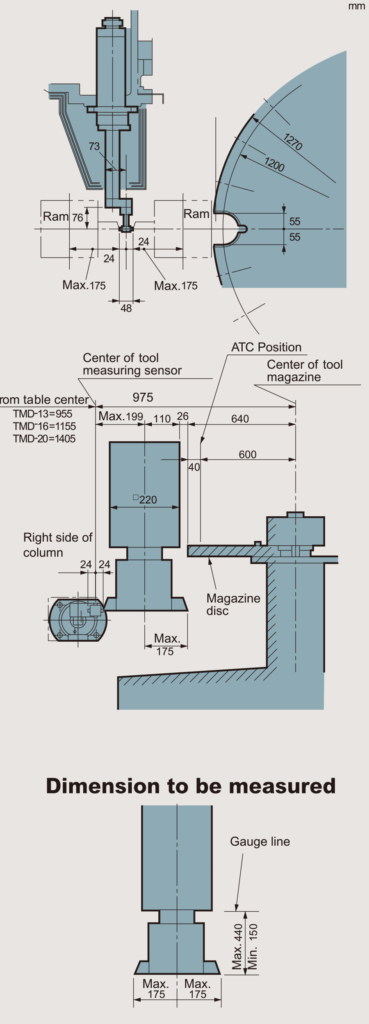

A step positioning mechanism moves the crossrail a maximum of 500mm (19.6in) vertically in 250mm (9.84in) steps [750mm (29.5in) for TMD-20] for virtually all workpiece heights The closed type single-block construction rail head enclose a 220x220mm (8.66×8.66in) square ram. Maximum cutting force of ram: 2500 kgf (5500 lbf). Linear machining by the simultaneous control of X and C axes. (Polar interpolation)

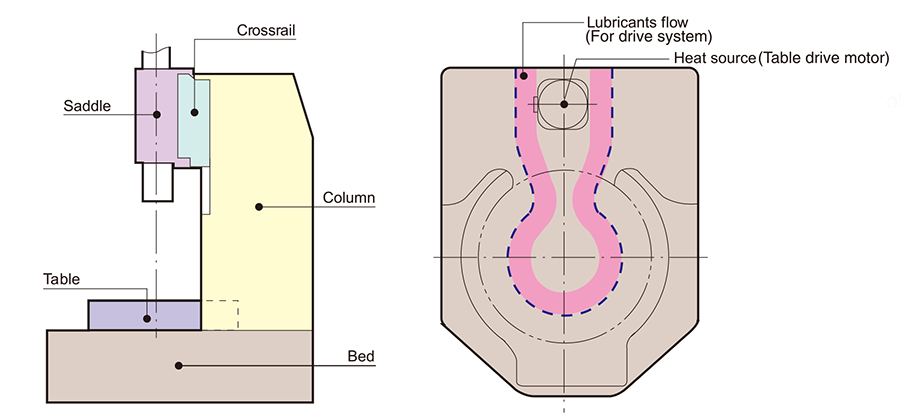

Extremely rigid linear roller guides employed on the X axis slideway Sharply reduced thermal displacement due to symmetrically positioned placement of the motor and symmetrical design of both the table and column

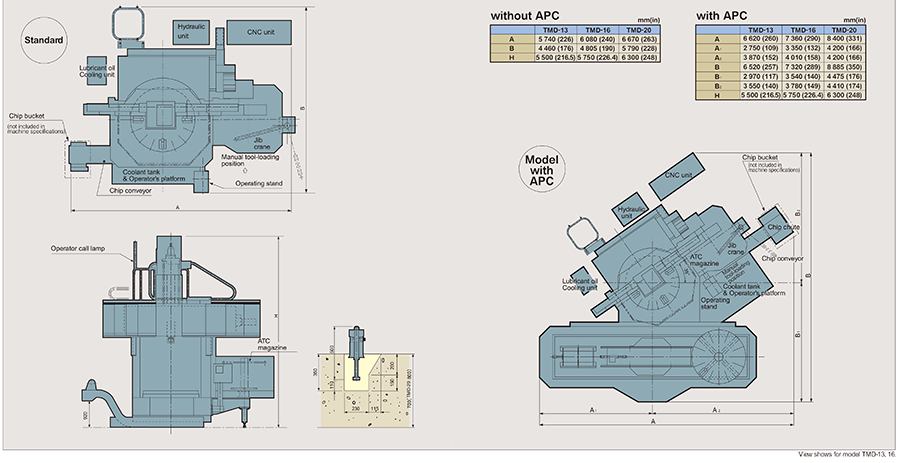

An easily accessible operation panel with centralized controls for all operation functions

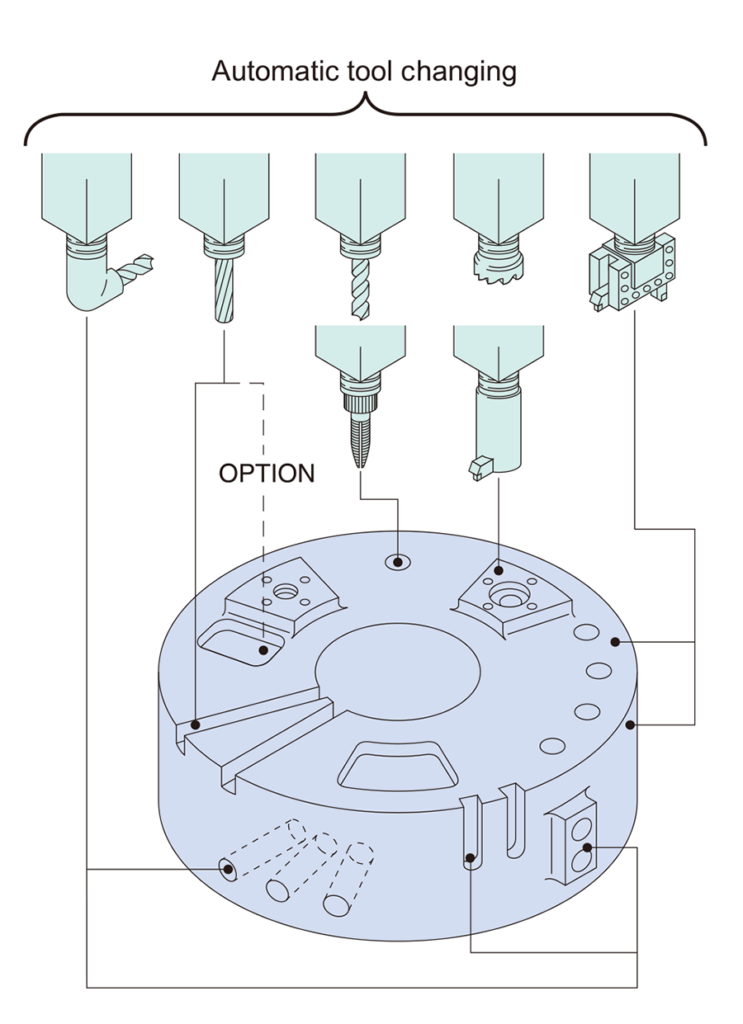

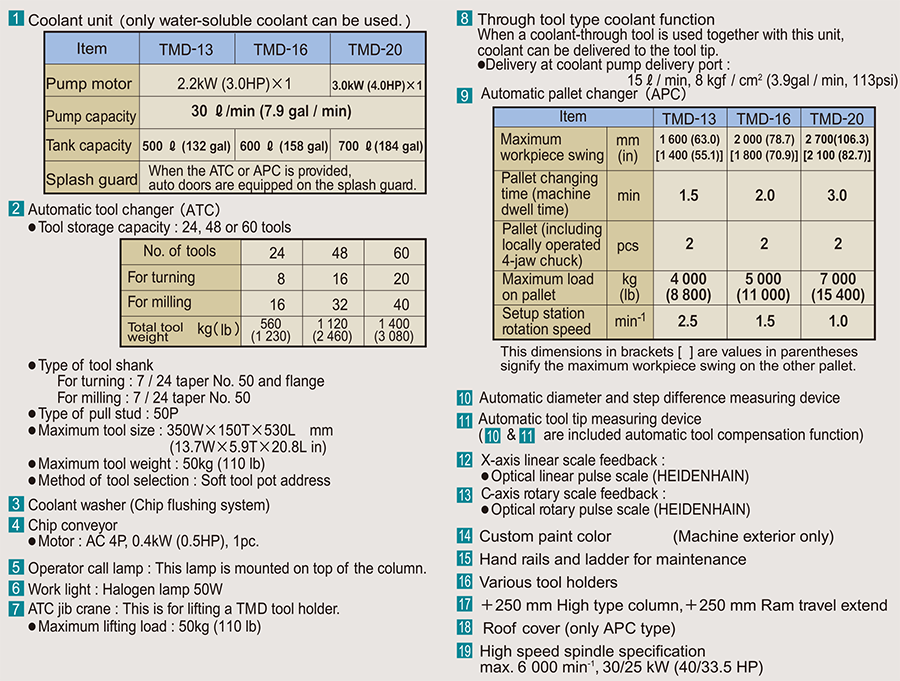

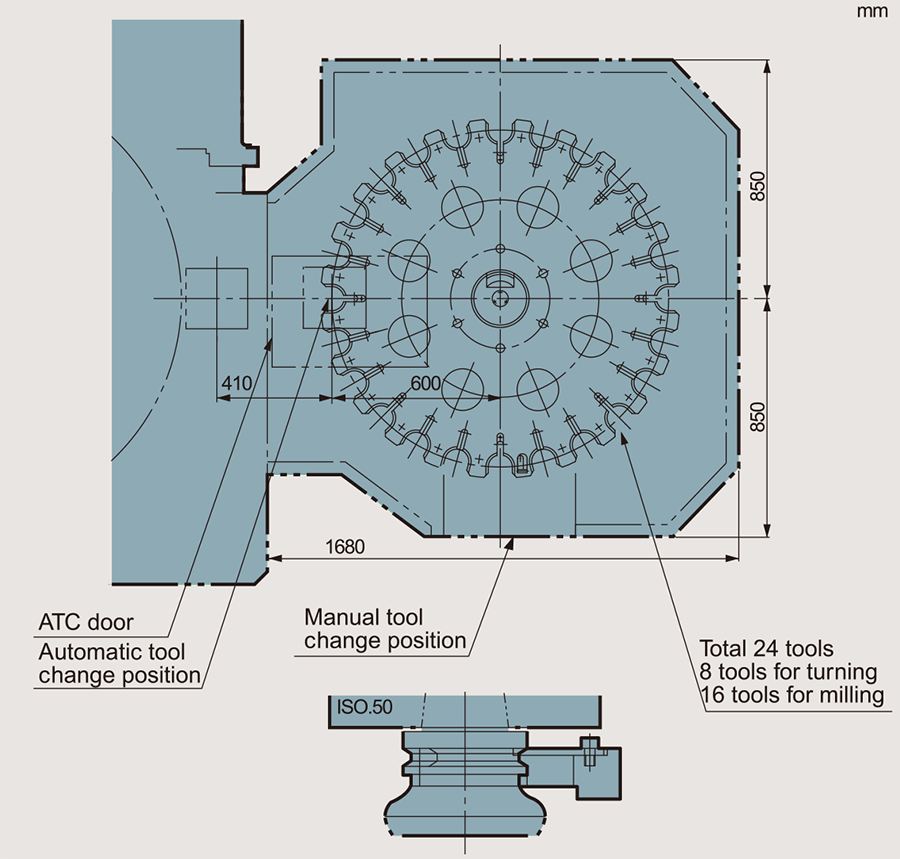

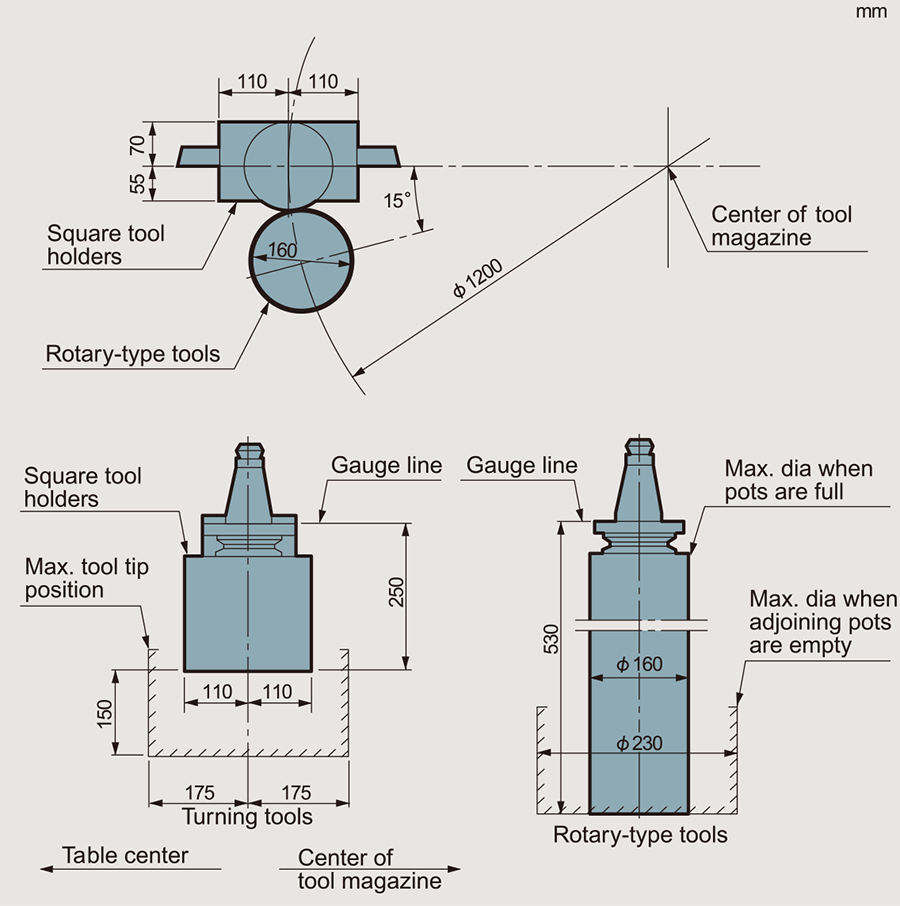

An automatic tool changer (ATC) and an automatic pallet changer (APC) are optionally available

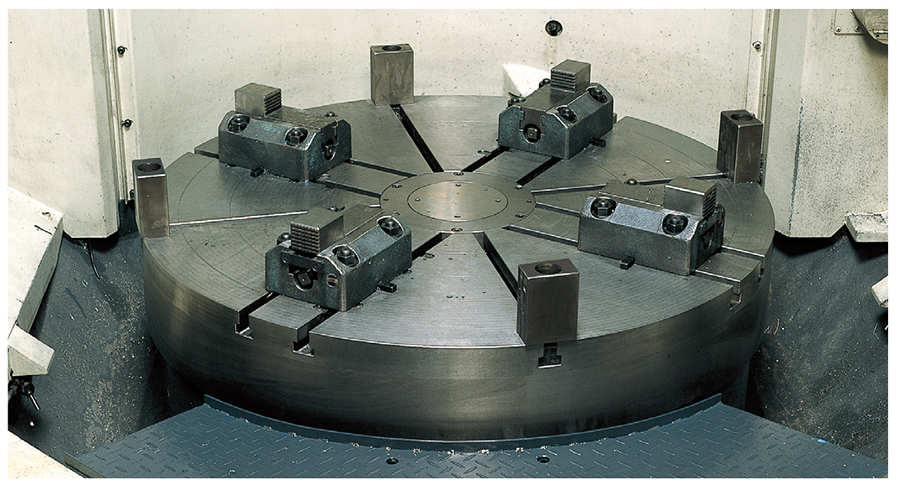

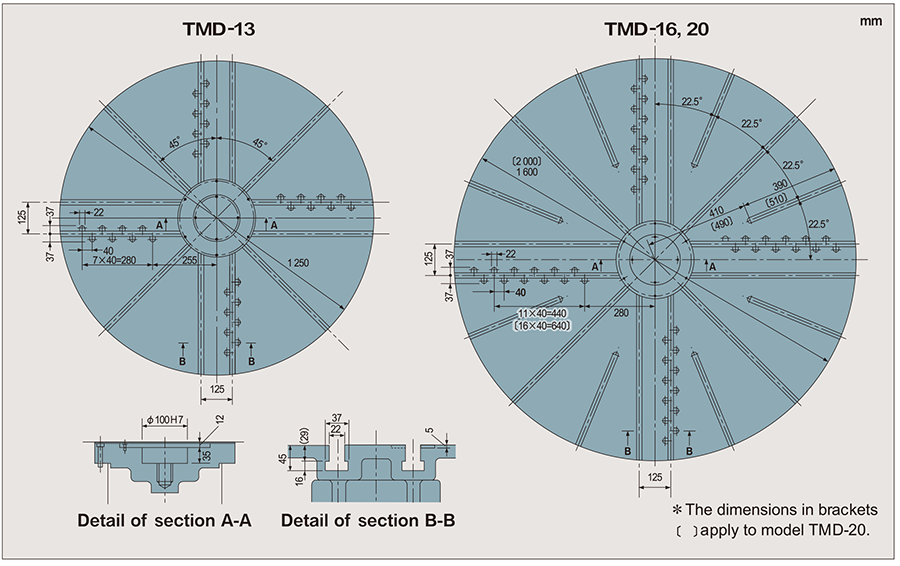

All of the major machine components are constructed of high-grade castings. The table has been provided with ample strength and size. The table is supported on a large-diamenter thrust ball bearing and tapered roller bearing arrangement. This type of arrangemet assures adequate support for extremely efficient, high speed heavy machining. In addition, the table is equipped with 4 independent manually-operated jaws and T-slots that guide and hold the workpiece in the required position.

The table and column are mounted on a common bed. Thermal distortion is minimized by a standard lubricant oil cooling system and the thermally symmetrical layout of ribs on the machine bed. Additionally, the table driving machanism is build into the rear side of the bed.

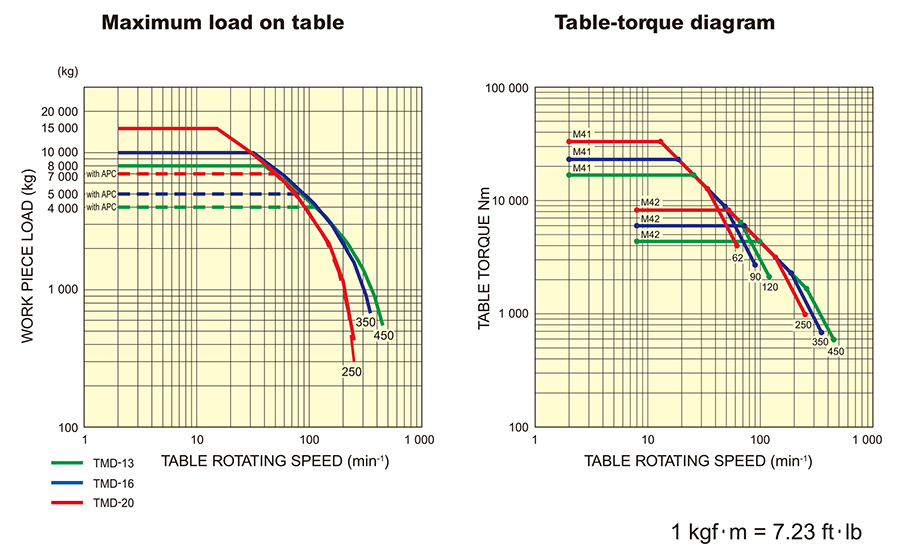

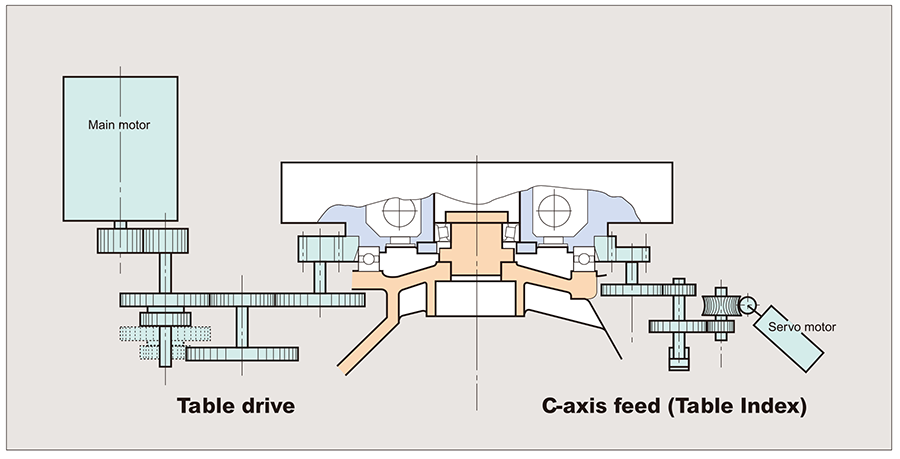

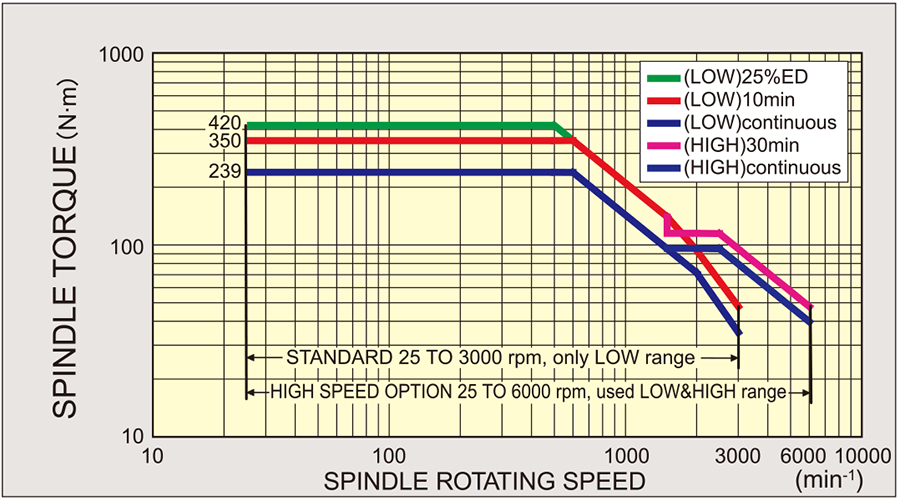

The main motor drives a large-diameter helical gear (ring gear) via two-range gear drive. Table speed change is performed by a two-range hydraulic shift and VAC motor control. The simplified gear mechanism with low heat generation is arranged symmetrically to enhance thermal rigidity. The C-axis feed pinion has a backlash eliminator for accurate table indexing. In the turning mode, this pinion is disengaged by the hydraulically shifted gear located in the C-axis feed gear box.

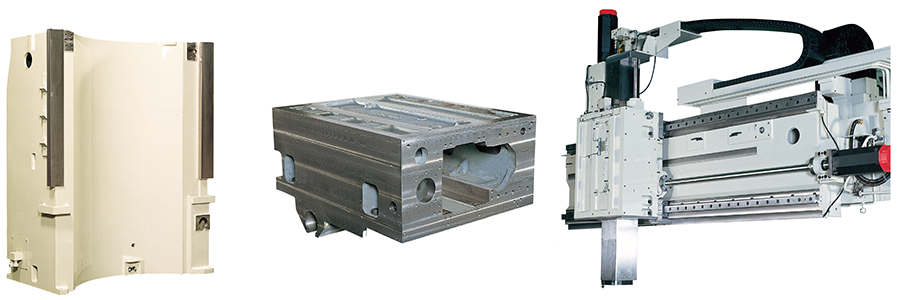

The extremely rigid and box-shaped symmetrical column has two guideways and crossrail linear guides are protected from chips and coolant with telescopic steel covers. The vertical movement of the crossrail is performed by a hydraulic cylinder in 250mm (9.84in) steps for precise positioning of up to a maximum of 500mm (19.6in) [750mm (29.5in) for TMD-20] using positive stops.

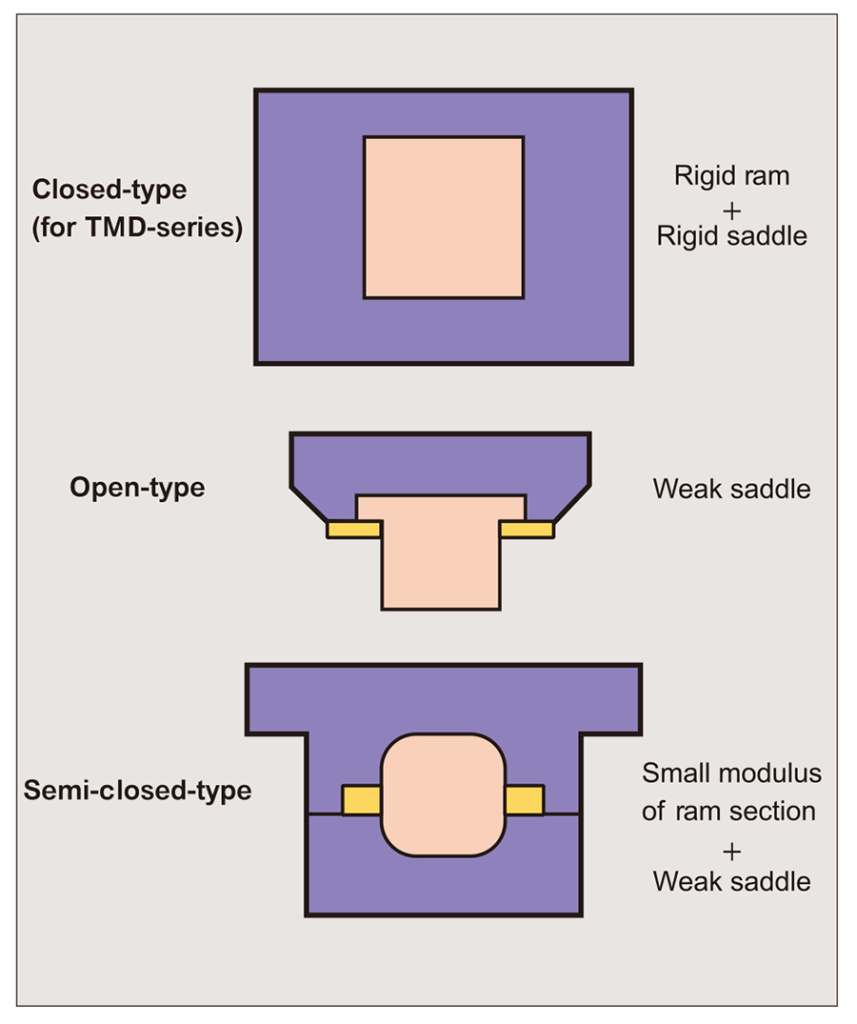

The maximum cutting force of the ram is more than twice that of our conventional machines even when the ram is extended to its maximum stroke. Liner machining by simultaneous control of the X and C axes is possible and the milling spindle motor is 20/15kW(30/20HP). The closed type single-block construction rail head encloses a 220×220mm (8.66×8.66in) square ram and other main machine components made of high-grade cast iron all assure high rigidity and quality machining.

Thermal disoplacement is halved, compared to other machines, resulting in dramatic improvement of the rail head positioning accuracy, and a thermally designed symmetricalcrossrail and motor position assure high thermal rigidity. Additionally, extremely rigid (X-axis) slideways assure high-speed and high accuracy operations.

The rail head is positined horizontally (X-axis) and the ram vertically (Z-axis) by means of large-diameter ball screws of which each is supported by special angular contact ball bearings. The X-axis slideways consists of liner guides and the Z-axis slideway is composed of non-metallic liners (Turcite B) to assure high positining accuracy, high-speed axis feed and heavy-duty operations. Tooling can be clamped/unclamped automatically in the spindle (ISO taper No.50) with the collet type pull stud and the spindle is driven by the AC type motor located at the top of the ram.

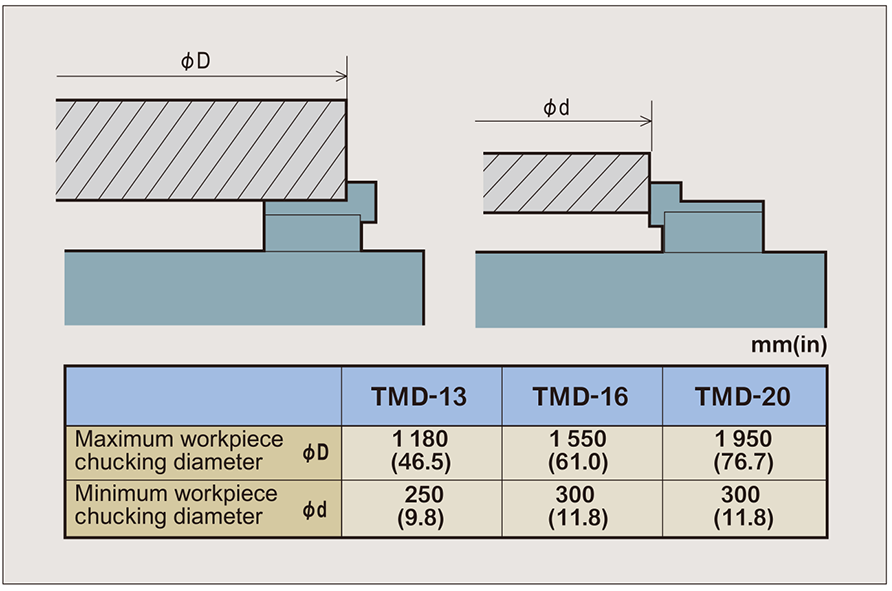

Four jaws with the follwing specifications are supplied as atandard accessories.

Standard Accessories

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.