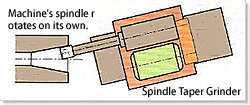

Our technical experts perform efficient work by using our spindle taper grinder.

Work schedule: 1 day (standard)

However, it depends on the degree of a dent and damage.

We support vertical- and horizontal-shaft equipment as well as other manufacturers’ products.

Phenomenon | Machine type | Before grinding | After grinding | ||

|---|---|---|---|---|---|

Entrance | 300 position | Entrance | 300 position

| ||

Jolting of the spindle is significant. | Vertical machining | 16 | 80 | 3 | 7 |

The taper dose not fit well. | Horizontal machining | 7 | 45 | 2 | 5 |

The spindle hit the workpiece. | Other manufacturer’s boring & milling machine | 13 | 60 | 3 | 8 |

Spindle overload due to a tool damage | Plano milling machine | 50 | 50 | 2 | 6 |

Restoring operation | Boring and milling machine | 20 | 70 | 1 | 4 |

Conditions

For the horizontal type, the distance between the table top and spindle center is 585 mm.

For the vertical type, the distance between the table top and the spindle nose is 700 mm.

Supported tapersNational taper No. 50/60

Morse taper No. 5/6

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.