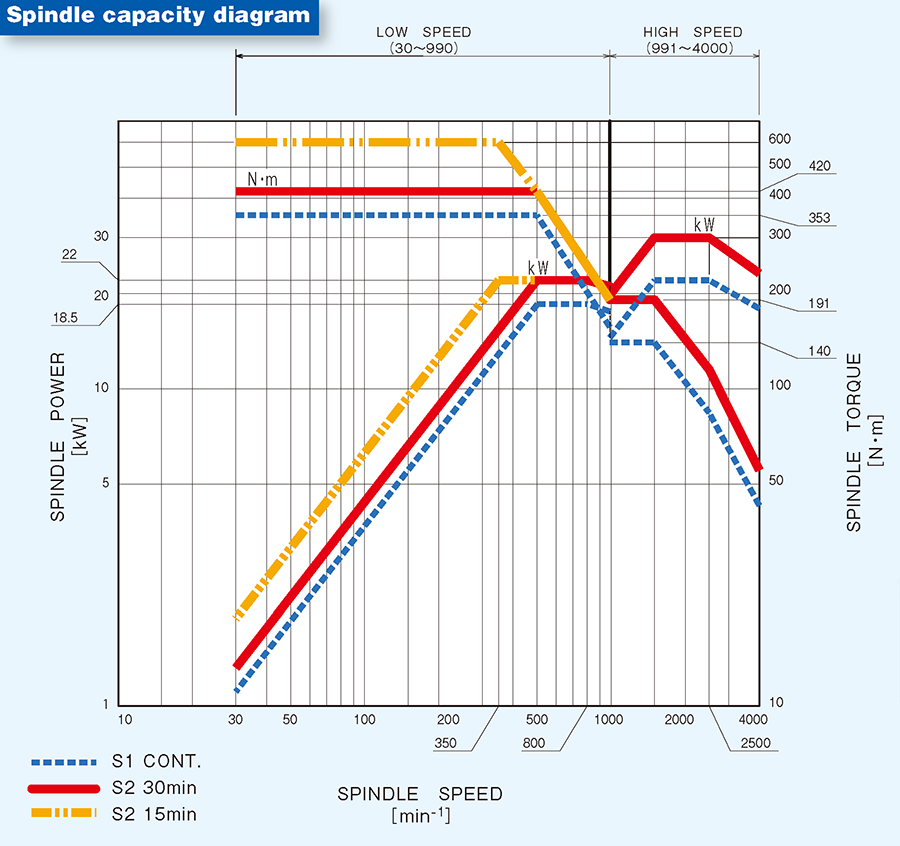

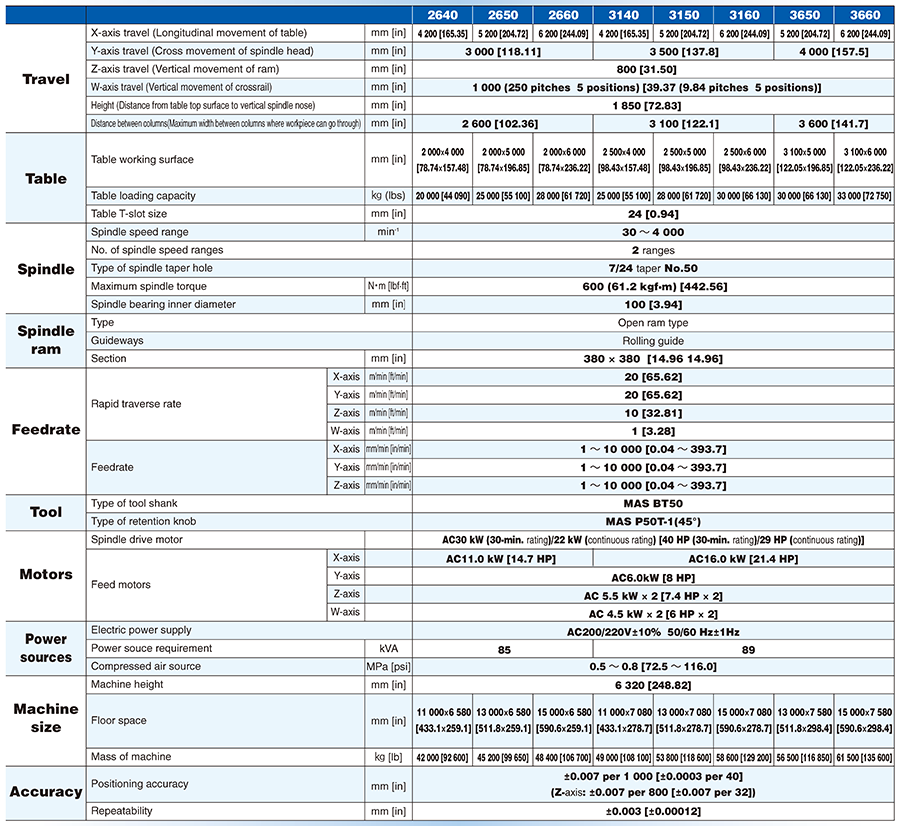

Standard 4,000min-1 Spindle

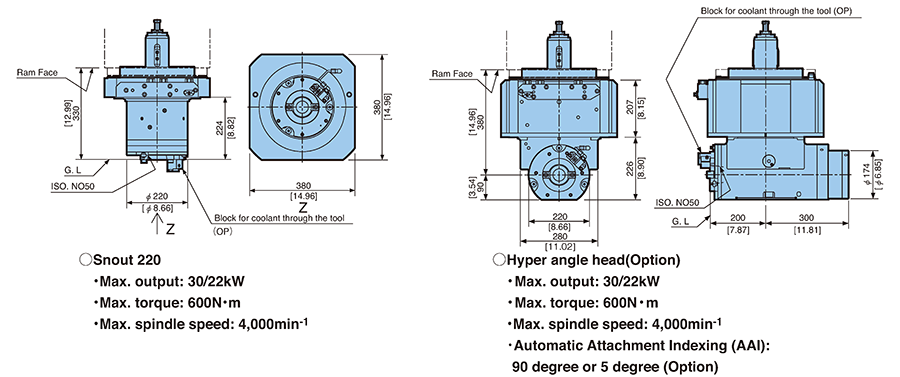

※(1) Automatic attachment indexing unit (AAI): Four (4)-position indexing by every 90°.

(2) Snout 220

※(3) Automatic tool changer (36-tool)

(4) Telescopic bed steel cover

(5) Crossrail bellows cover

(6) Telescopic lower side column steel cover

(7) Servicing (or maintenance) tools (attached with electric grease gun)

(8) Tool clamping/unclamping unit

(9) Oil mist lubrication unit (for gears)

(10) Hydraulic unit

(11) Ram cooling oil temperature regulator proportionate to room (or ambient) temperature (i.e., ram cooling unit)

(12) Plug receptacle for connecting an external device (single phase, 100 V, with grounding pole, capacity 3 A)

※(13) Balancing type pendant operation box

(14) W-axis NC positioning

(15) CNC system: FANUC Series 31i–B5

Note 1: For the items marked *, optional specifications can be selected. When this happens, relevant optional accessory is mounted in lieu of the standard accessory.

Note 2: The plug receptacle in Item 12 above is as per the JIS C8303. (It is used when the electric grease gun in Item 7 above is used.)

・Auto power OFF unit

・Work light

・Operator call lamp (LED lamp)

・Automatic tool changer (ATC)

・Maximum ATC tool length 600 mm [23.6 in]

・Type of retention knob: MAS P50T–2 (30°)

・Automatic workpiece changer (AWC)

・External program number search function

・Automatic attachment changer (AAC)

・Hyper angle head

・Five (5)-face cutter head

・Snout 190

・30° Head

・45° Head

・Incremental 5° automatic attachment indexing unit

・Installation parts (with leveling blocks)

・Chip conveyor

・Coolant recovery chute

・Block for coolant-through tool

・Coolant-through spindle

・Coolant unit

・Chip bucket

・Air blower function

・Mist coolant unit

・Automatic measuring unit

・Feedback system for closed-loop control

・Air compressor

・Air dryer

・Customer’s designated machine exterior painting color

・Free-arm pendant operation panel

・Stanchion type CNC operation box

・Preheat timer

・Pit type machine foundation (FL – 525 mm [– 20.7 in])

・Spindle designed for BIG-PLUS

・Power supply of different voltages

・Machining of reference slots on table surface

・Automatic greasing

・ATC splash cover

・Chip splash preventing half cover

・High-speed spindle

・Automatic tool length measuring unit

・Standard height + 500 mm [19.7 in]

・Cooler for machine control unit (MCU)

・Work light in MCU

・Earth leakage circuit breaker attached to main breaker

・Two (2) kinds of external M codes

・Z-axis thermal displacement compensation

・Additional axis control

・Spare elements

Multiple attachments allow variety of machining operations

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.