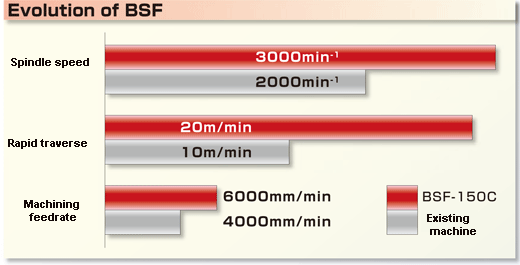

High efficient productivity has been achieved.

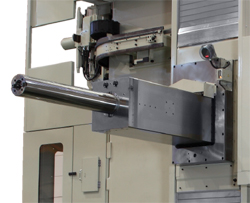

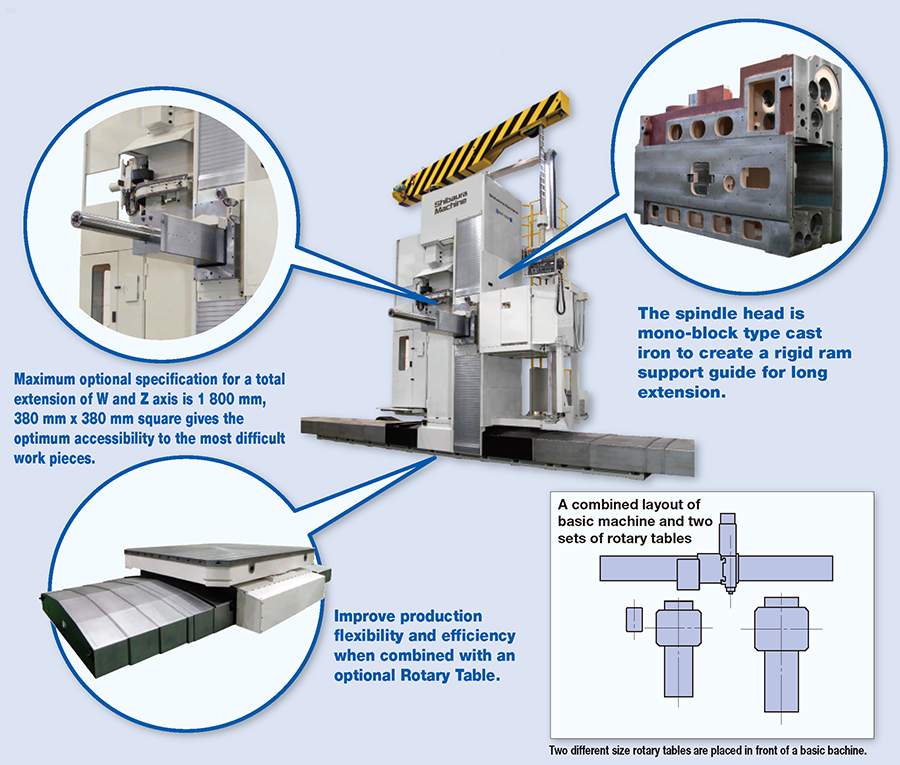

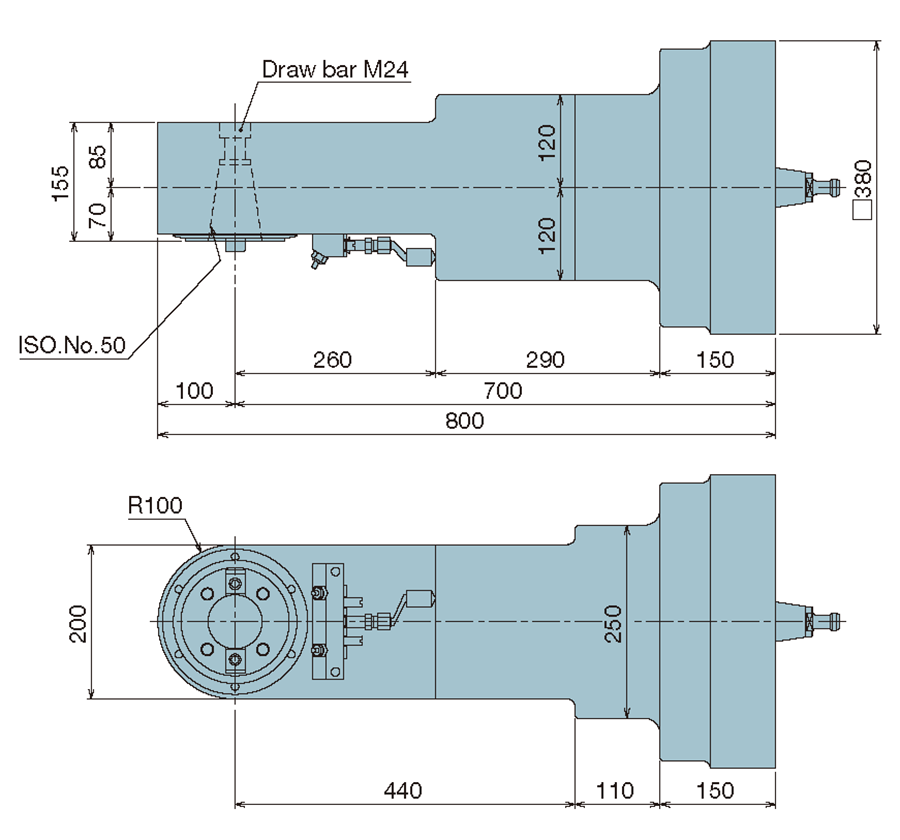

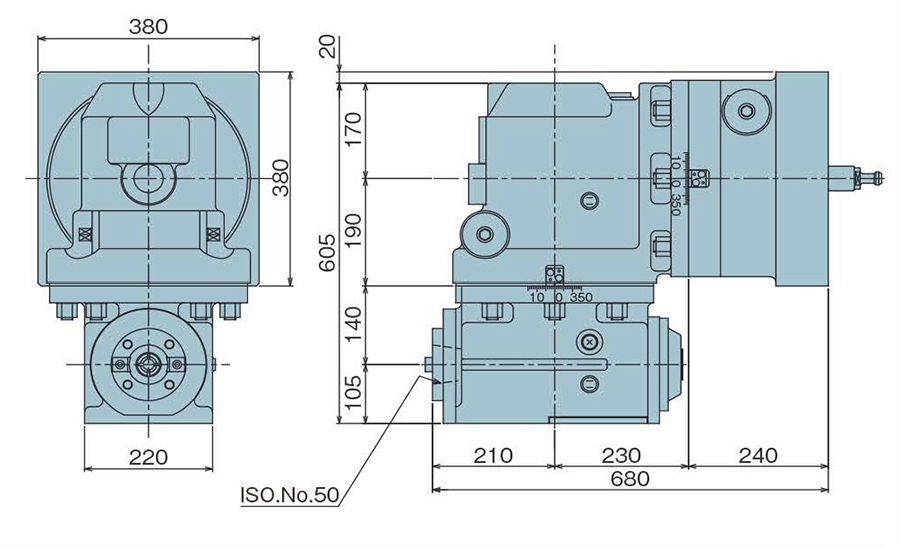

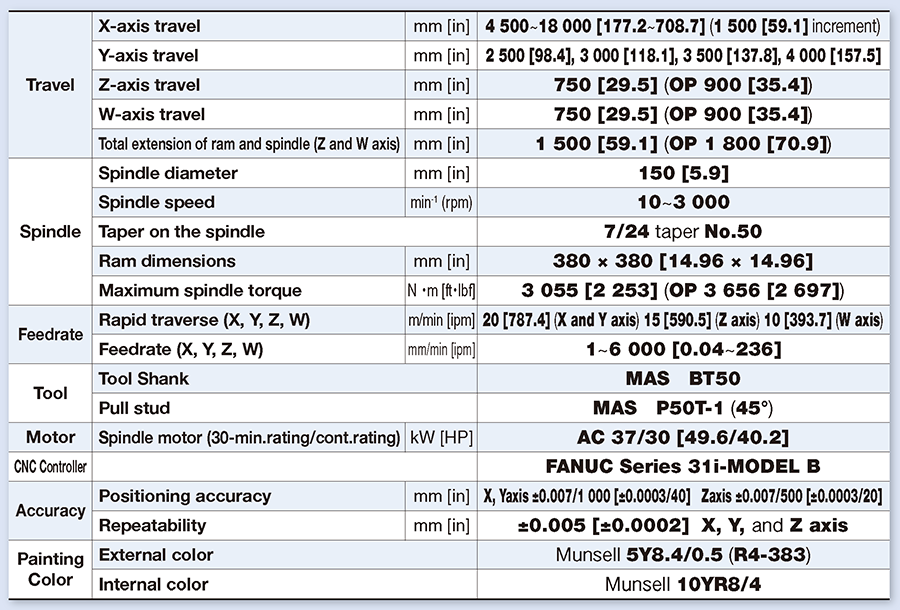

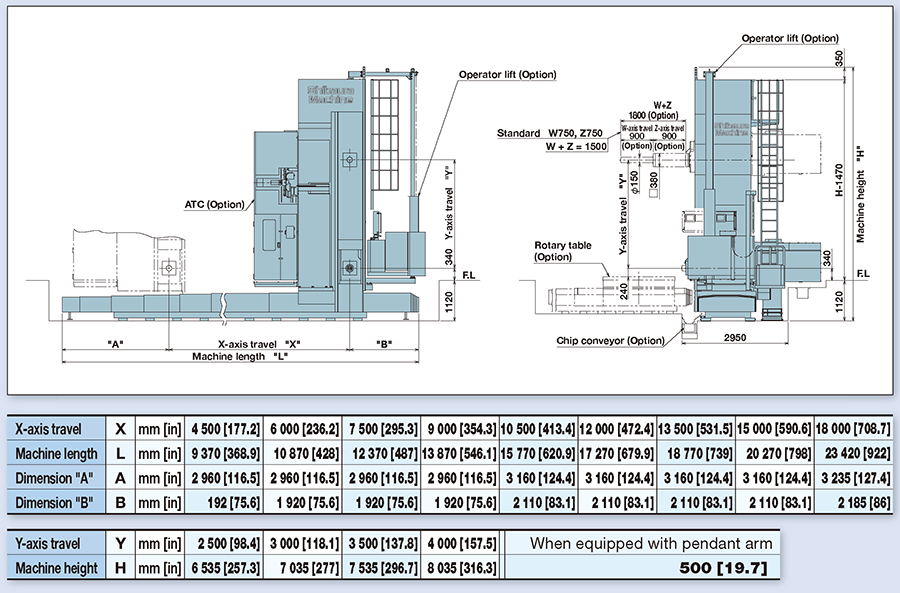

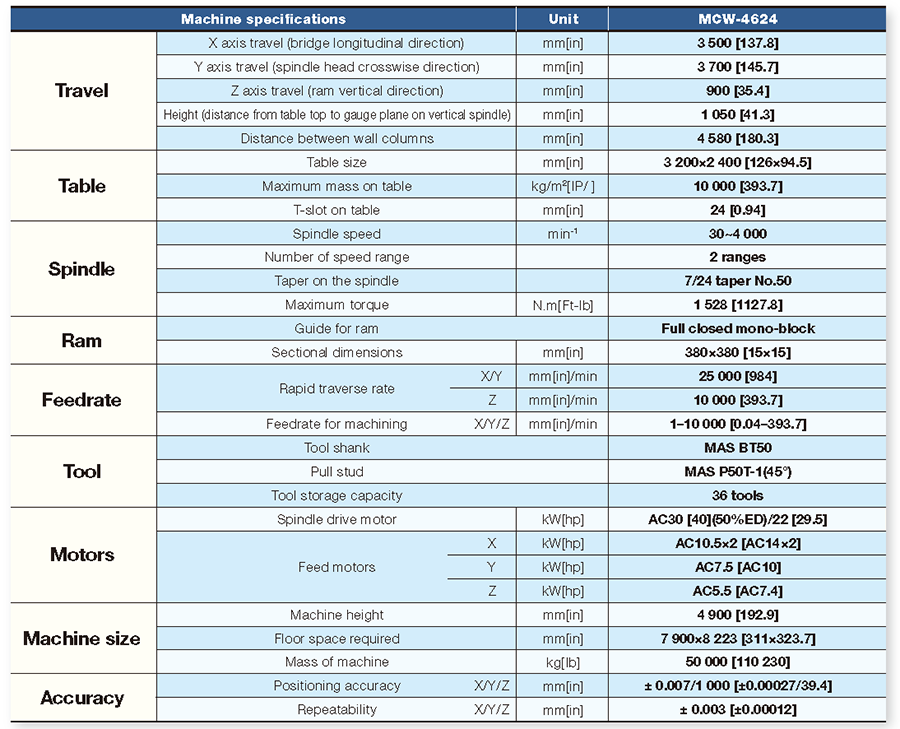

A total extension of W and Z axis is 1 800 mm in case of a special option, 380 mm x 380 mm square ram dimension gives optimum accessibility on a deep workpieces

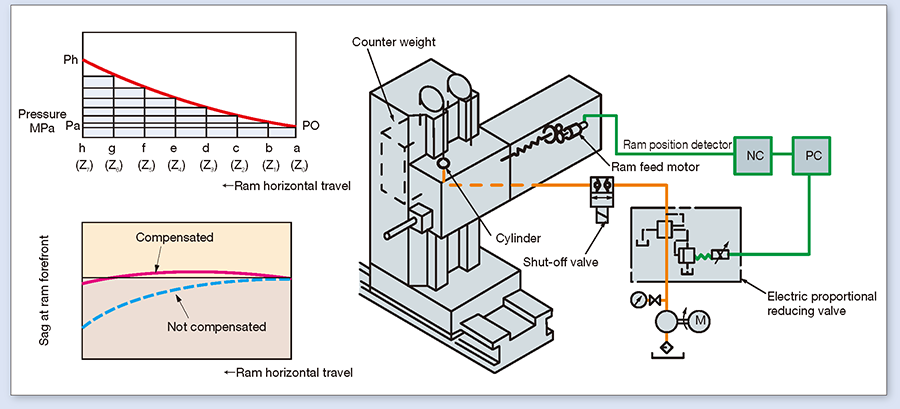

The Spindle head-center of gravity compensating device counteracts the primary cause of ram sag which occurs when changing center of gravity as the ram moves out. Tension on two balancing cables, front and rear, are automatically adjusted based on ram position to achieve optimum straightness when extending the ram.

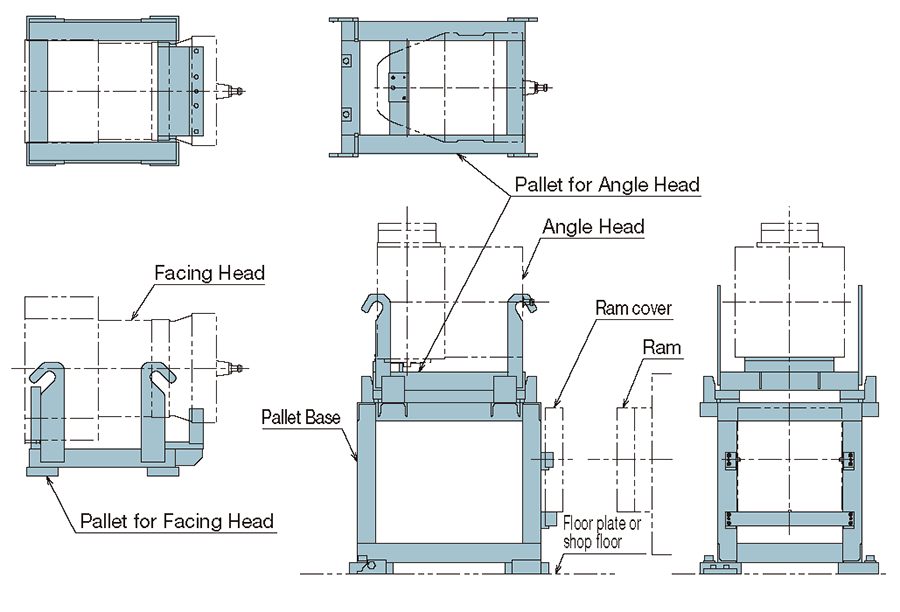

Other attachments can be supplied based on customer requirements.

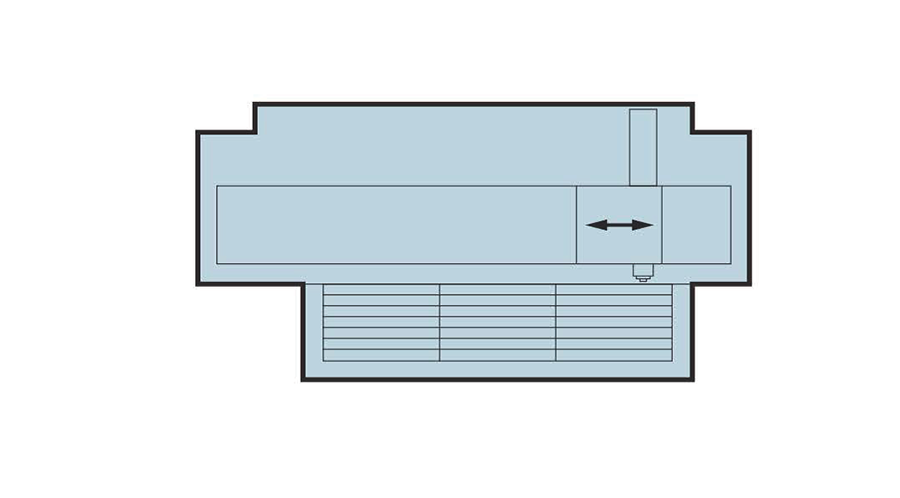

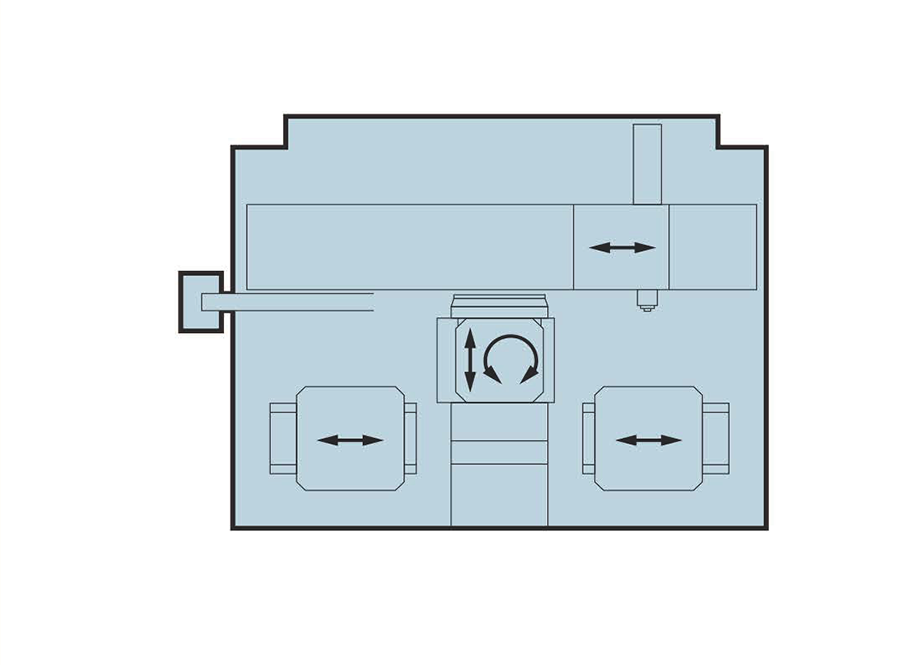

Floor plates provide minimum size and weight restrictions for work pieces and allow flexible work piece set-ups. The example sketch shows three floorplates arranged in lengthwise, in a single row along X-axis travel. Multiple floorplate arrangements are restricted only by available floor space and can be in crosswise or double row depending customers requirements.

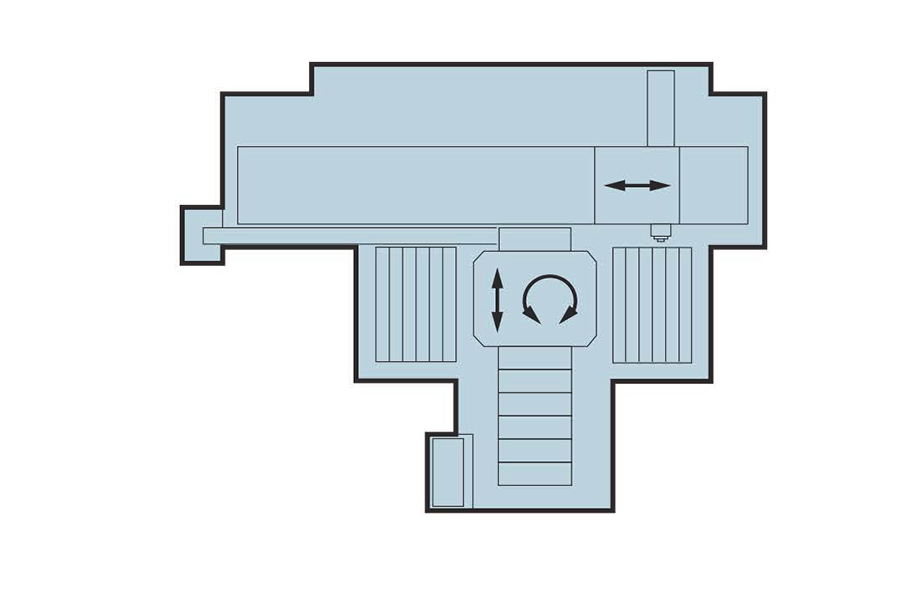

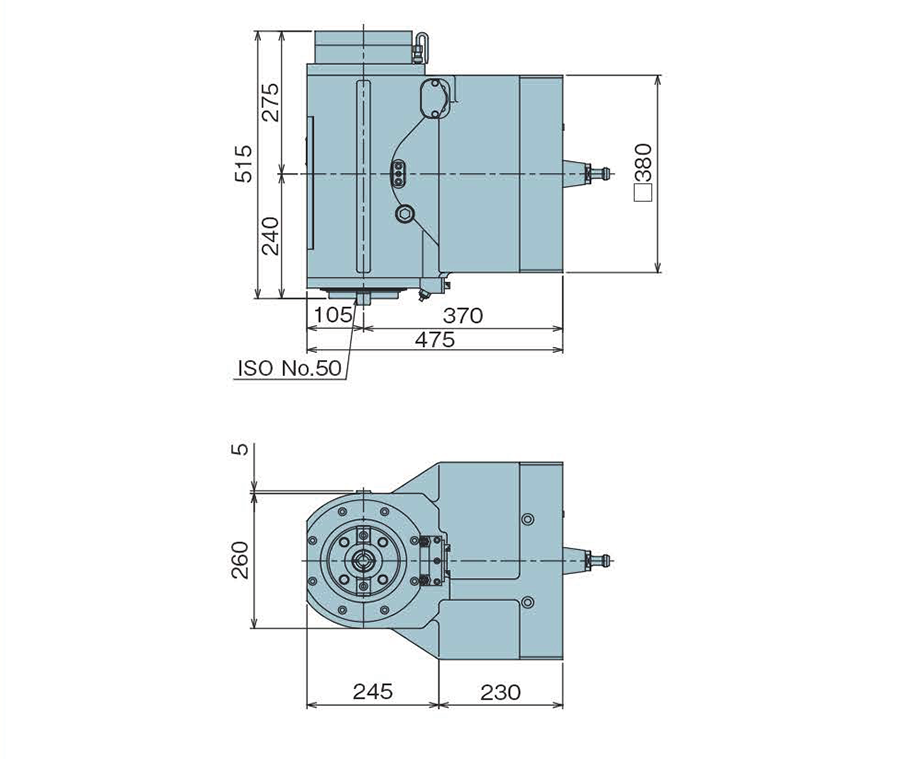

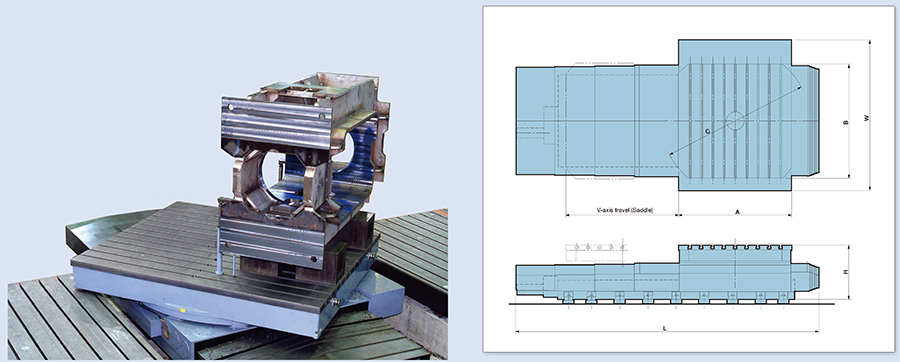

A Rotary Table provides great flexibility allowing machining on multiple face workpieces, boring on inverted face and high precision rotary milling and drastically improves productivity. Combined with floor plates, this specification provides flexibility to machine a wide variety of work pieces Multiple arrangements of this layout are available.

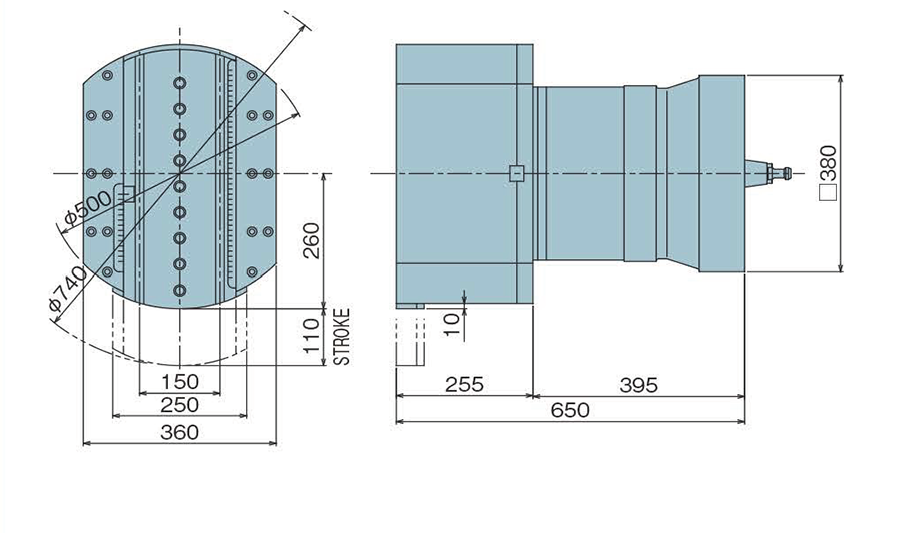

A Rotary Table equipped with pallet changer enhance performance and productivity by allowing unattended operation 15 percent of production time for a workpiece is used for set-up on average. By utilizing the pallet changer, set-up for the next work piece can be completed while machining the current workpiece reducing machine downtime to a few minutes to complete a pallet change, greatly increasing machine efficiency and multiple work piece flexibility.

Note: It changes with combination of Attachments

Example ; Angle Head and Facing Head

Example ; Angle Head and Facing Head

・An attachment located on the pallet base will be picked up onto the ram.

・An attachment on the pallet base should be replaced by means of crane, before mounting another attachment on the ram.

Manual pendant allows for easy manual operation. Levers for Jog, spindle, override rotary swiches, coolant/conveyor swtiches tool unclamp/clamp and more, allows for convienient operation in Manual mode and CNC mode. A portable handwheel unit allows fine movement in manual mode for set up and manual machining.

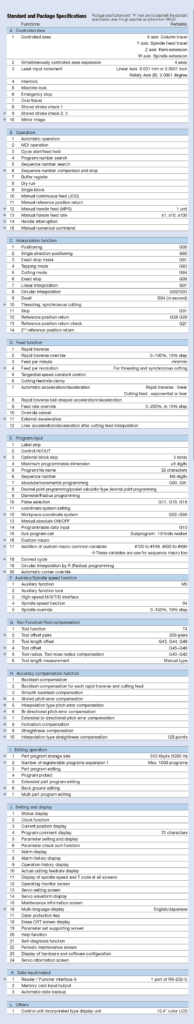

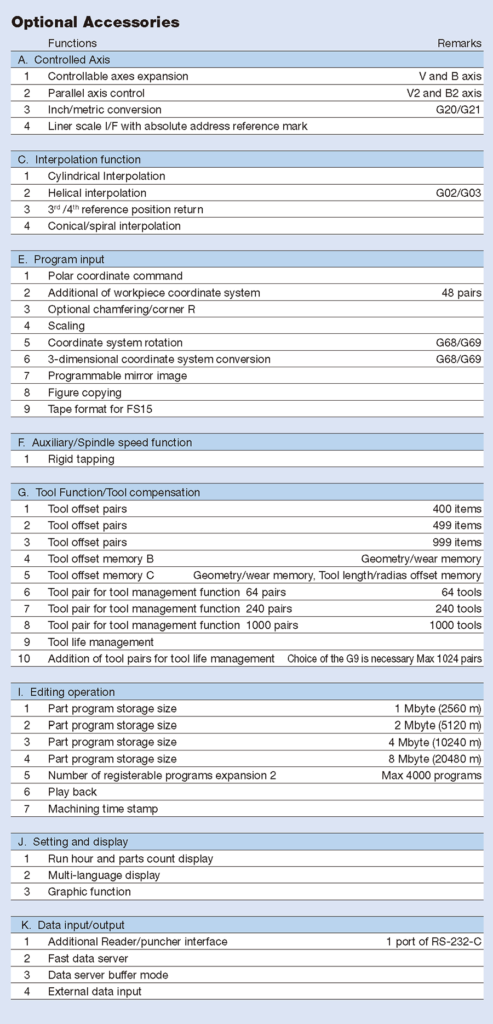

Essential optional functions for the FANUC control are included in the standard machine specifications. They include canned cycles, custom macro, etc.

Package specifications with “*” mark are included with the standard specification, even though specified as options from FANUC

CNC “FANUC Series 31i-MODEL B” is adopted on the machine for taking into consideration on grobal sales operation.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.