The EC-SXII series is a high performanceall electric injection molding machine that achieves “Precise and steadymolding” and “High productivity” by great improvement of thebasic performance given by newly developed mold clamping unit and injectionunit based on the concept similar to our previous EC-SX series.

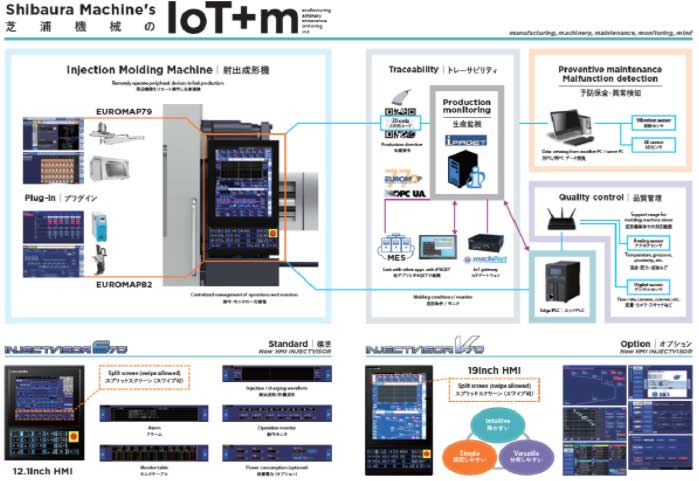

You can select fromtwo controllers the “INJECTVISOR-V50” and “INJECTVISOR-S51”.

V50 is a high performancecontroller having multiple molding functions and expandability.

S51 has addedmolding functions and improved production-managing functions compared to theprevious S50 controller.

We have a rich lineup from small size (30 tons) to super large size (2500 tons).

* 30 tons is EC30SXII.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.