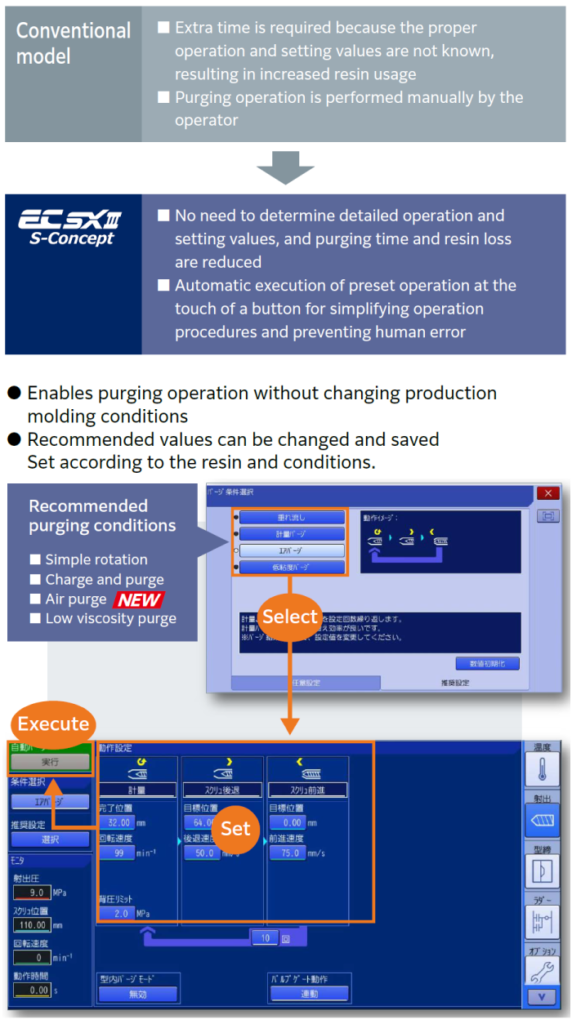

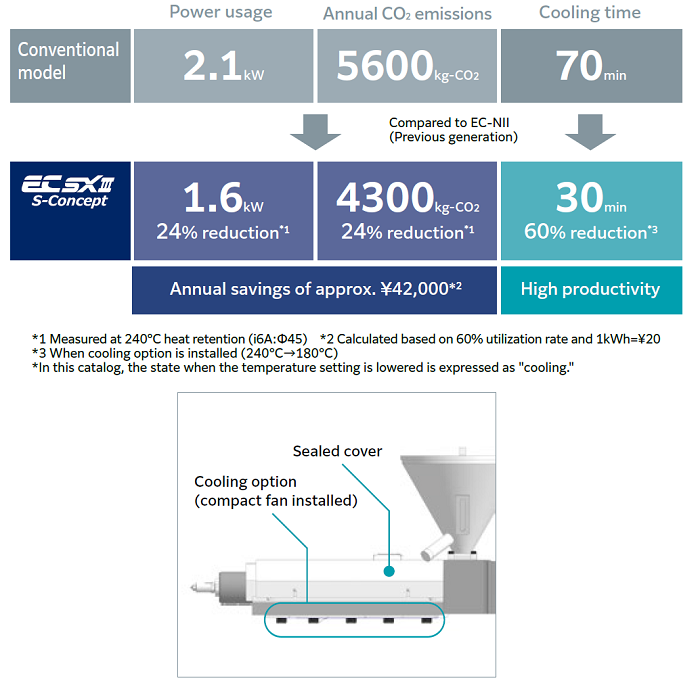

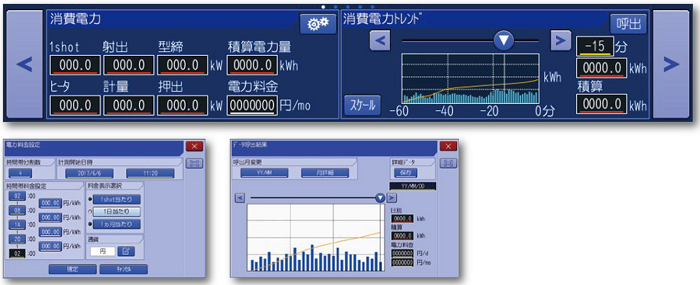

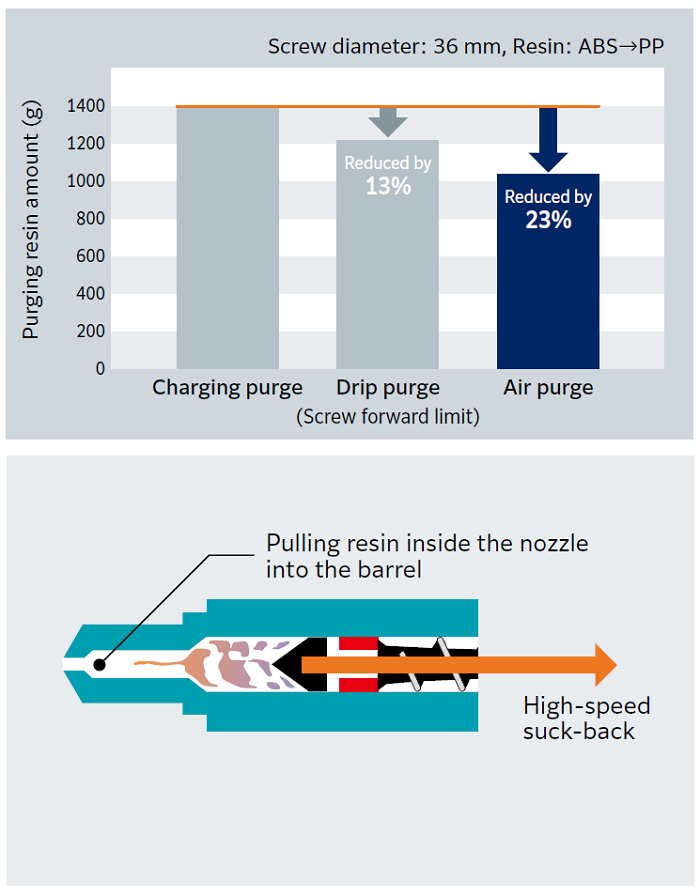

All-electric injection molding machine EC SXⅢ series S-Concept is a high productivity,

This is a new generation molding machine that achieves a high level of labor-saving and environmental friendliness.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.