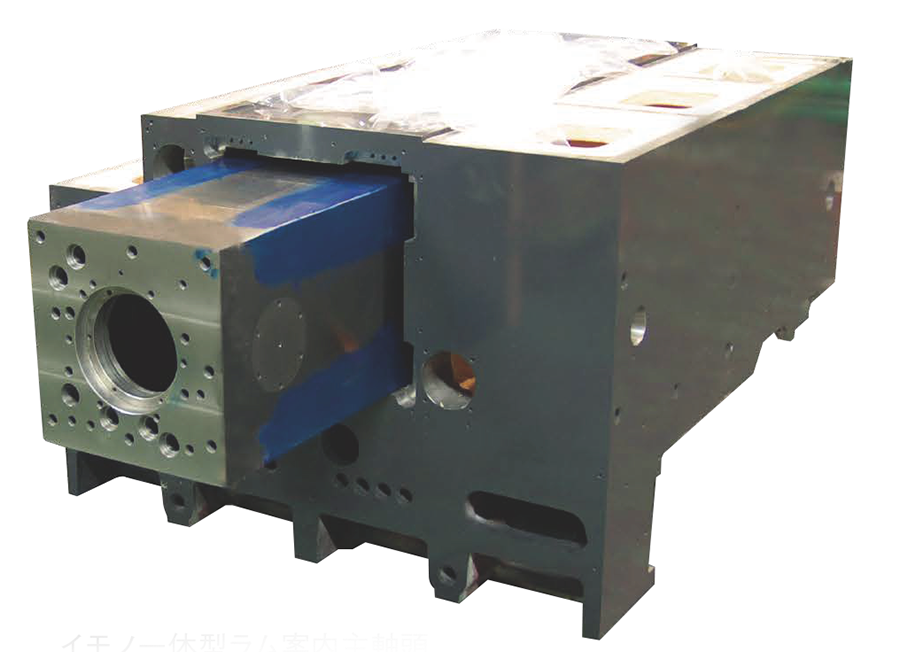

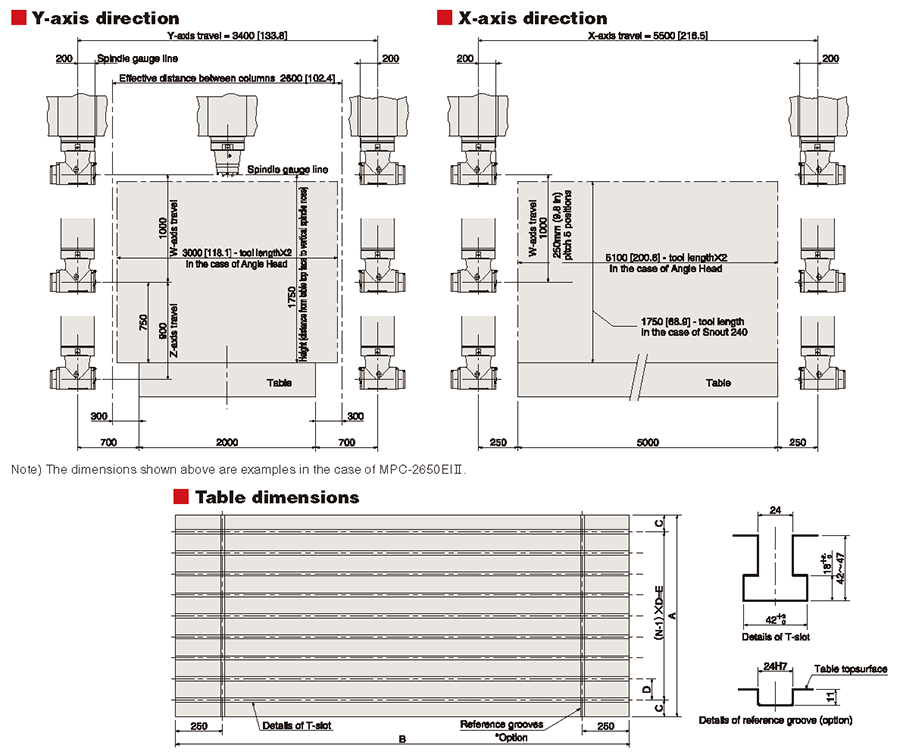

Angle head, 5-Face Cutter Head, 1° Indexing Head (option) is adopted to be capable of variety of machining

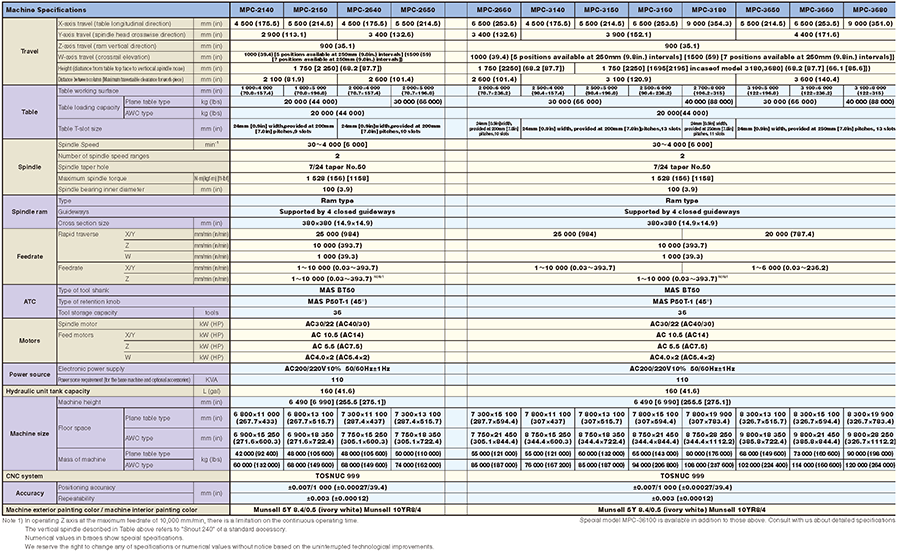

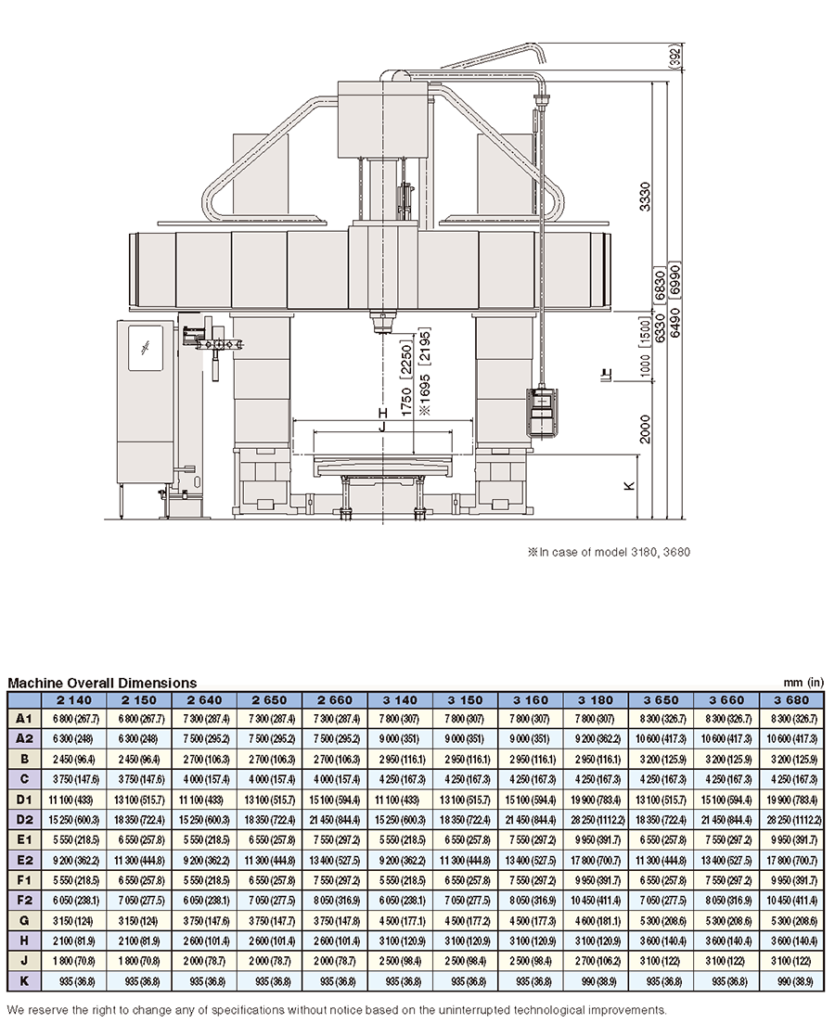

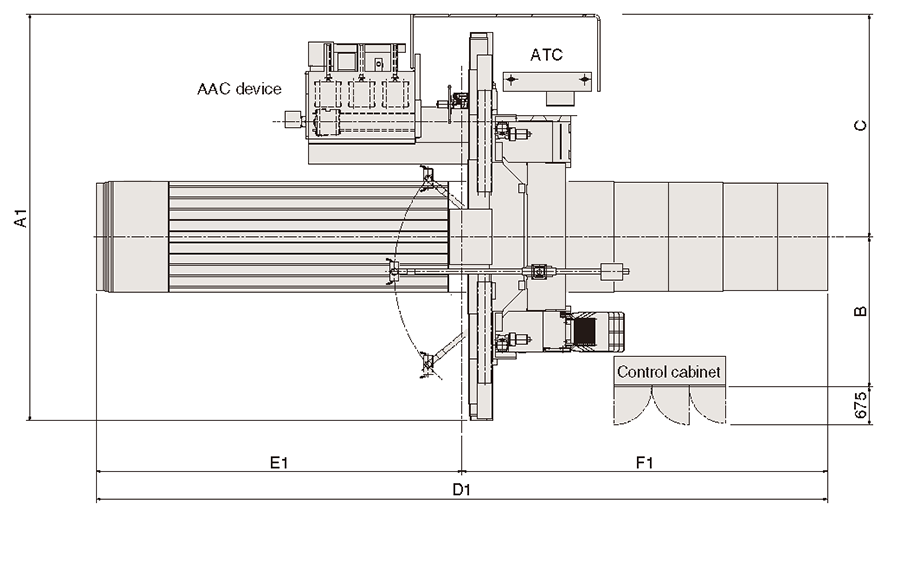

The machine size can be variously changed by combining a distance between columns such as 2100mm, 2600mm, 3100mm, or 3600mm with various table sizes.

The machine size can be variously changed by combining a distance between columns such as 2100mm, 2600mm, 3100mm, or 3600mm with various table sizes.

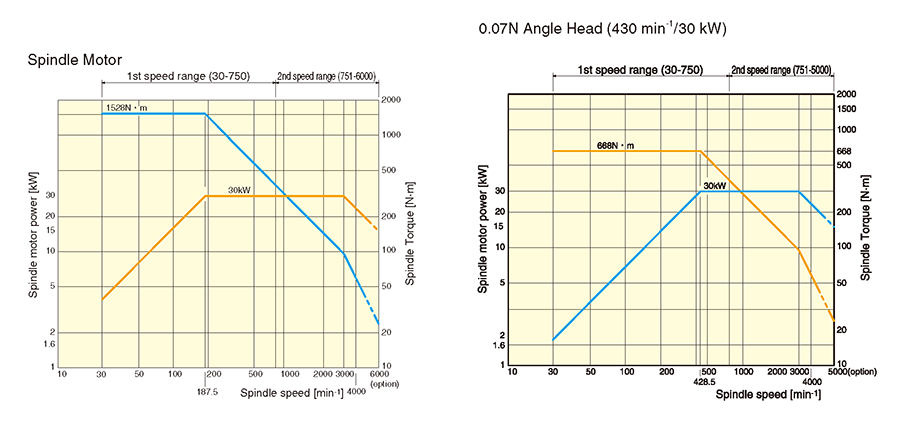

The spindle incorporated in the ram adopts maximum spindle speed of 4000min-1 (standard) or 6000min-1 (option). Each spindle having a large capacity of maximum torque of 1528 N-m exhibits excellent cutting performance

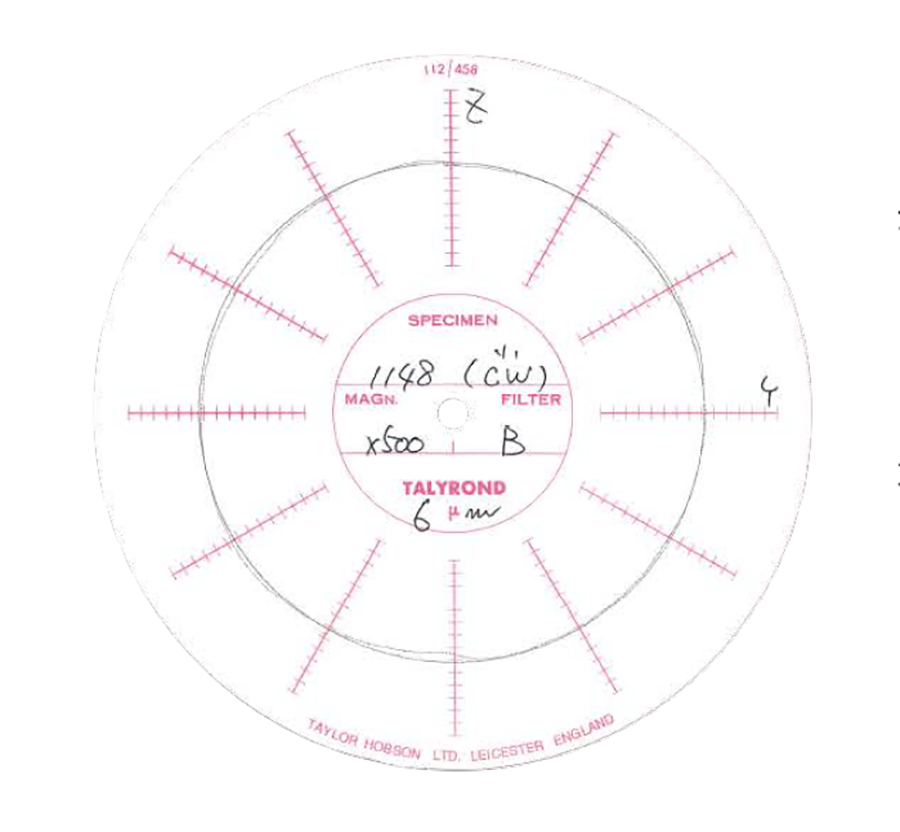

Vertical spindle (X-Y plane)

Roundness 0.02 (tolerance)

Actual value 0.006

Horizontal spindle (Y-Z plane)

Roundness 0.02 (tolerance)

Actual value 0.006

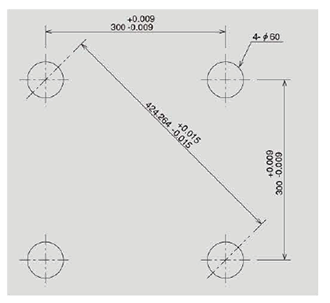

・Positioning accuracy (X, Y, Z)

±0.007/1000 mm (Actual value ±0.002/1000 mm)

・Repeatability (X, Y, Z)

±0.003 mm (Actual value ±0.001 – ±0.002 mm)

・Highly accurate straightness of table motion

0.005/1000 mm

Actual value | Guaranteed performance | |

|---|---|---|

In a vertical plane | 0.003/1000 mm | 0.005/1000 mm

|

In a horizontal plane | 0.002/1000 mm

|

In machining, various capabilities of the machine are required at all times.

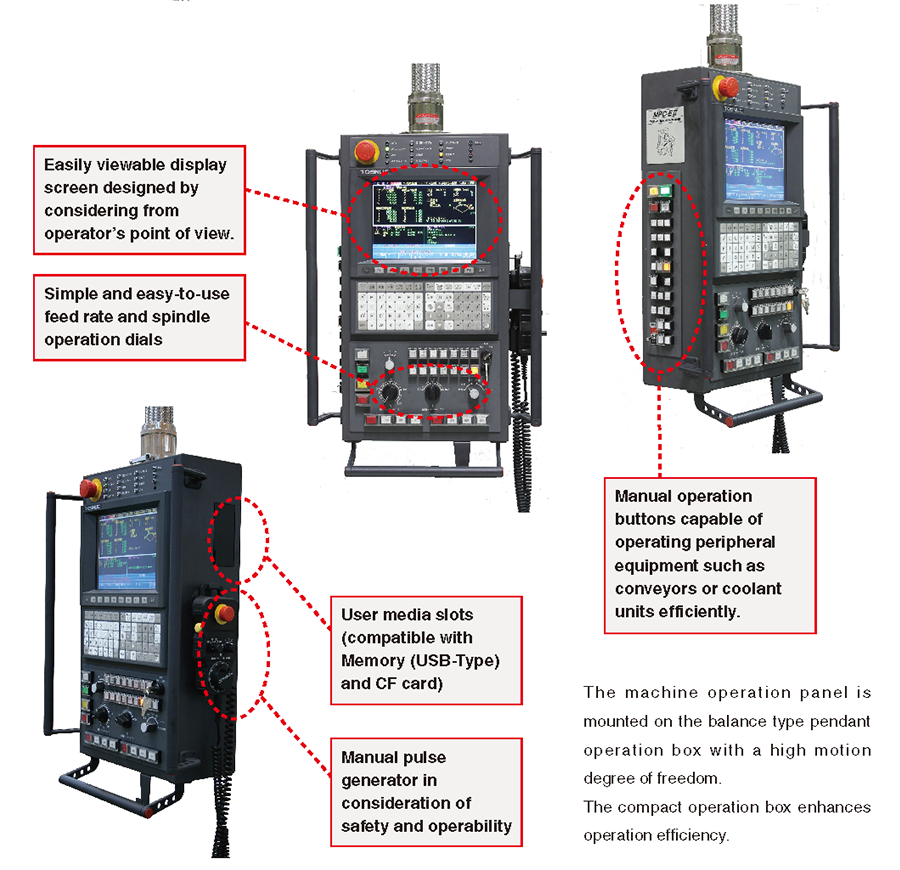

Not to mention the machining ability of the machine, the man-machine interface which controls the machine as the operator desires is also important.

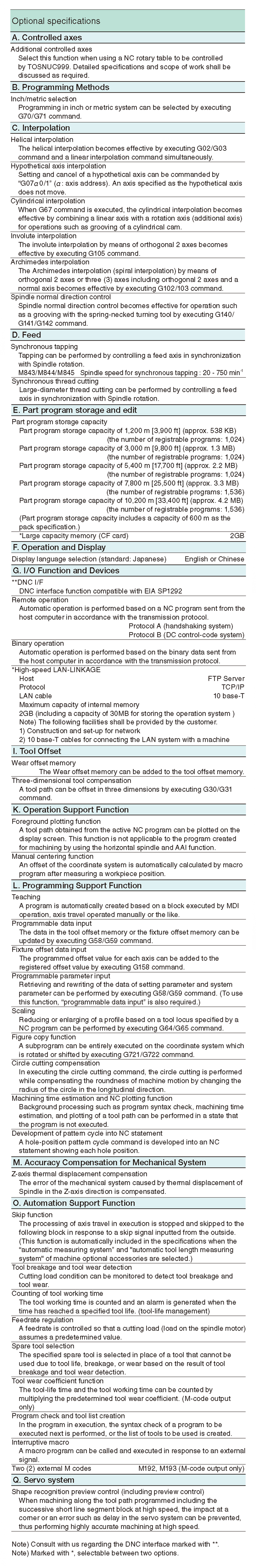

TOSNUC999 is the easy-to-operate CNC system developed for high speed and high precision machining based on the unique NC technique being integrated both mechanically and electrically and accumulated for years.

TOSNUC999 has various functions supportive of operators.

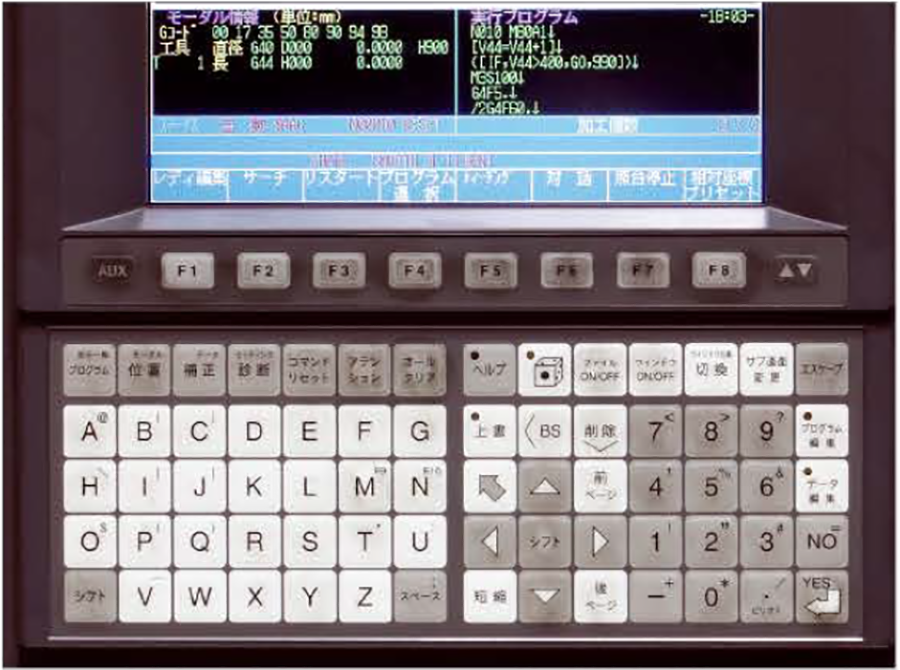

A display shown while machining or the contents of editing operation can be selected instantly by means of the independent keys without using the software menu.

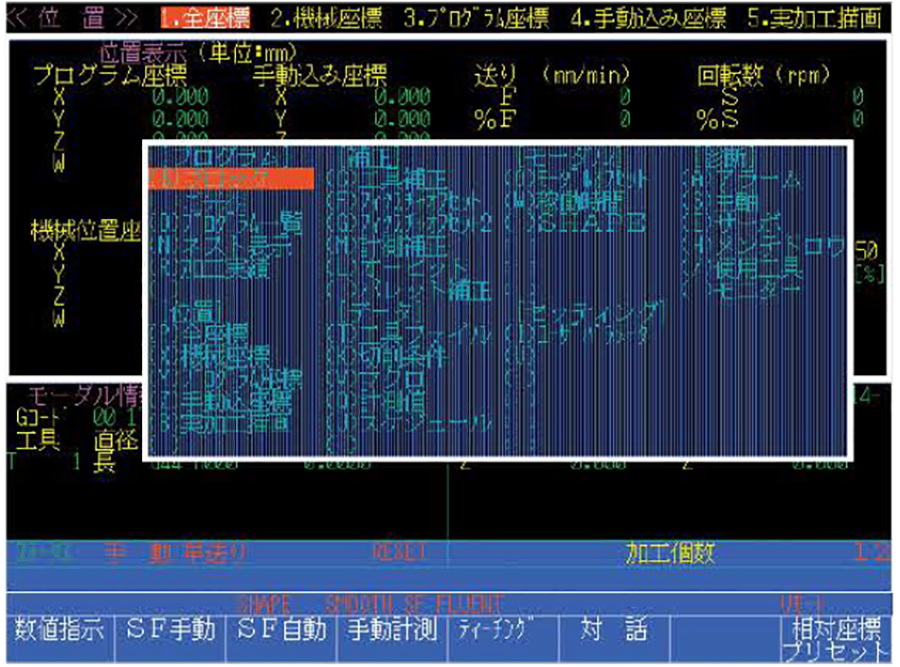

When a funct ion key is pressed for selecting the desired function, a window contai n i ng the menu corresponding to the function will appear or pop up.

Thus, any desire function can be selected without depending on a menu hierarchy or a complicated operation.

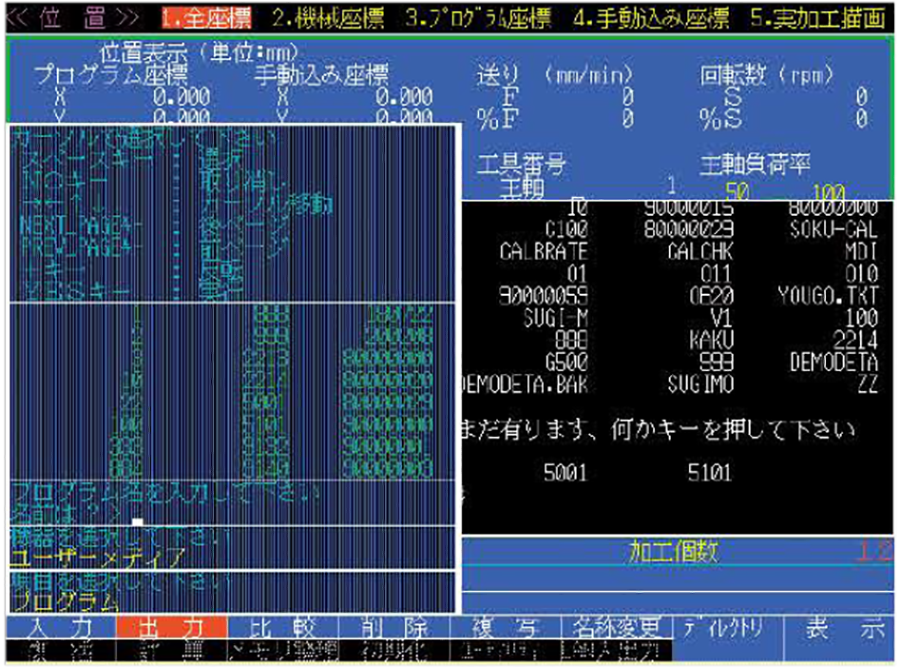

A full-fl edged multi-tasking and multiwindow system allows such operation as loading, dumping, comparing, deleting, and copying of programs or other data by opening a file window from any mode or screen.

For example, in automatic operation, while editing aprogram in a background, it is also possible to load another program into memory from the outside.

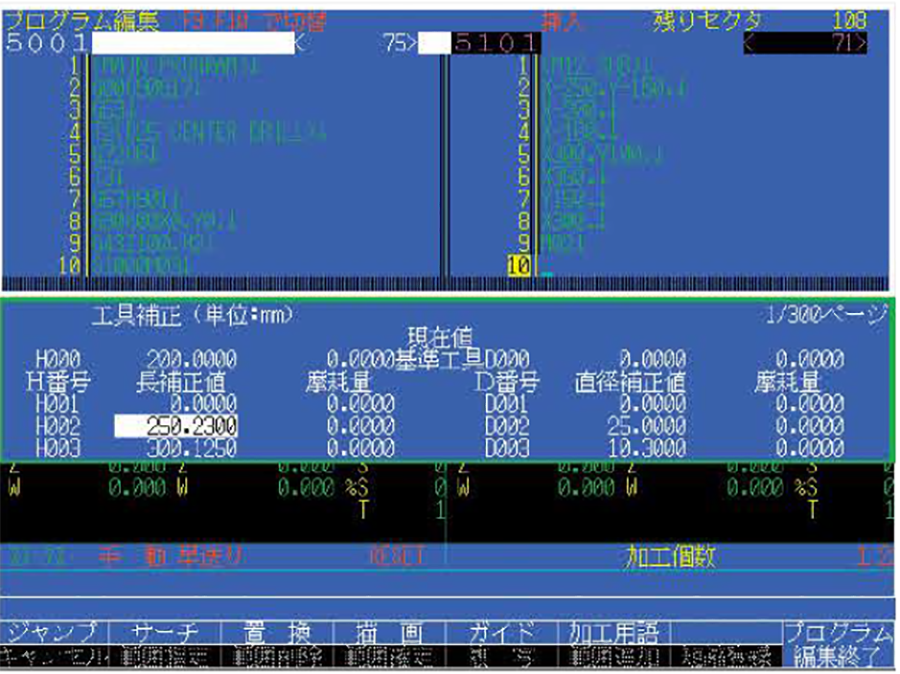

The display screen can be split in three to simultaneously display two programs and another data such as compensation values required for machining.

As it is possible to load or edit each data independently on these split screens, a new program can be created easi ly wi th reference to the already created program as if operating a word processor.

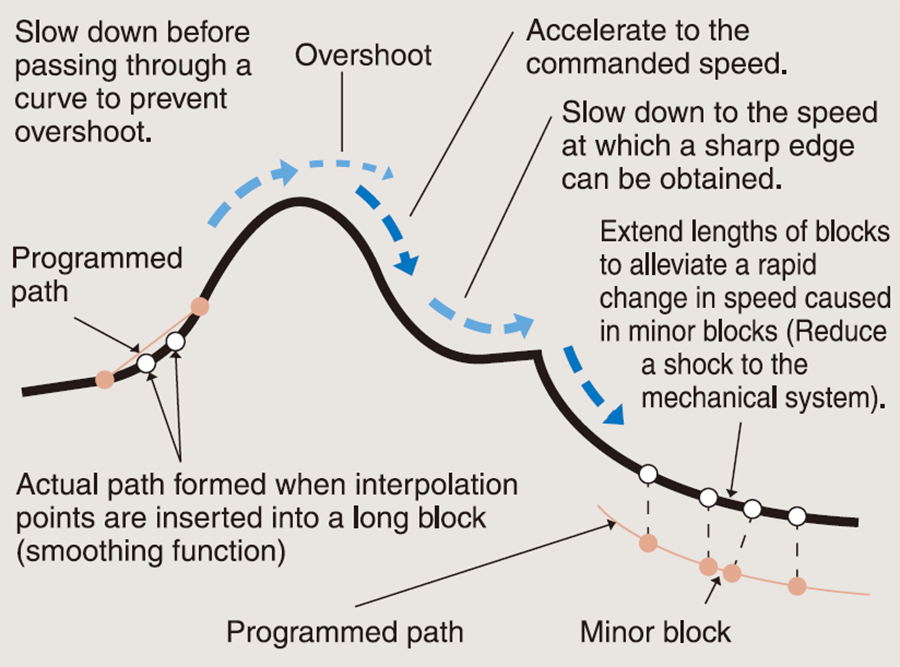

Generally, a contouring error decreases along with the increase of the servo gain. However, when the gain is increased, an overshoot of an axial position and vibrations caused by the increased acceleration applied to the machine adversely affect the cutting surface.

To prevent these phenomena, the preview control function has been developed based on the opt imal control theory thus minimizing the contouring error without increasing the gain.

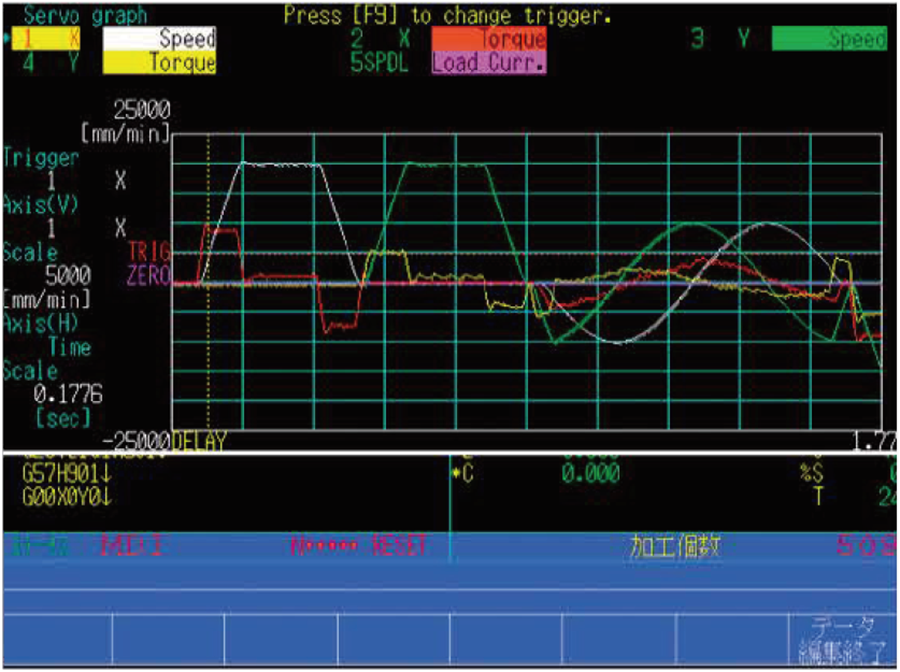

In adjusting the servo system for the machine equipped with CNC system, no convent ional measurement instrument is required. Each axisspeed and to rque characteristics or the like can be checked using the graphic function for servo adjustments.

Further, with the use of this function, load fluctuations of the spindle can also be detected, and parameters used for tool breakage detection can be set appropriately.

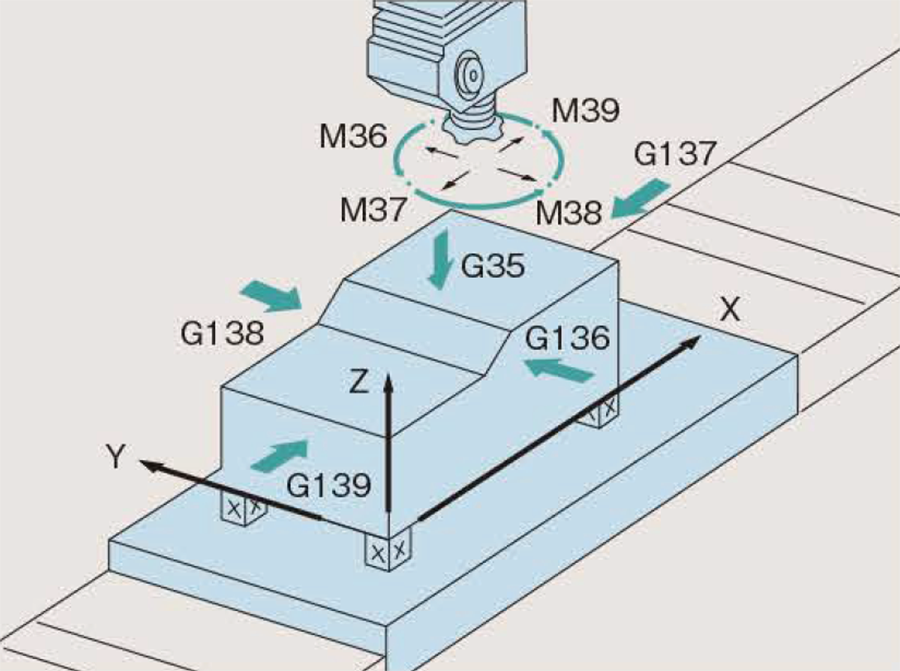

In machining the fi ve faces of a boxlike workpiece, an NC program on each face can be prepared based on the right-hand orthogonal coordinate system.

Further, each axis address (X, Y, and Z), sign (+/ -) and of fset (V and H spindle) are also changed automatically based on the indexing position of the attachment in use.

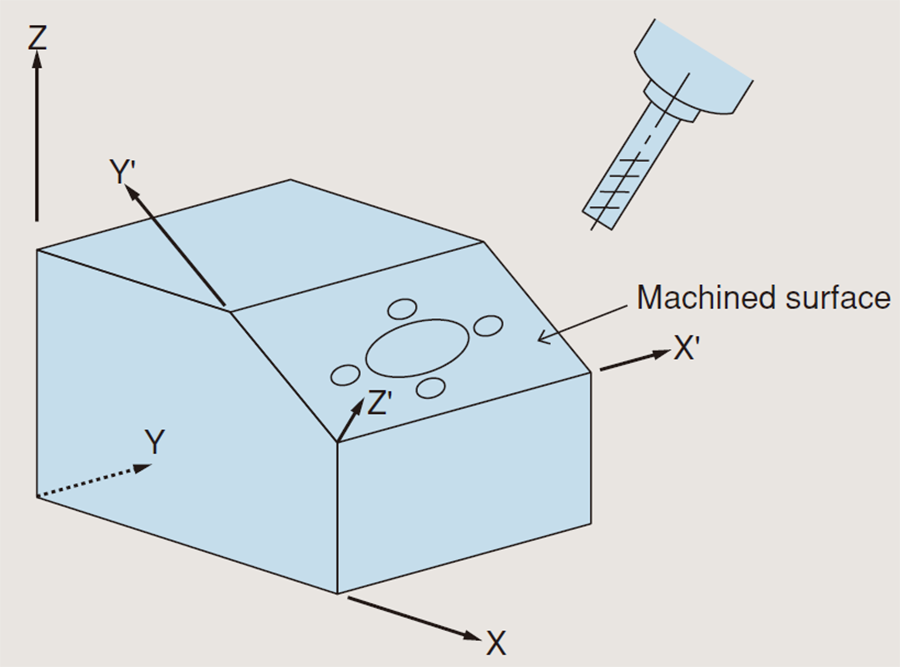

Beside or thogonal five faces, programming is easy even when the attachment is inclined at any angle.

For the inclined sur face, various funct ions such as canned cycle, circular interpolation, tool length offset and cutter compensation can be also used.

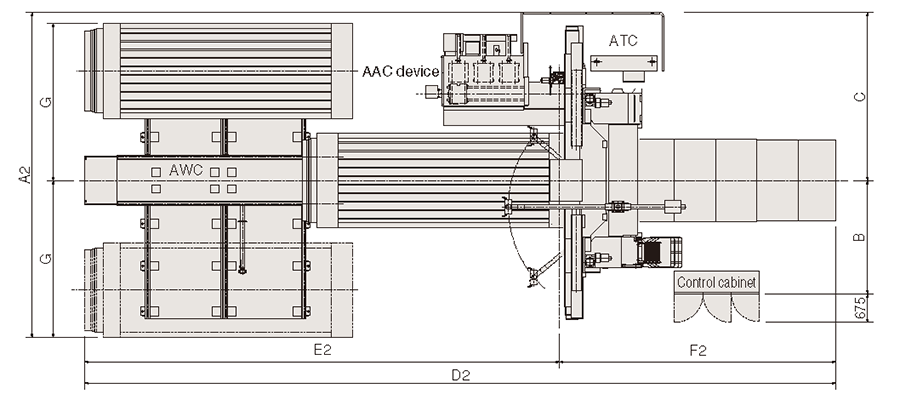

● X-axis travel: Table length + 500 mm [19.7 in.]

● Y-axis travel: effective distance between columns + 800 mm [31.5 in.]

● W-axis travel: 1000 mm [39.4 in.] (crossrail elevation: 5 positions available at 250 mm [9.8 in.] intervals)

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.