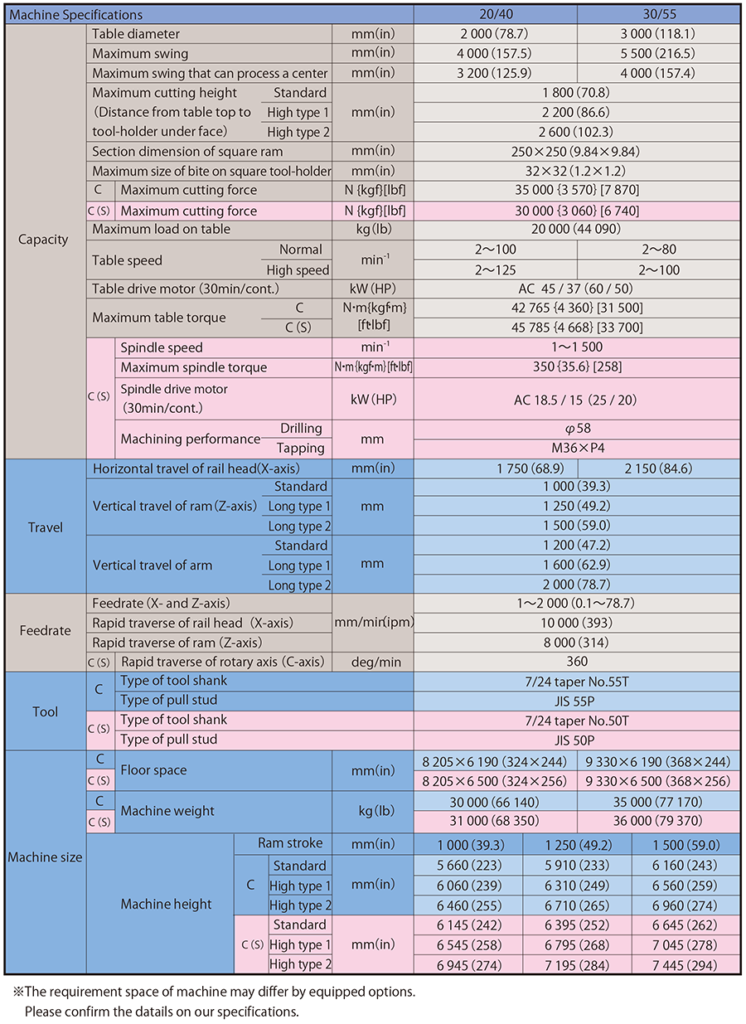

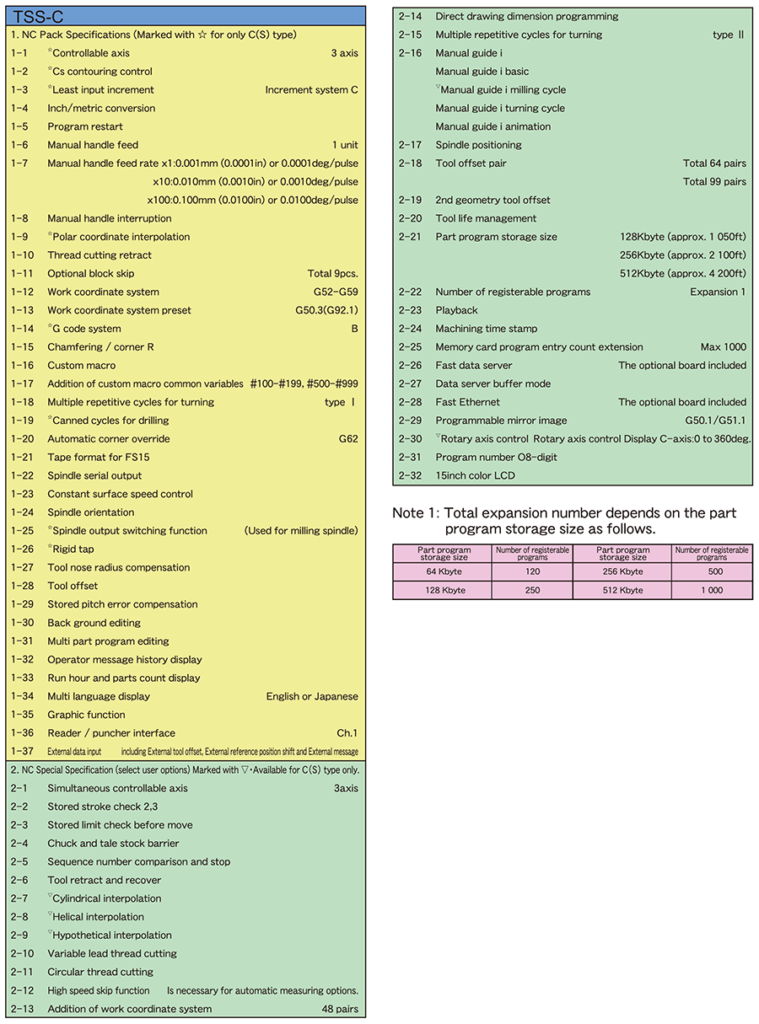

TSS-C(S) model also performs machining operations as boring, drilling and tapping

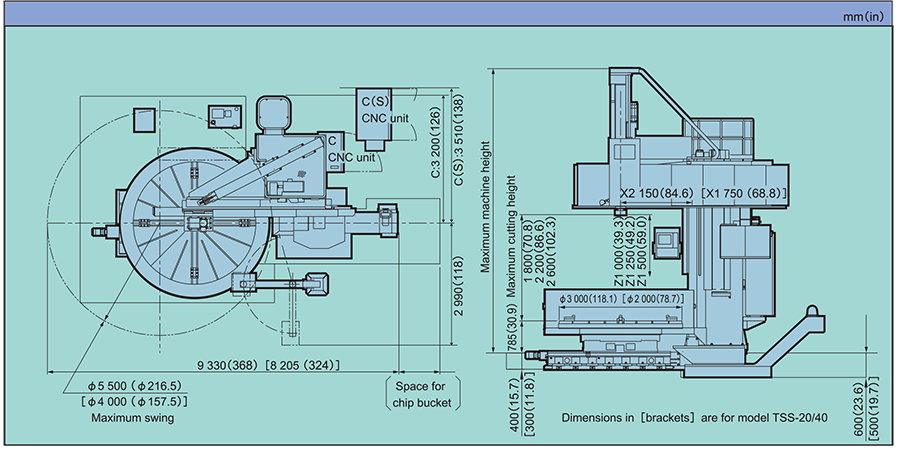

TSS-C series preserves the best features of single-column machine. The stationary column and the moving table perform stable and accurate machining of large-diameter workpieces, larger the table diameter

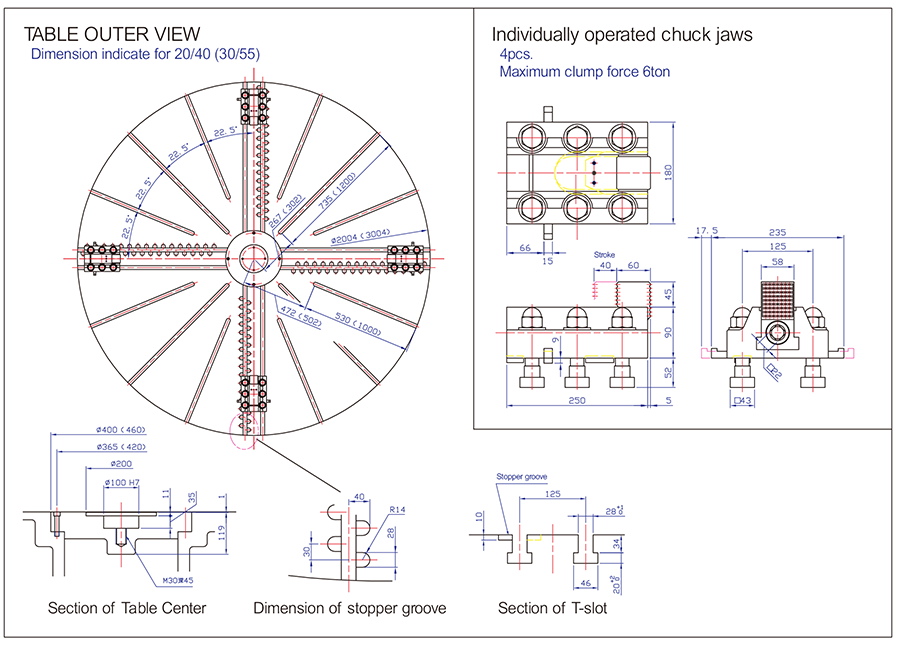

The table supported by two roller bearings stabilizes heavy-duty machining operations at high speed even at machining of large-diameter work

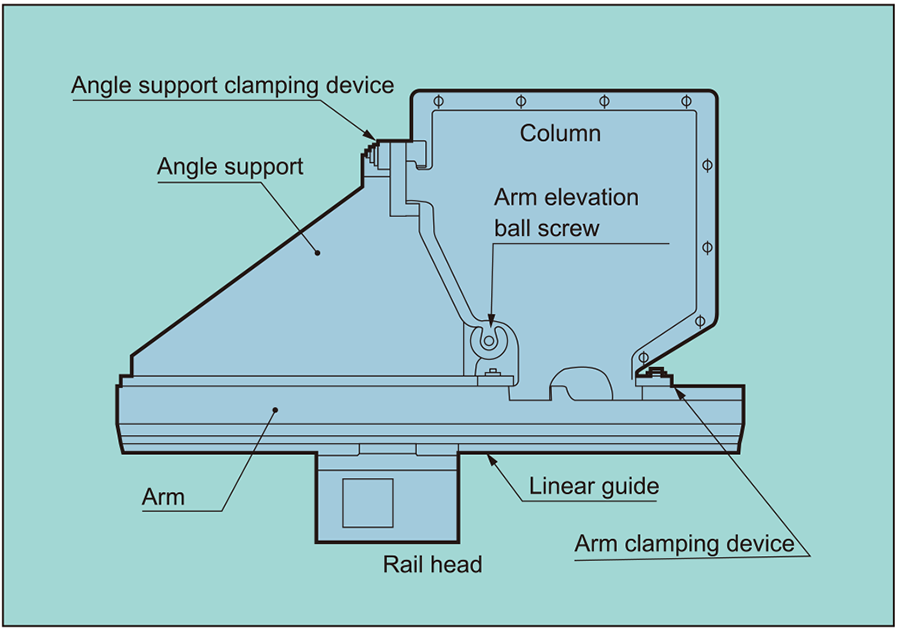

Roller type linear guides are employed for the rail head guideway (X-axis) to assure smooth high-speed feed and micro feed. The positioning accuracy has also increased

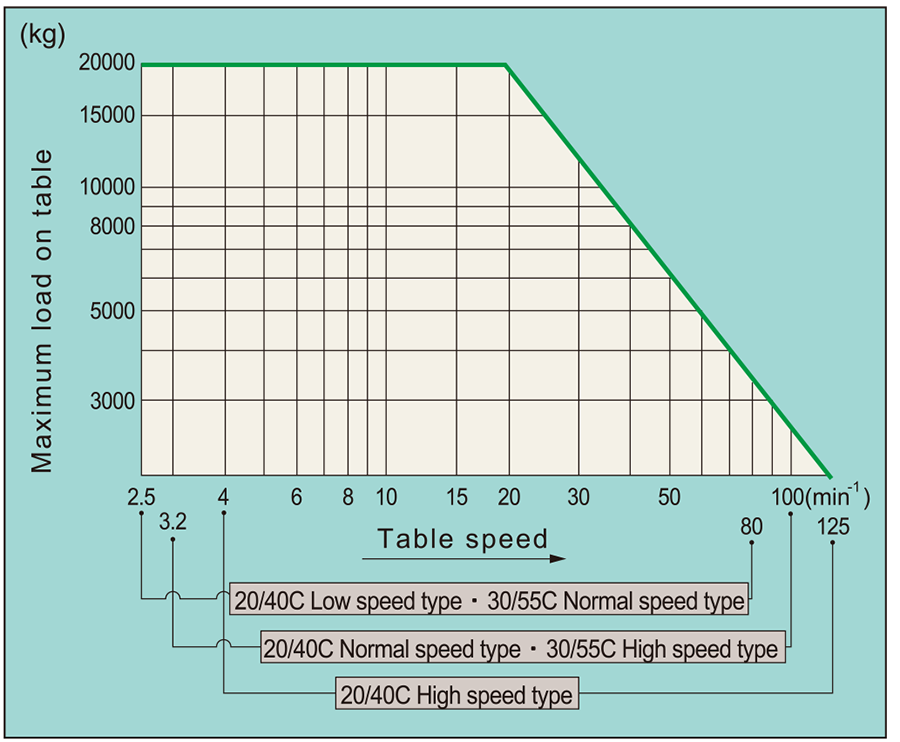

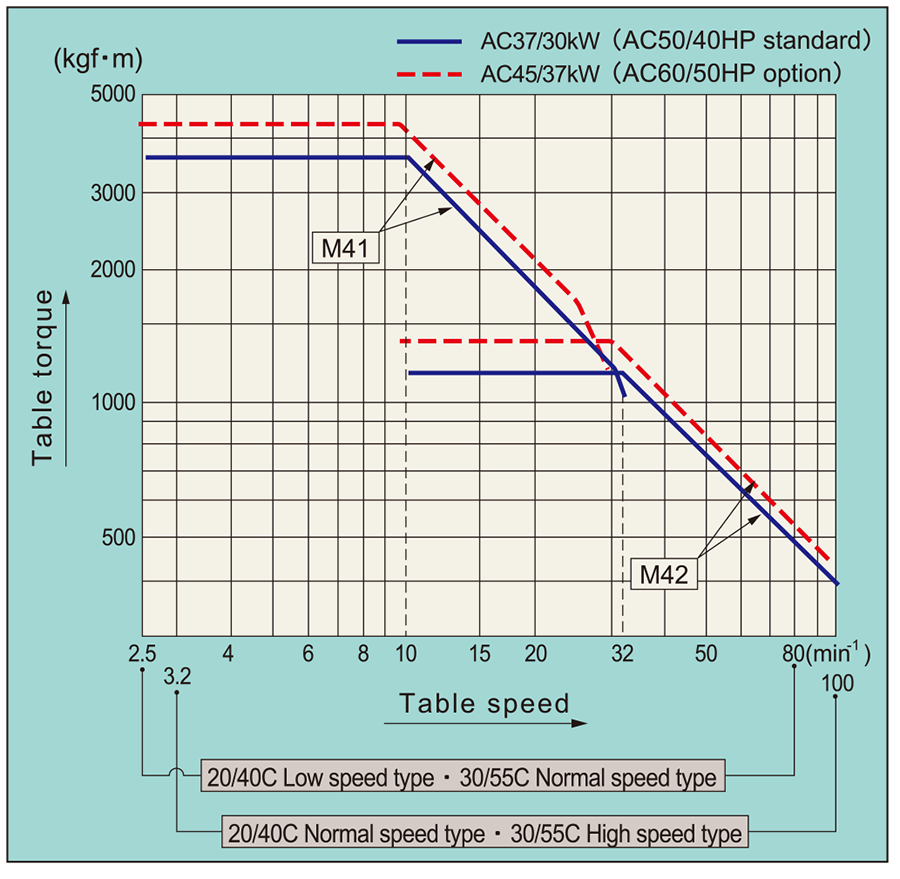

The table is suppoeted by a super-precision thrust cylindrical roller bearing and a tapered roller bearing, it maintains stable heavy-duty cutting operations at high speed even at machining of large-diameter helical gear under the table through a V belt and speed change gear train.Table speed change is performed by a two-range hydraulic shift and AC motor control.

The thick-walled, well-ribbed and box-shaped column has a wide sectional area to assure high rigidity and supports the arm by three guideways, The arm, integrated with the rear angle support, transmits cutting reaction force exerted on the rail head to the column with high efficiency.

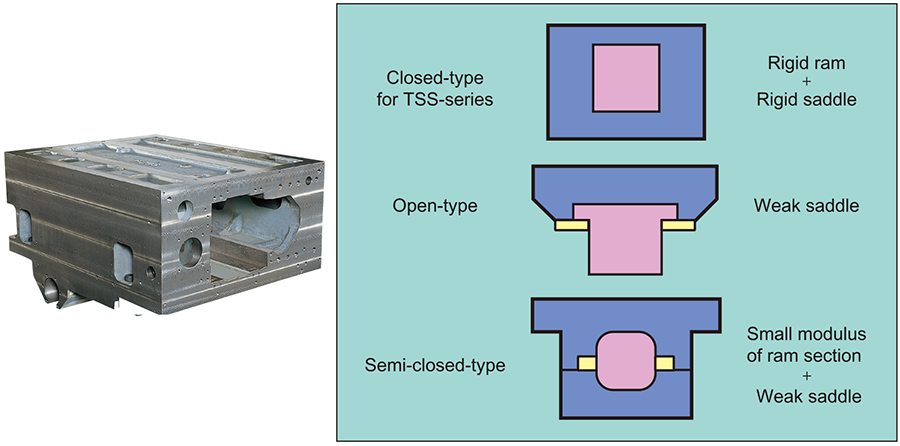

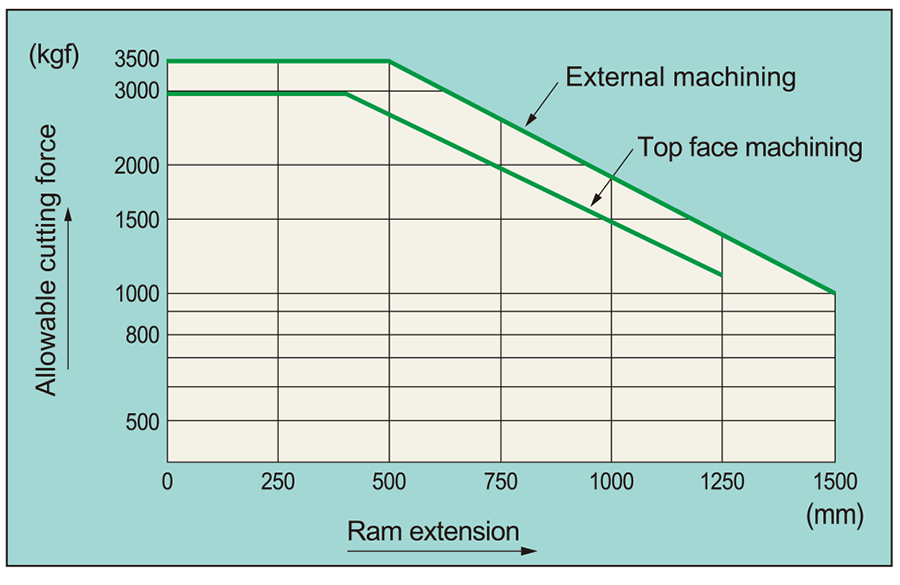

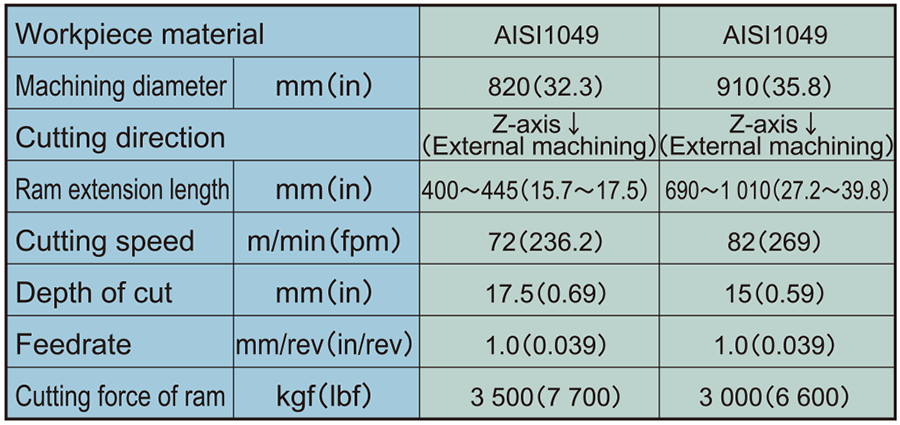

The maximum cutting force of the ram is more than twice that of our conventional machines even when the ram is extended to its maximum stroke. The maximum output of live spindle is 18.5kW(25HP). The closed type single-block constructed rail head enclosing a 250mm(9.84in) square ram and other main machine components made of high-grade cast iron all assure high rigidity and quality machining.

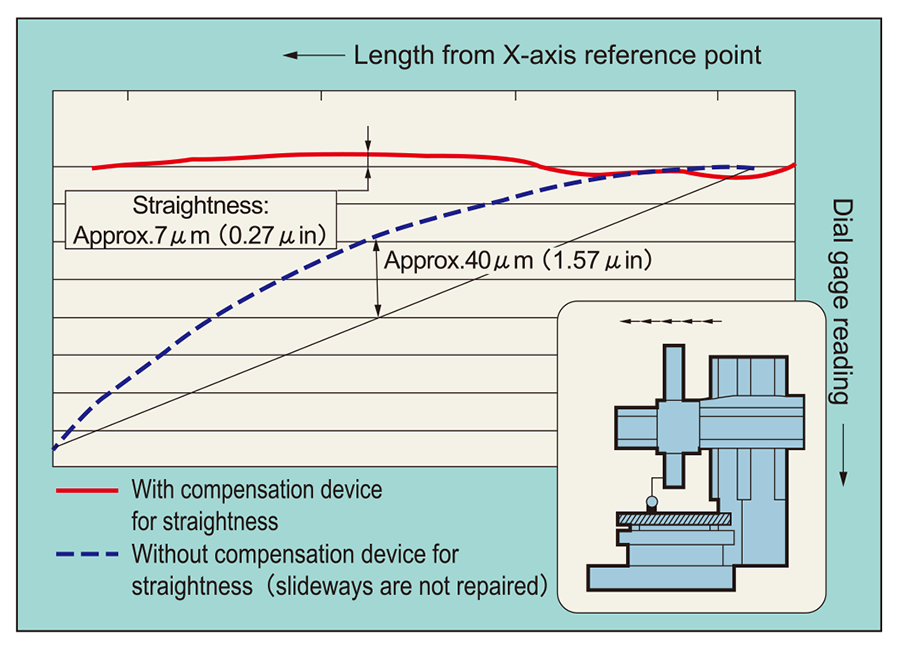

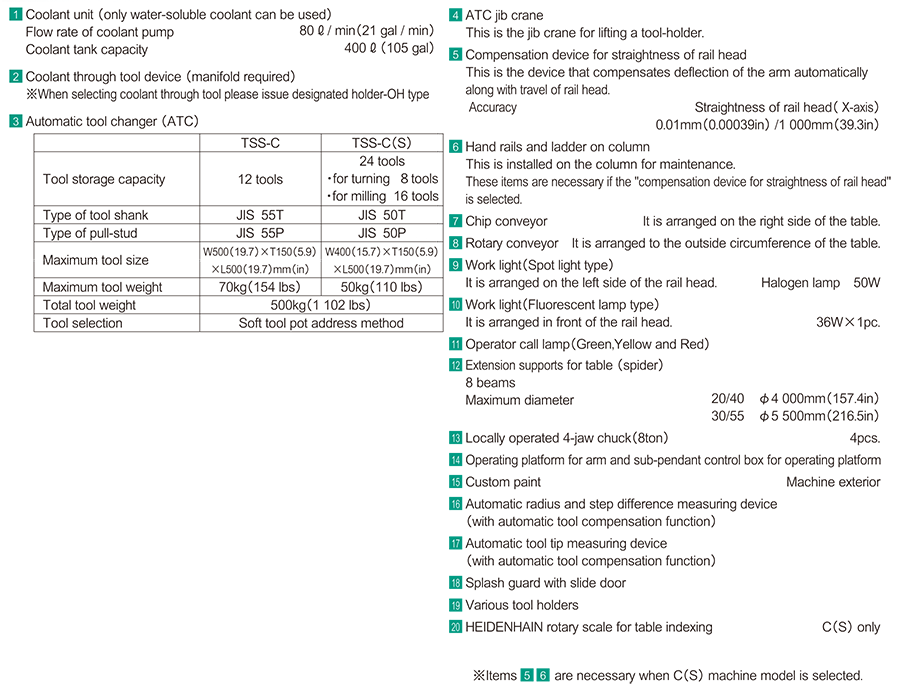

When incorporated in the machine, the compensation device for straightness of rail head travel(option) autommatically compensates arm deflection according to the rail head movement, Thus, more accurate working accuracies can be assured.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.