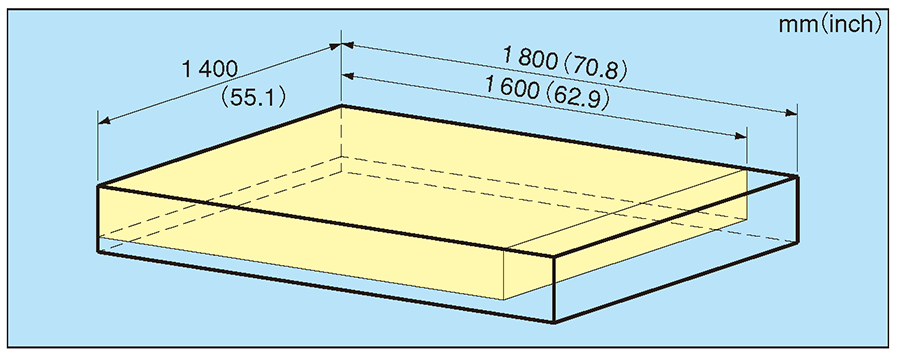

Efficient 6.1m by 6.1m (19.7ft by 19.7ft) “Square floor space”

High-level side discharge hinge-type chip conveyor.

Operator protection from chip and coolant with easy access

Ease of operation with manual pendant box and environmental platform

Enhanced functions and options from TOSNUC 999

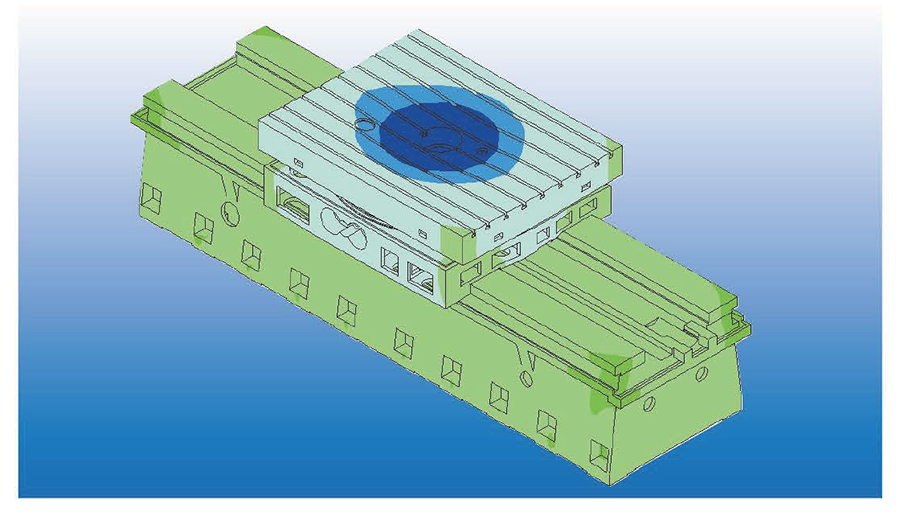

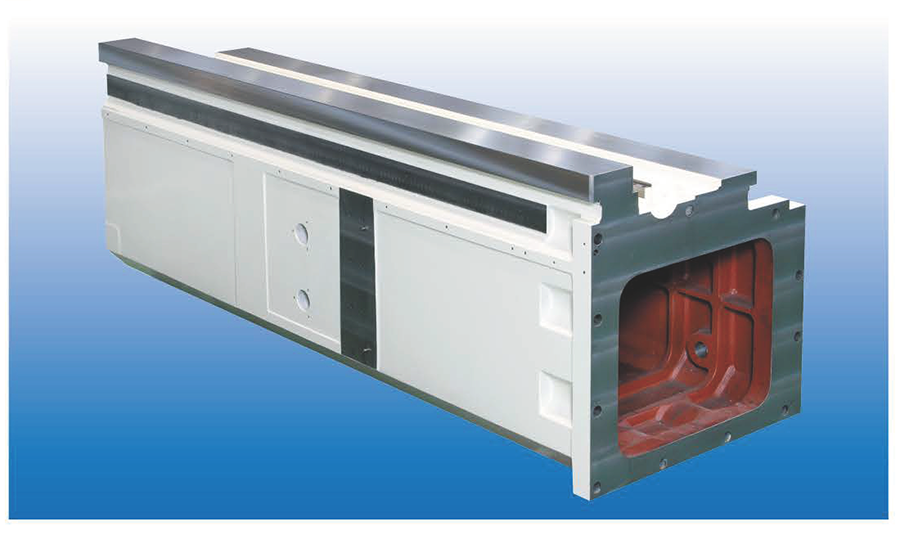

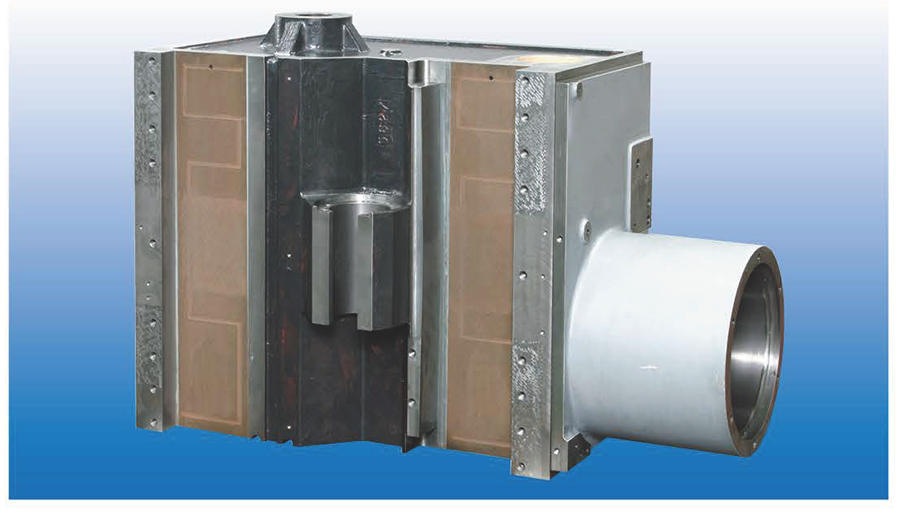

Solid and rigid cast iron table, bed and column structures

Accuracy of feed mechanism with minimal backlash

18m/min rapid speed is now available on Box-way guide High power spindle motor with 4000min-1 spindle speed

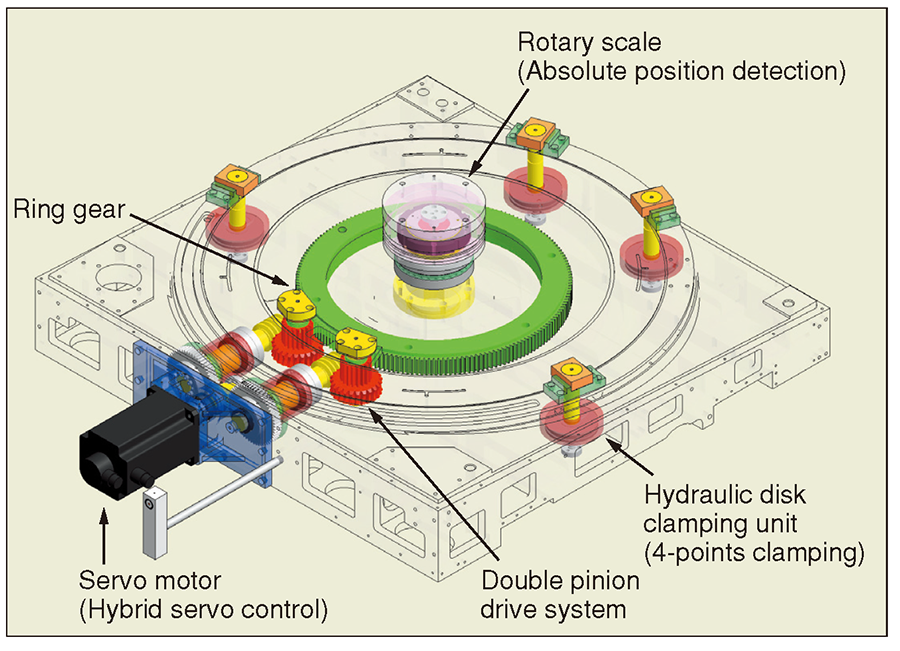

Expanded area of B axis slideway which takes heavy loads (1.4 times area of conventional machines), and increased thickness of the area.

B-axis positioning time : 15sec (0°~90°)

The revolutionary type of clamp is standard with a highly rigid double pinion-type drive system and rotary scale for stabilized precision table indexing.

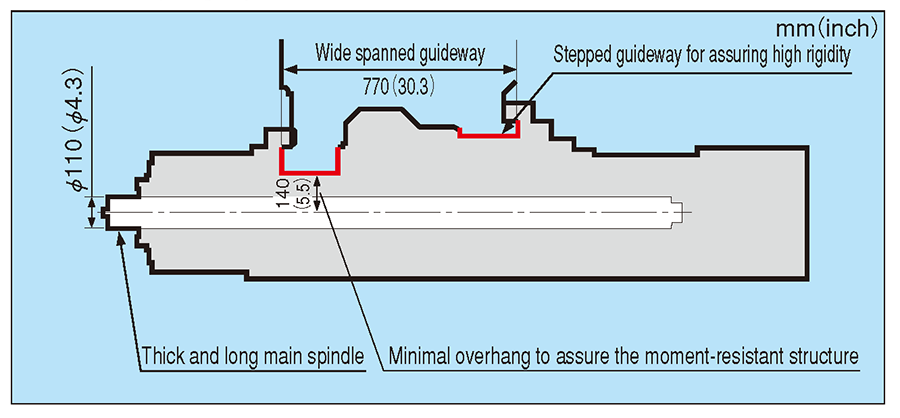

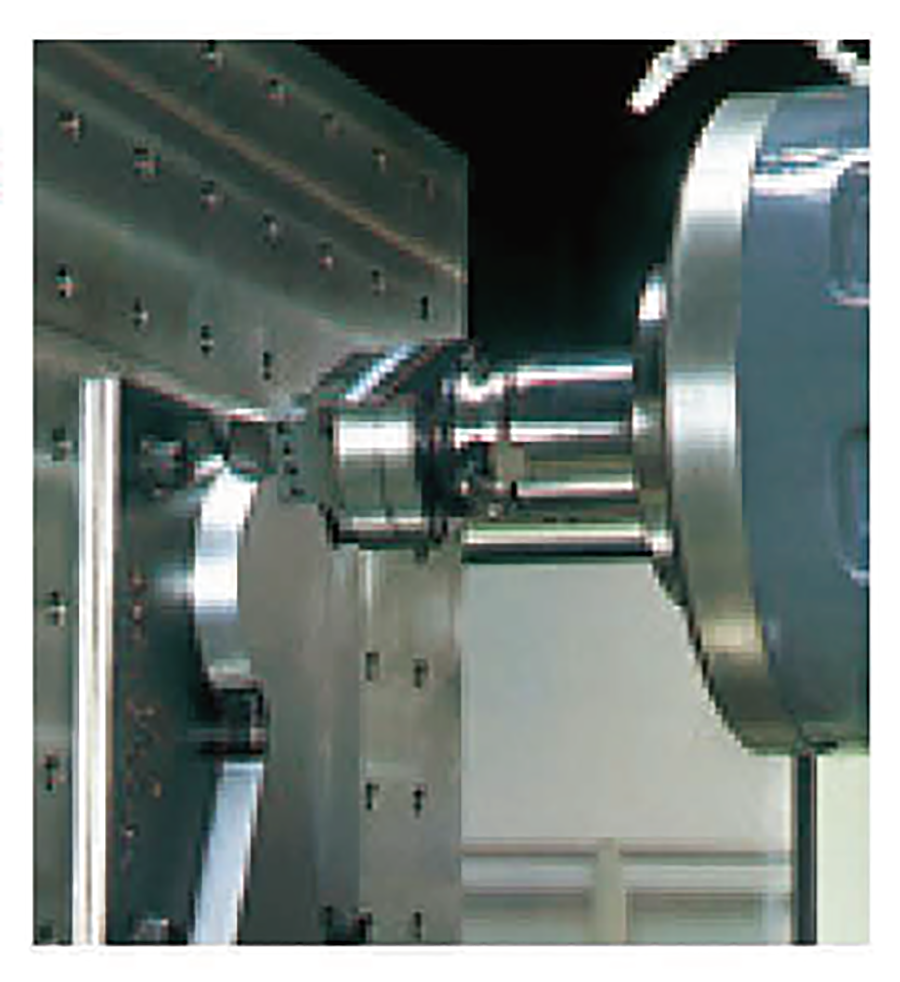

Extra wide spanned guideways that withstand heavy-duty cutting forces, thus improving the overall performance.

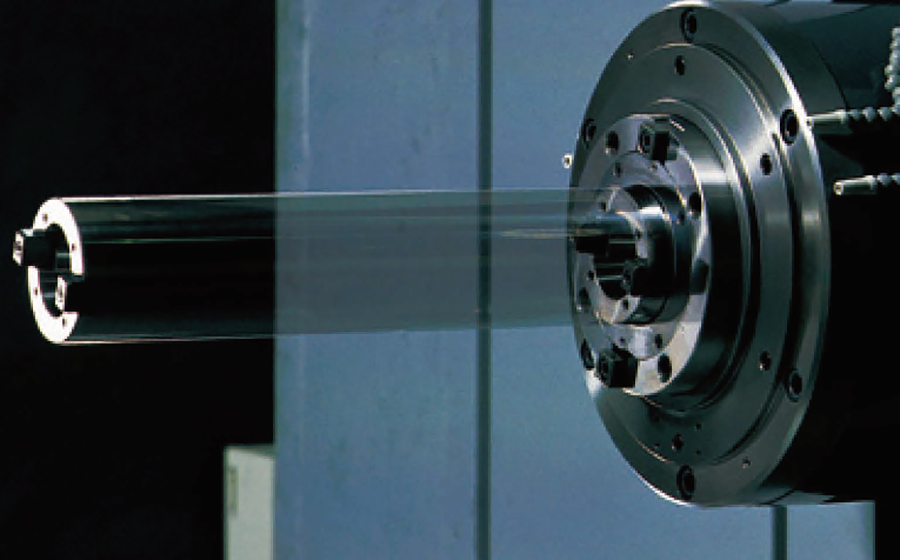

Main spindle completely nitrided, hardened and ground for maintaining highly accurate condition over the life of the machine.

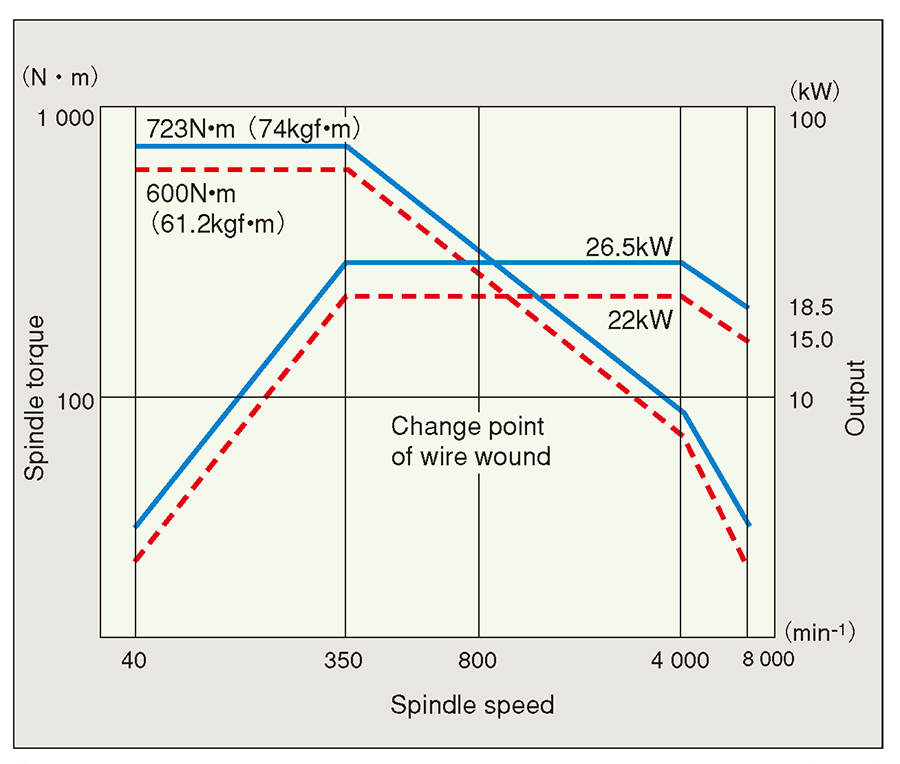

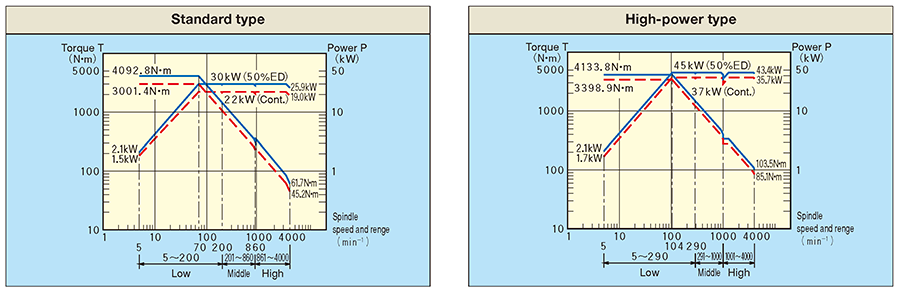

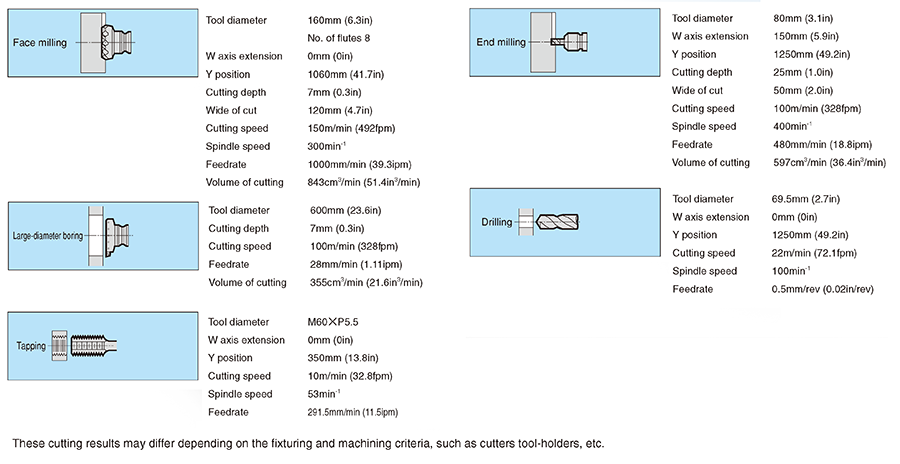

The gear transmission and the winding switching control type spindle motor adapted for the main-spindle drive system realize the wide speed range, high rigidity and high torque performance. BTH-110.R18 complies with various machining needs for horizontal boring & milling machine, such as milling, boring, drilling, tapping, etc., wherefore highly accurate and efficient machining can be performed.

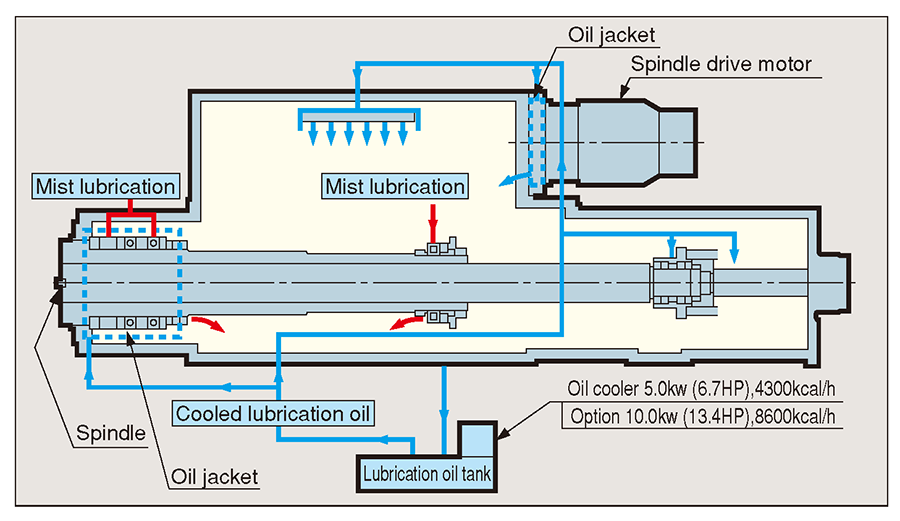

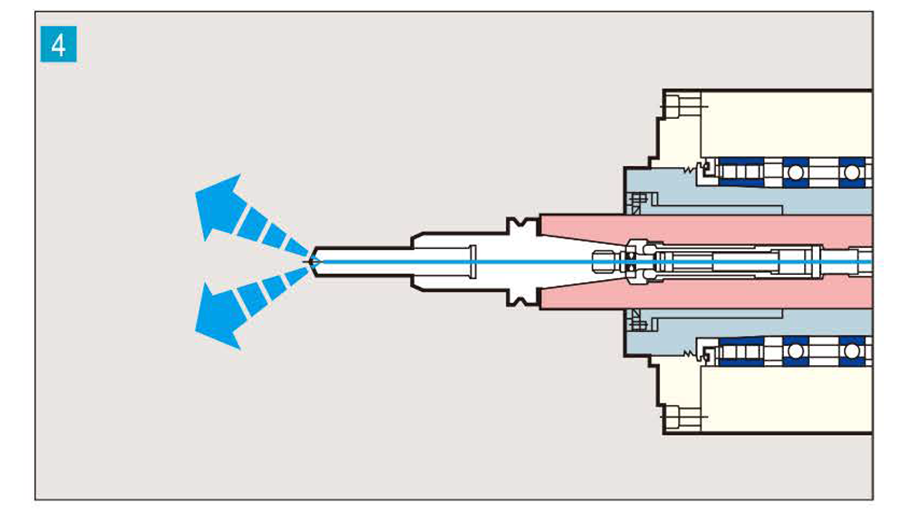

Use of an oil jacket and constant lubrication air mist volume for stabilized high accuracy cutting operations.

・Spindle bearings constant mist lubrication

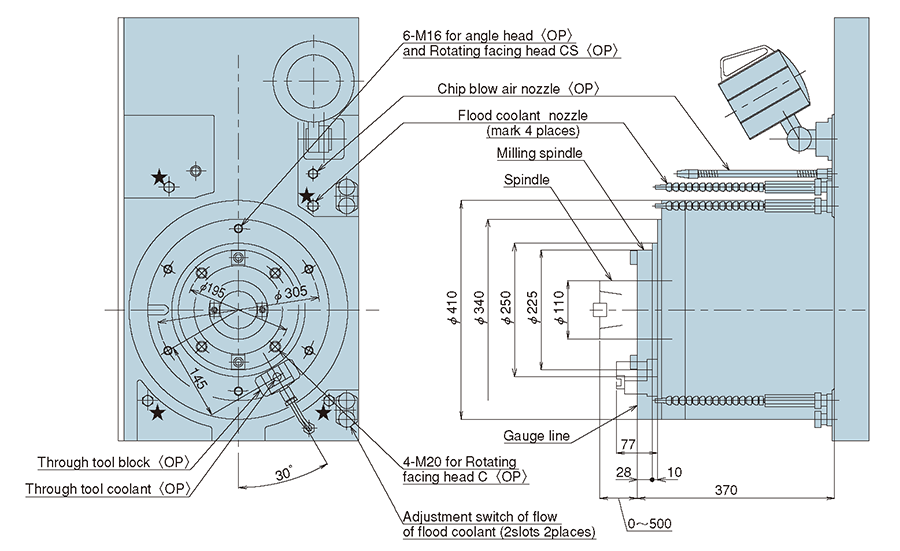

Composite machining of any shape such as cutoff and hale type finishing on an arc or along a straight line on any plane is possible with this C axis spindle control. Simpletype programs and tooling available for the machining of complex seal surfaces on the slots of such workpieces as vacuum devices.

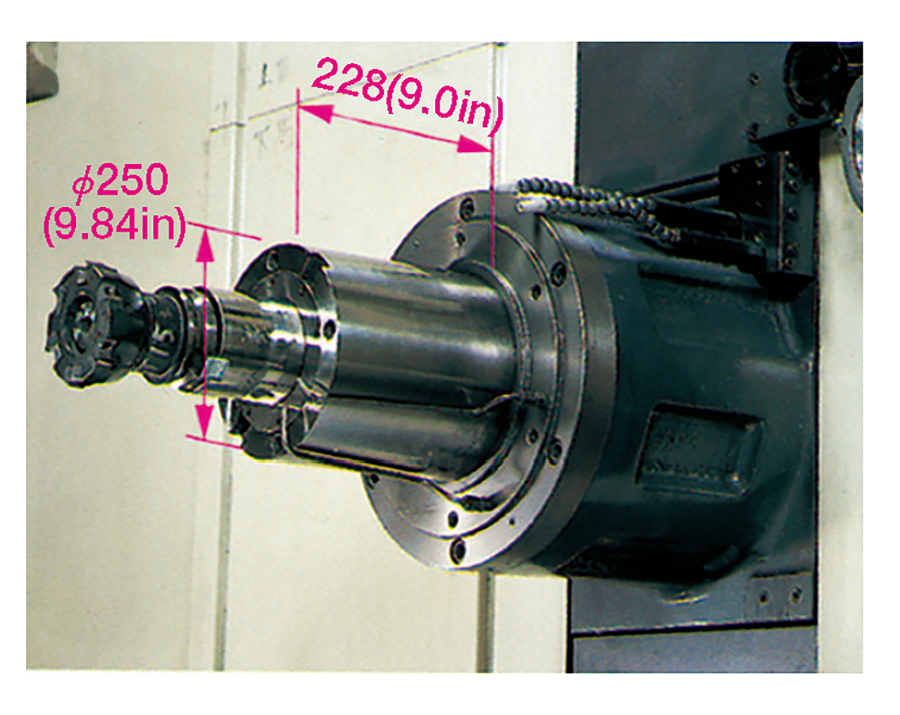

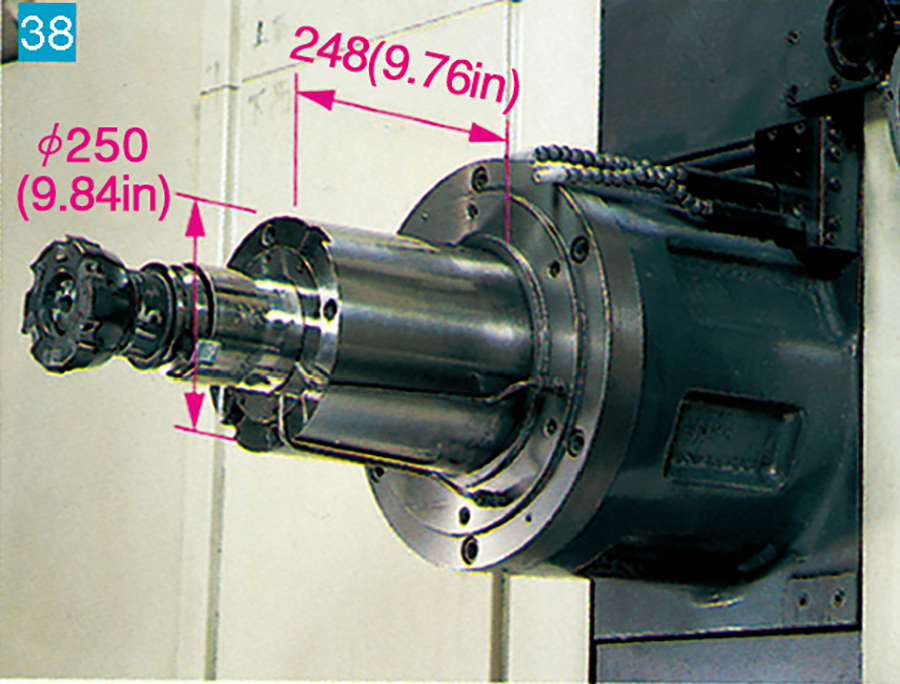

A long spindle head nose allows easy access to the workpiece, assuring stabilized accuracy even during heavy-duty machining operations.

(The spindle extension is 500 mm (19.7 in) same as standard.)

Note : Detailed of option specifications to be decided at a separate meeting.

※Capable of a variety of machining ranging from the rough cutting of steel alloys to precision machining of aluminum

A long spindle head nose allows easy access to the workpiece, assuring stabilized accuracy even during heavy-duty machining operations.

(The spindle extension is 500 mm (19.7 in) same as standard.)

Note : Detailed of option specifications to be decided at a separate meeting.

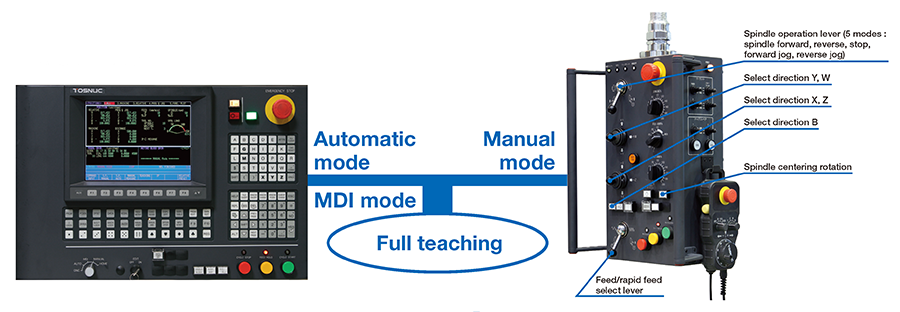

TOSNUC999 (Triple nine) permits quick switching between manual, MDI and Automatic operation modes.

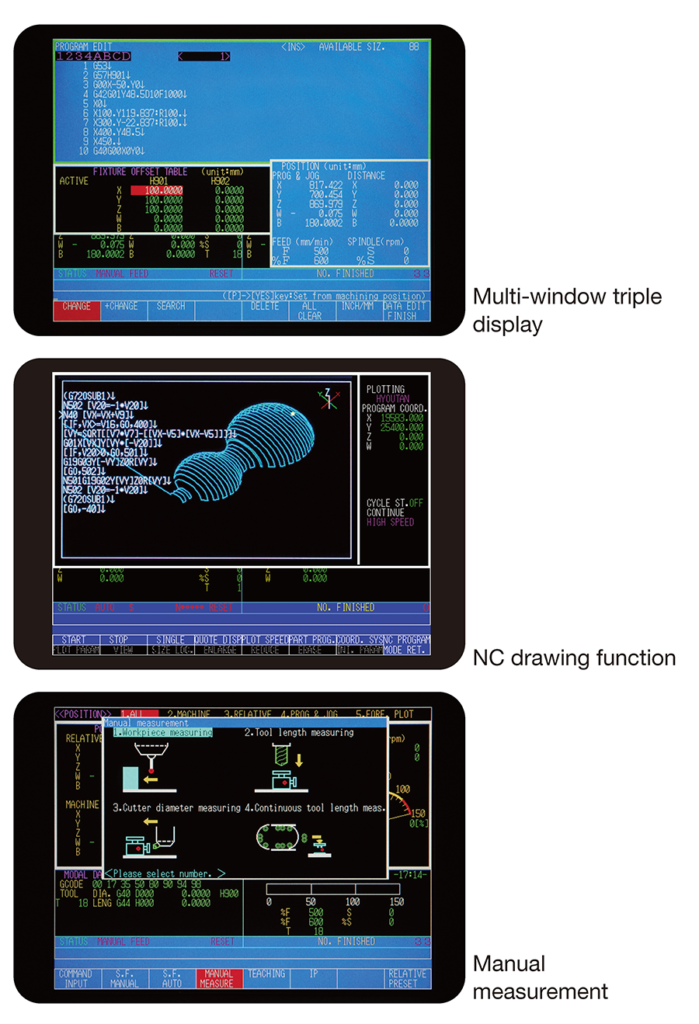

1.Memorize a series of input operations beforehand in one of the special keys and press these keys to execute operations continuously.

2.Memorize a combination of NC standard displays such as main, sub and window displays in one of the special keys . By pressing these keys it displays the combination memorized.

TOSNUC 999 is standard equipped with USB port and CF card slot in response to capacity enlargement of NC programs.

During programmed operation (i.e., background operation), an NC tape image of another program can be checked graphically. After program check, relevant tool path is drawn.

TOSNUC 999 stores in its memory all data created by the operator as NC programs. Programming is very easy by combining these programs, using various teaching functions.

Very useful device for managing long programs.

Manual operations relating to machine movements are separated from the NC operation unit and centrally arranged on the pendant operation box. Thus, combined NC and manual machining operations can be performed smoothly.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.