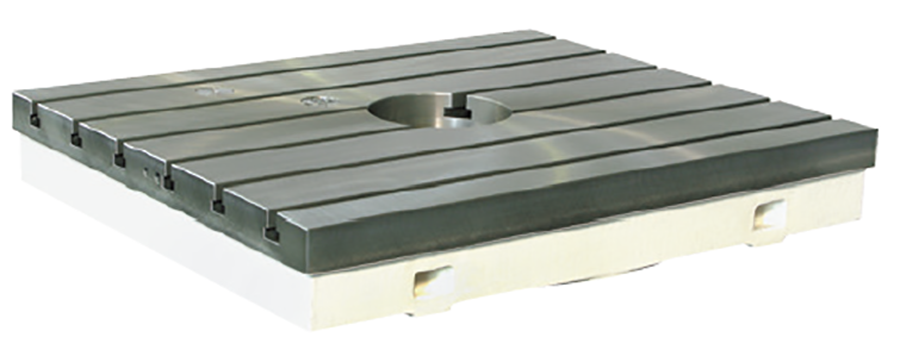

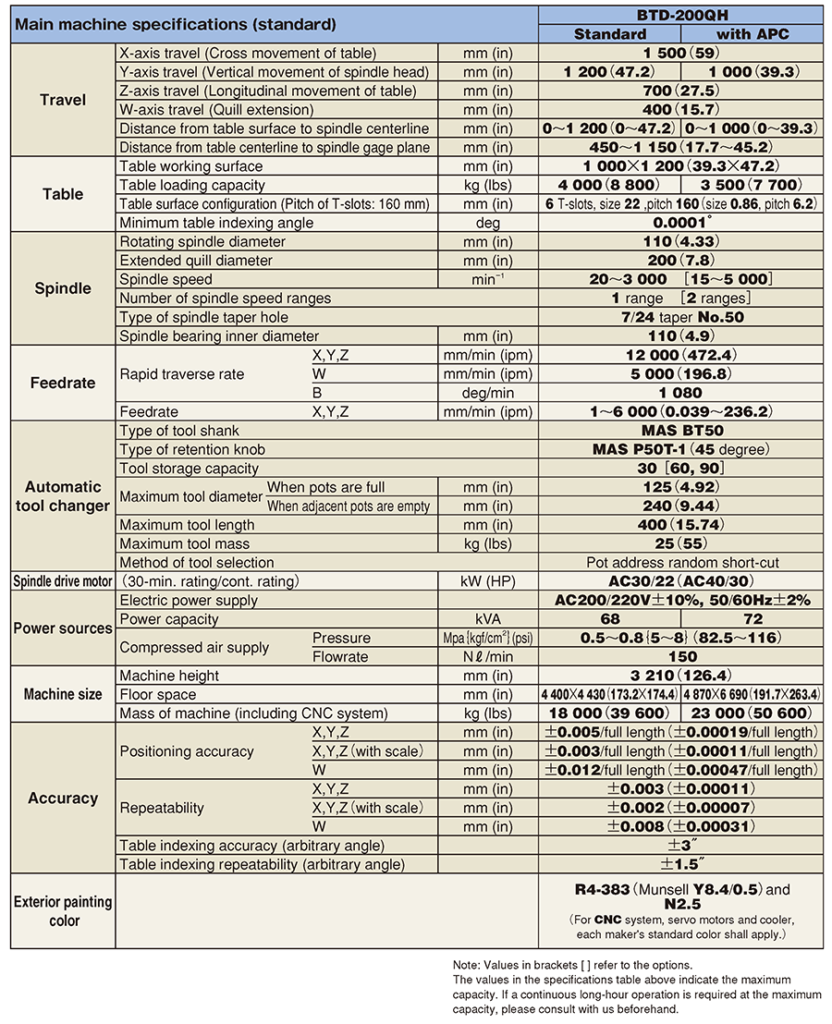

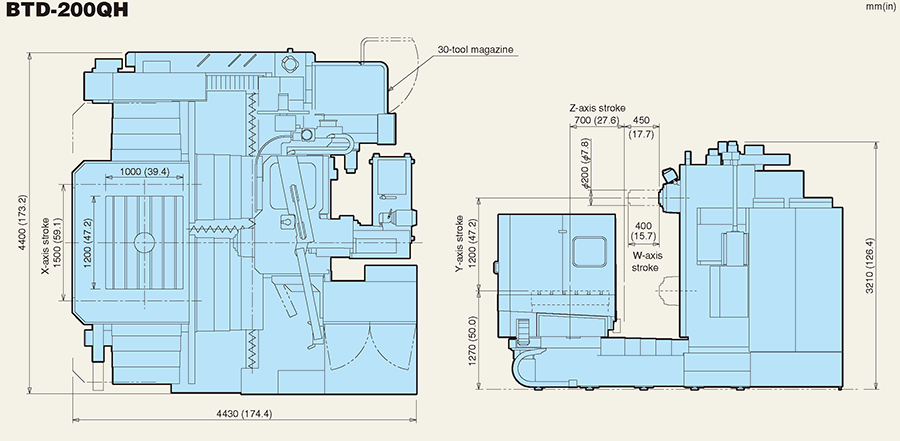

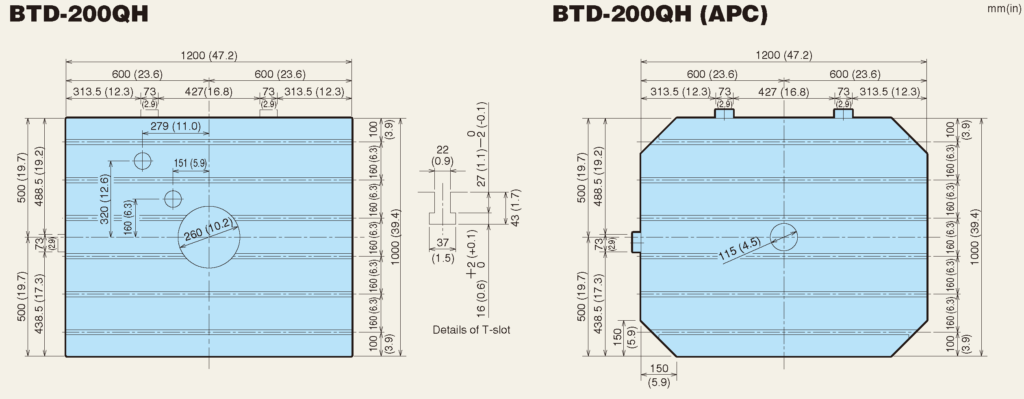

The table as wide as 1000 x 1200mm has a standard maximum load mass of 4 tons. Thus, enabling the set-up of work-pieces with longer widths.

The table as wide as 1000 x 1200mm has a standard maximum load mass of 4 tons. Thus, enabling the set-up of work-pieces with longer widths.

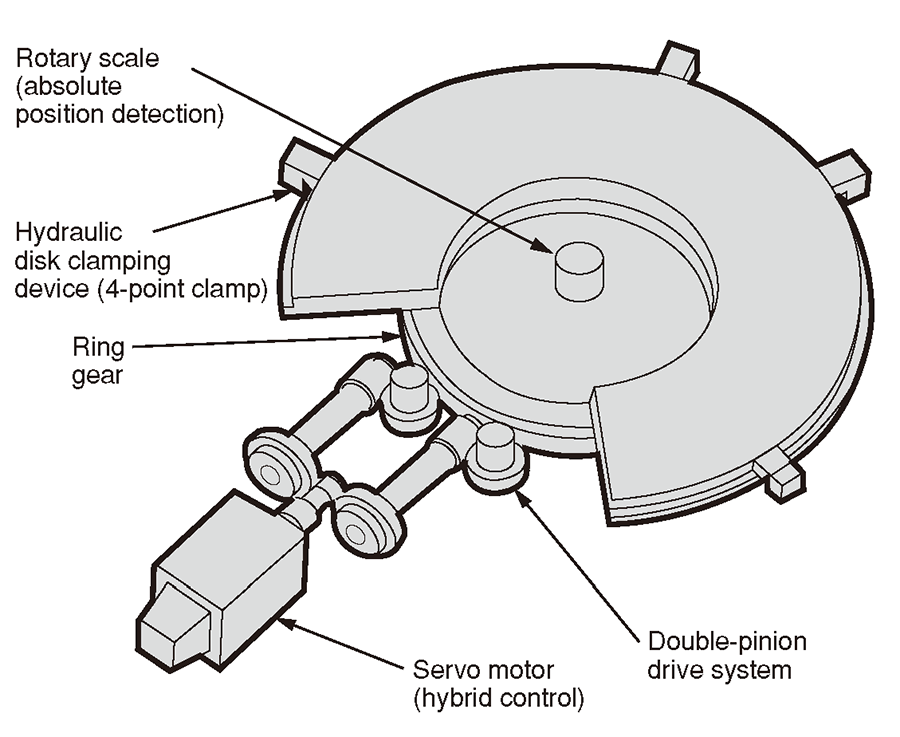

Use of the highly rigid double-pinion drive system and standard rotary scale emphasizes stable high-speed and high-accuracy table indexing operation

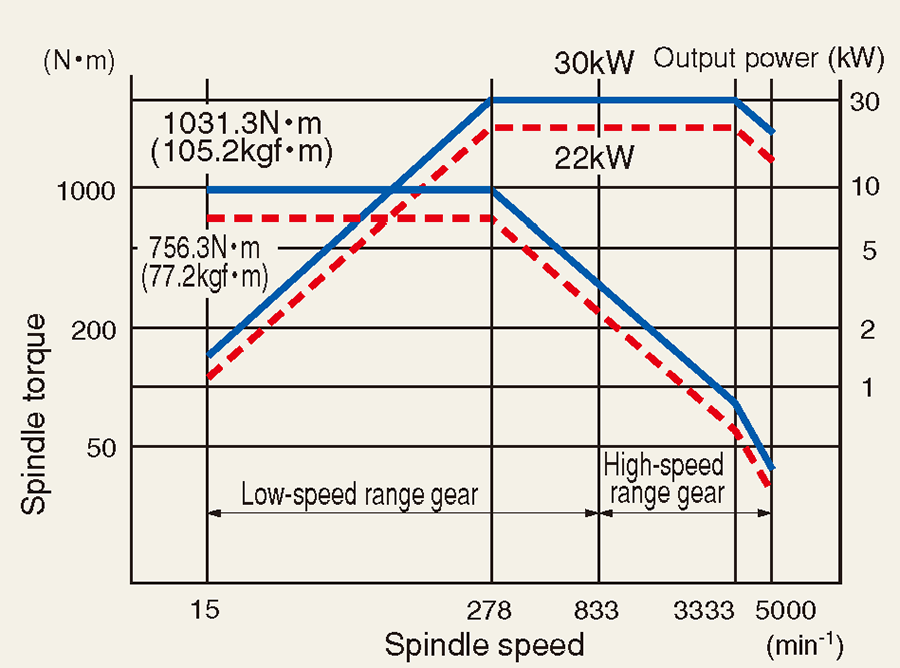

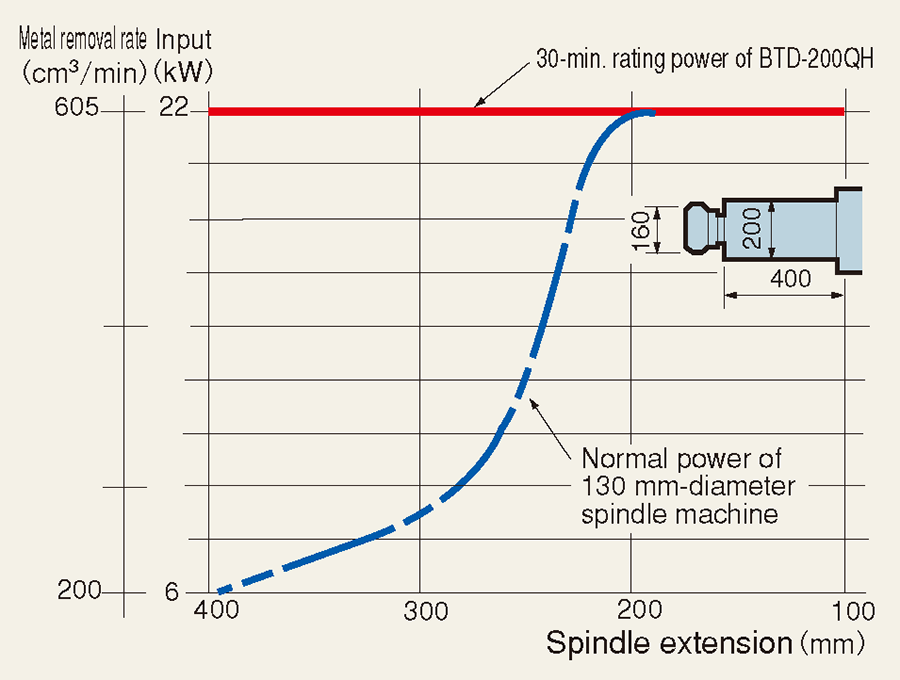

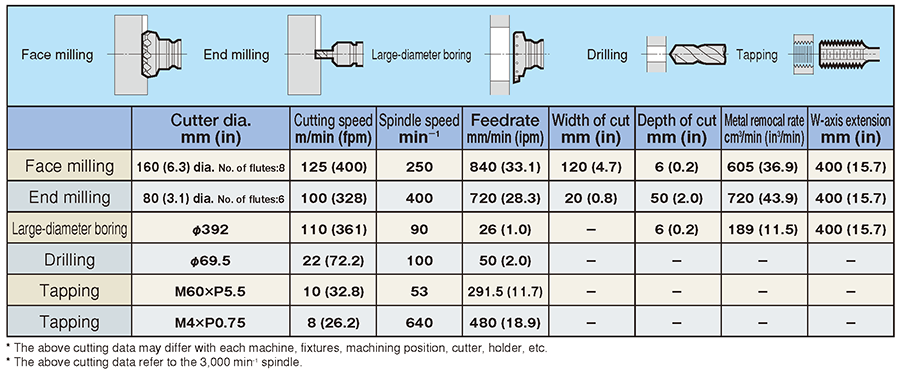

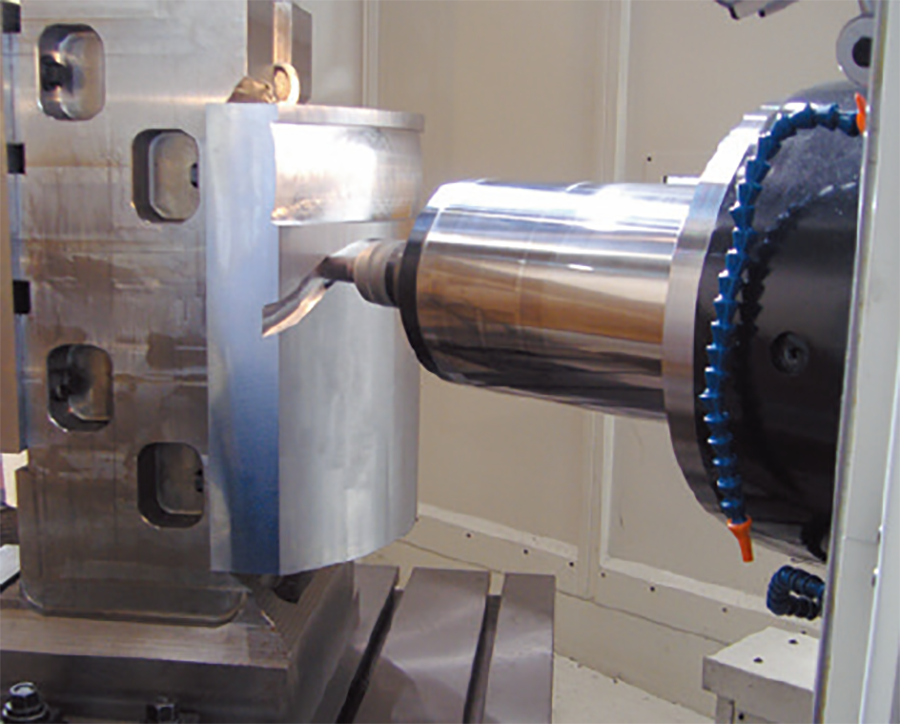

The mechanical two-stage gear change system with high-speed and high-torque 5000 min-1 spindle can cope with more extensive machining operations, exceeding the current high-rigidity quill structure

A cylindrical surface and end surface can be machined continuously by using the B-axis continuous indexing function of the table without using a special independent NC rotary table Easily

The table as wide as 1000 × 1200 mm has a standard maximum load mass of 4 tons. Thus, enabling the set-up of work-pieces with longer widths.

Use of the highly rigid double-pinion drive system and standard rotary scale emphasizes stable high-speed and high-accuracy table indexing operations.

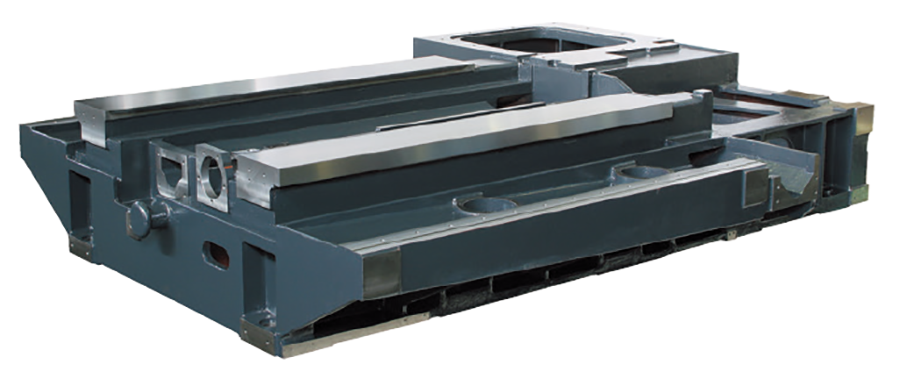

The new integrated type 4-way structure bed minimizes influences of load fluctuations caused by the movements of saddle and table, and maintains machining accuracy even at heavy-duty cutting operations.

A cylindrical surface and end surface can be machined continuously by using the B-axis continuous indexing function of the table without using a special independent NC rotary table. Easily create an NC program for the cylindrical surface using the cylindrical interpolation function (G67).

The mechanical two-stage gear change system with high-speed and high-torque 5000 min-1 spindle can cope with more extensive machining operations, exceeding the current high-rigidity quill structure.

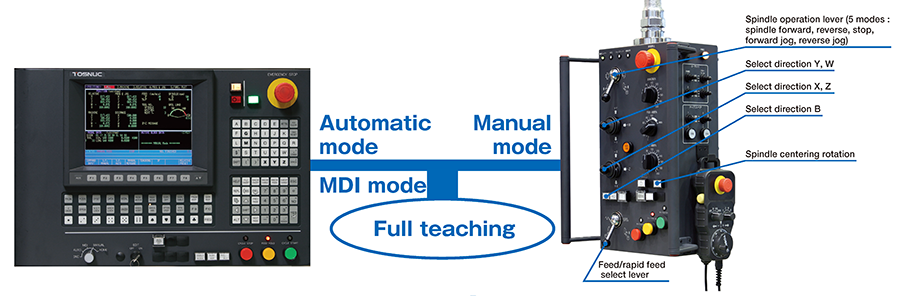

TOSNUC999 (Triple nine) permits quick switching between manual, MDI and Automatic operation modes.

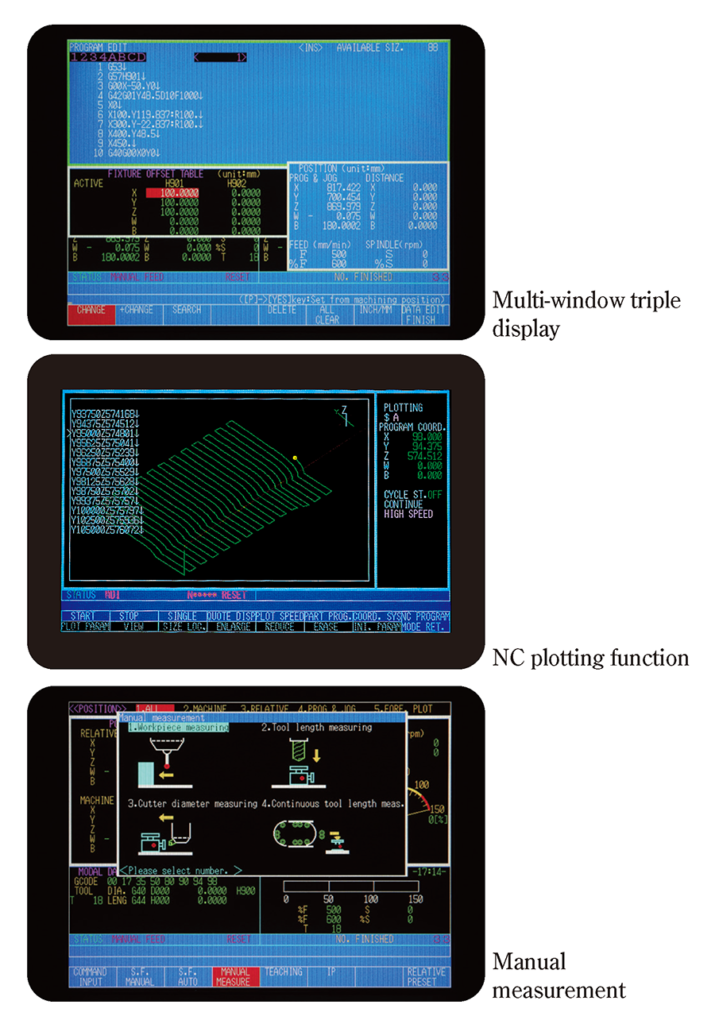

1.Memorize a series of input operations beforehand in one of the special keys and press these keys to execute operations continuously.

2.Memorize a combination of NC standard displays such as main, sub and window displays in one of the special keys. By pressing these keys it displays the combination memorized.

A compact flash (CF) slot is standard-equipped to cope with large-capacity NC programs.

During programmed operation (i.e., background operation), an NC tape image of another program can be checked graphically. After program check, relevant tool path is drawn.

TOSNUC 999 stores in its memory all data created by the operator as NC programs. Programming is very easy by combining these programs, using various teaching functions.

Very useful device for managing long programs.

Manual operations relating to machine movements are separated from the NC operation unit and centrally arranged on the pendant operation box. Thus, combined NC and manual machining operations can be performed smoothly.

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.