Sharp cut in air consumption.

Complete elimination of oil mist scattering into the air.

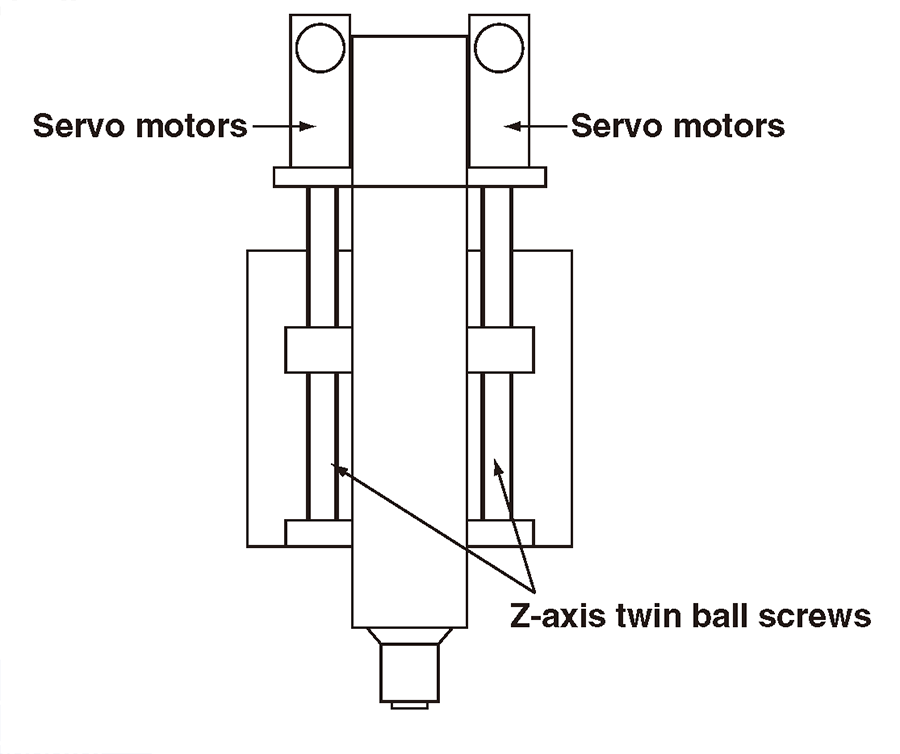

Energy-saving Z-axis twin ball screws, not requiring any balancing unit.

“Rapid traverse rate: 30m/min (X-, Y-axes)

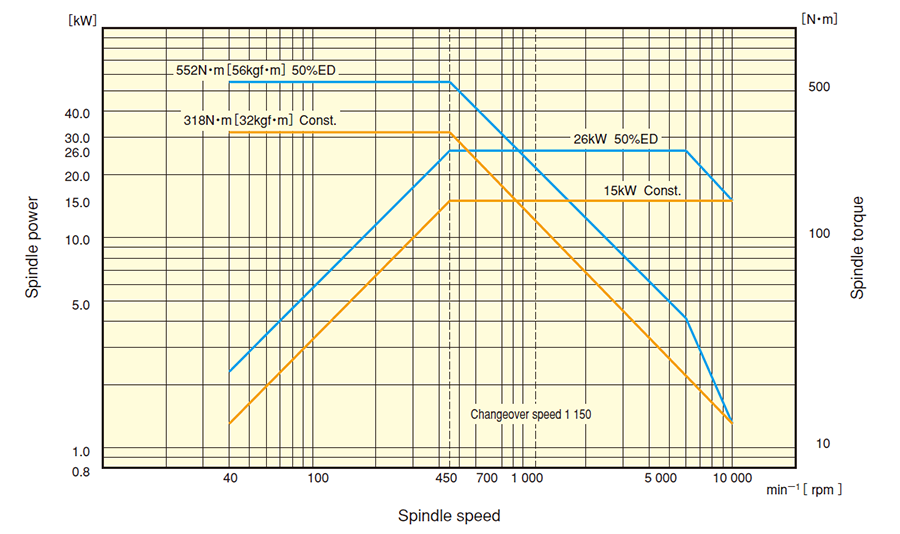

Spindle speed range: 40 – 10000min-1

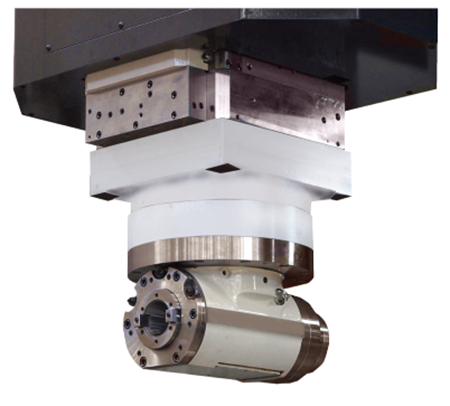

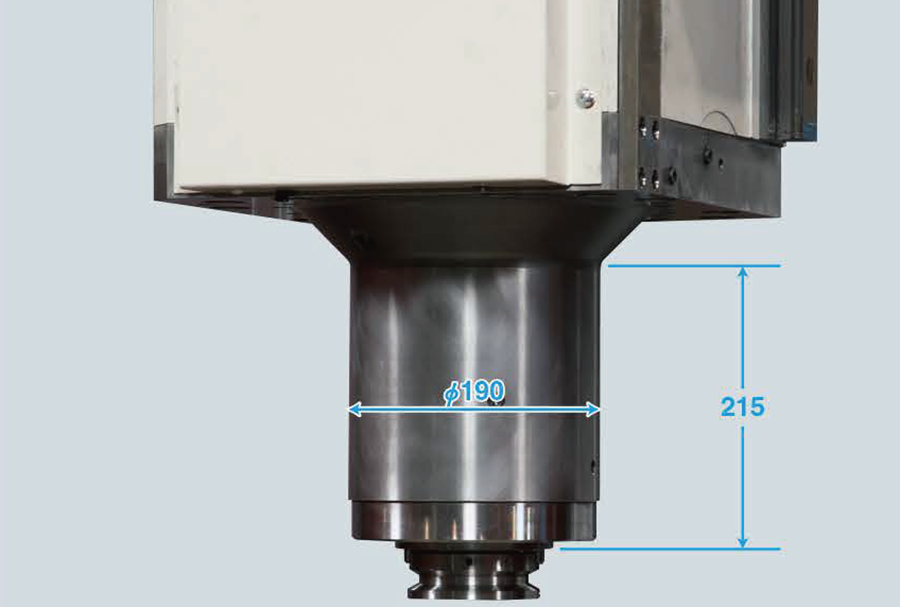

Cartridge spindle, considering easy maintenance

190mm-diameter long nose satisfying both easy access and heavy-duty cutting”

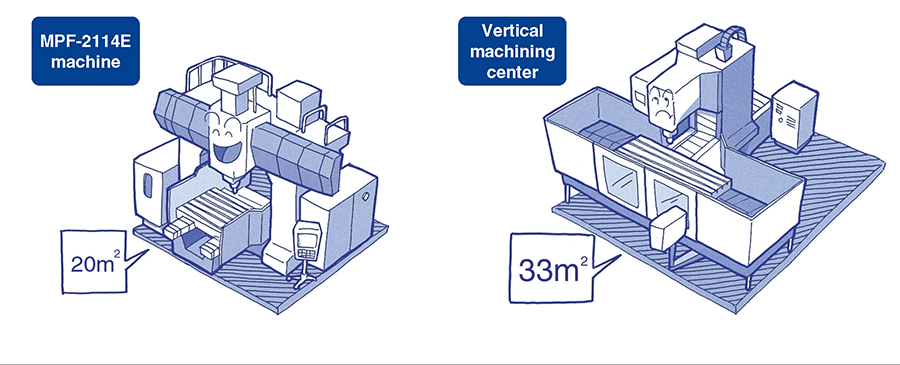

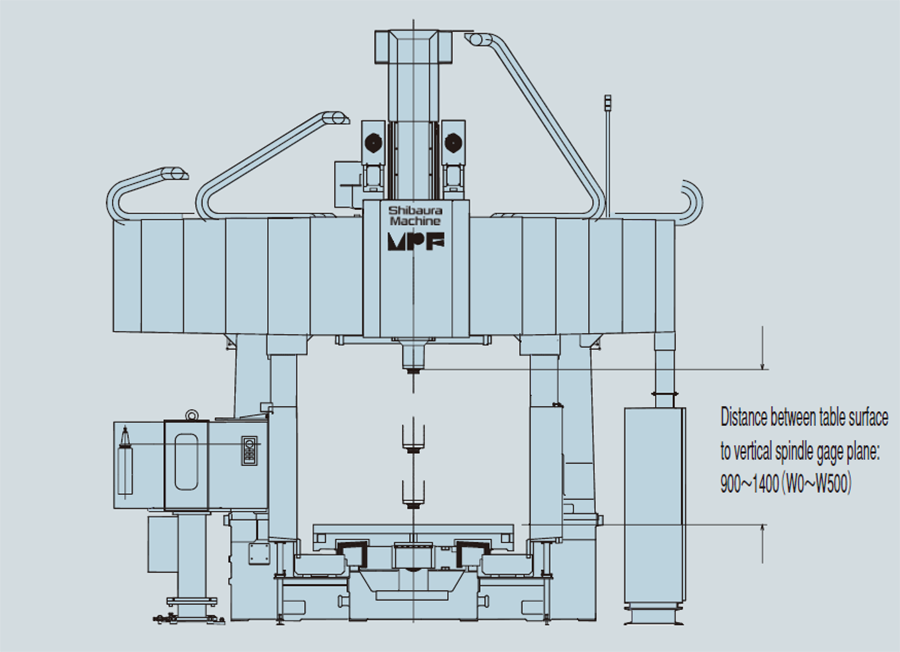

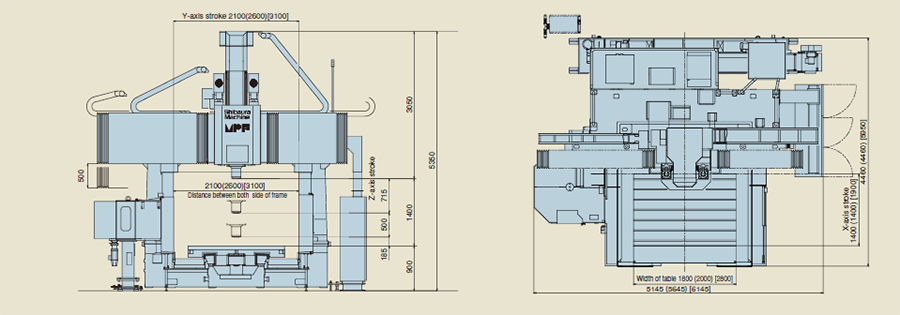

In spite of the machine whose distance between columns is 2100mm, the installation space is as small as 20m2, which is smaller than the vertical machining center having equivalent machining range.

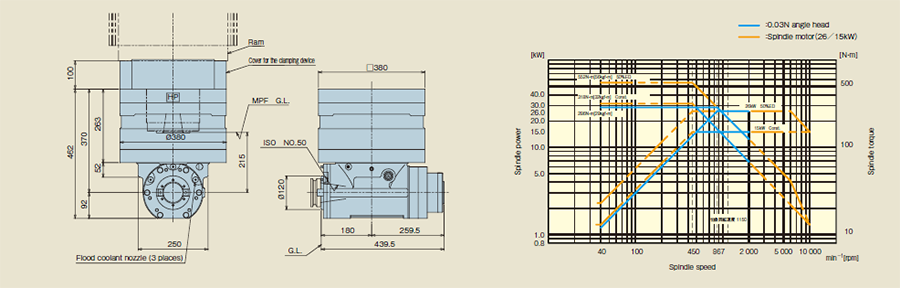

The optional angle head extend machining capability on the MPF series machine to five-side on a workpiece in order to increase machining efficiency on her.

The machine is able to work on four-side of workpiece with the optional angle head, in addition to work on top face with the standard snout, in single set-up.

Maximum power : 3kW at 100 min-1

Maximum torque : 286N・m(29kgf・m)

Maximum speed : 2000min-1

Tool change : AATC

(An optional special tool changer with AATC feature is required)

Allow AAI : at every 90 positions

Sharp cut in air consumption.

Complete elimination of oil mist scattering into the air.

Energy-saving Z-axis twin ball screws, not requiring any balancing unit.

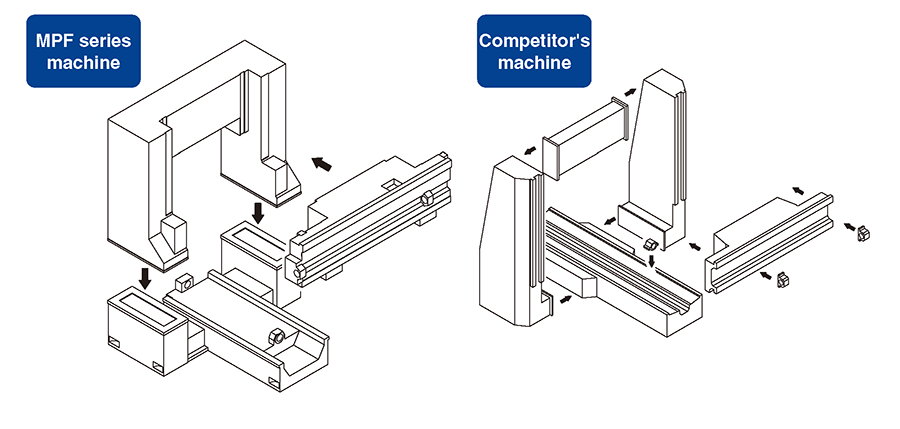

Rigid and stable movement in positioning is derived from crossrail configuration.

Crossrail, which travel on wall column, is supported by two rigid and stable saddles and has low gravity center to assure high accuracy and rigidity.

In spite of the machine whose distance between columns is 2,100 mm, the installation space is as small as 20 m2, which is smaller than the vertical machining center having equivalent machining range.

A basis for machine rigidity is provided by integrally cast columns and crossrail characterized by high rigidity.

The snout has long nose of 190 mm diameter to achieve high rigidity on the spindle and better accessibility to a workpiece.

The Z-axis is driven by the twin ball screws, which eliminates the need of any balancing unit. Energy-saving and quick response features are particularly effective in profile machining such as machining of dies and molds.

The Z-axis is driven by the twin ball screws, which eliminates the need of any balancing unit. Energy-saving and quick response features are particulaThe crossrail can be elevated 500 mm at 250 pitches at three positions by means of a hydraulic cylinder. Thus, the machining range is extended and machining is possible at the optimal extended position of ram.rly effective in profile machining such as machining of dies and molds.

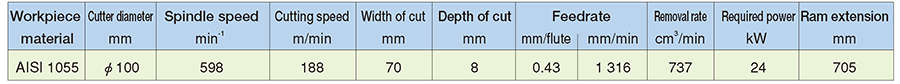

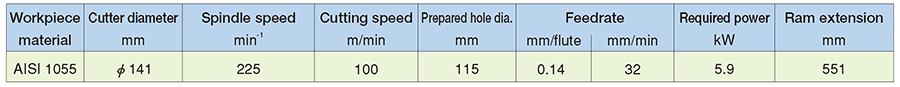

・Face milling

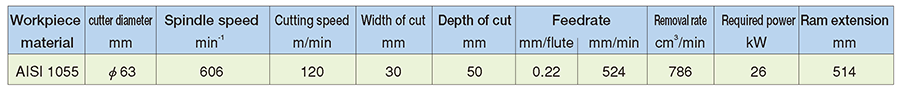

・End milling (side-face milling)

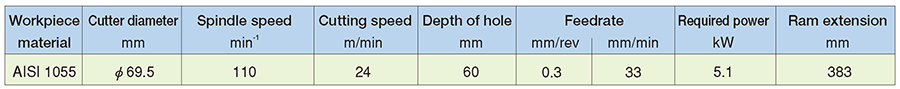

・Boring

・Drilling

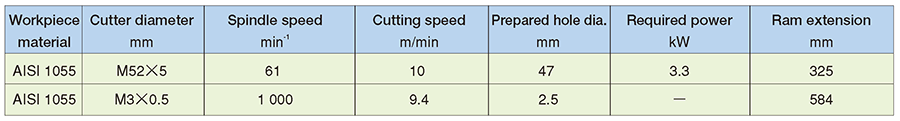

・Tapping

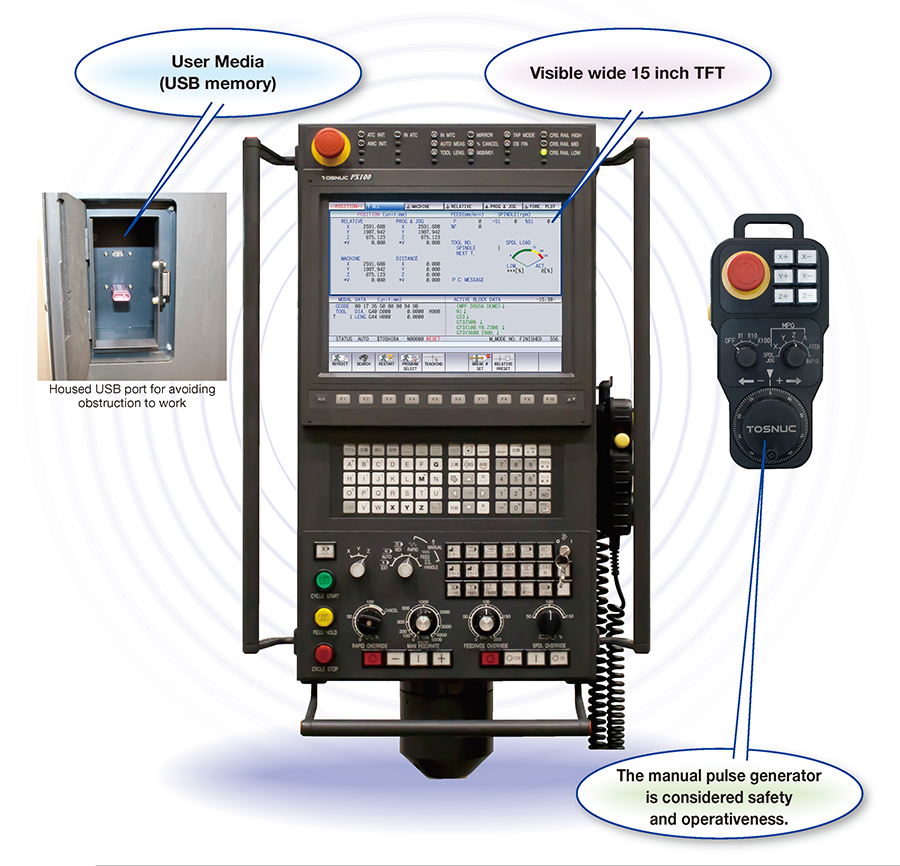

TOSNUC PX100, A personal computer architecture. Integrated into our TOSNUC controller developed

specifically to enhance our CNC controller with higher performance functions and even more versatility.

Our goal to create more innovative features that support easier operation thus contributing to an increase in productivity and machine performance.

Based on our extensive experience integration between mechanical and electronic technology. Our new CNC controller was developed with an emphasis on easy operation, easy to understand and easy to remember.

This perfect combination is the Key to achieving higher machining accuracy in high speed machining.

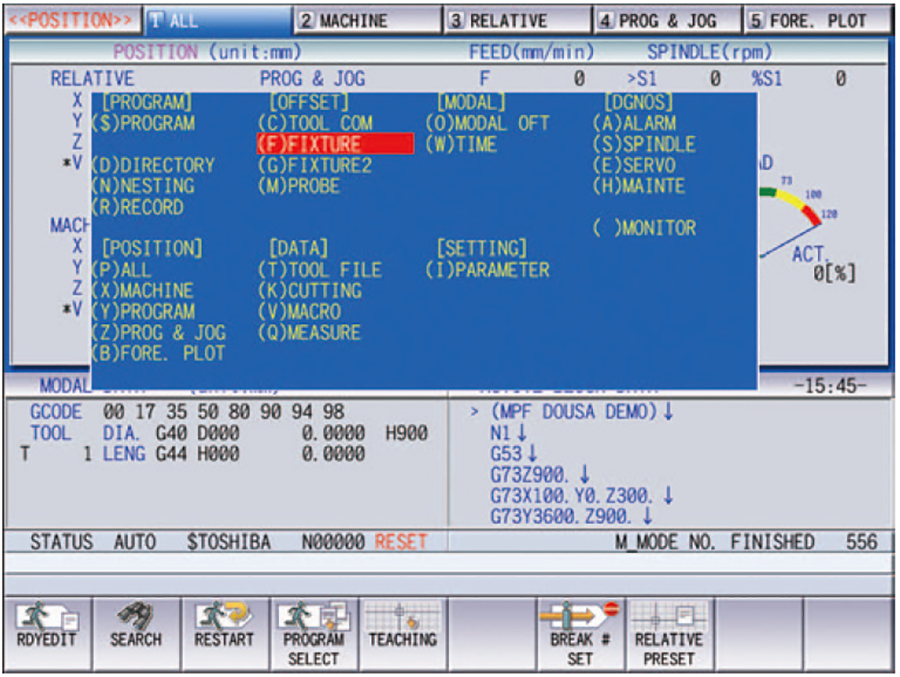

By pressing a soft key on the selected screen a menu will appear showing the desired function on a sub display window.

Having a pop up display menu type system avoids complicated hierarchy in software and shortening the scan time to process a desired function.

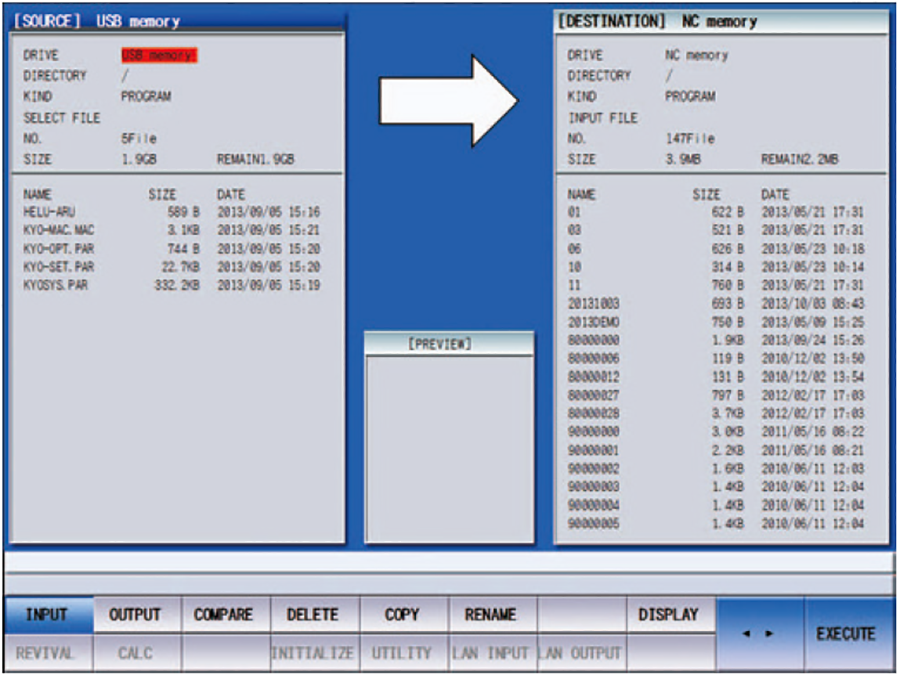

Multi-task and multi-window is a feature that enables you to open a window file from any current screen to perform program input/output deleting or copy a program to execute a calculator screen clipboard.

Program list and memory are connected to a user media and displayed on the screen allowing the program to be checked in a preview window within the same screen during input or output of programs from a user media.

The screen can be divided into three sections to display two program screens and the third shown MODAL OFFSET DATA compensation information which is required upon machining.

These three screens run independently during automatic operation and during editing.

A new program can be generated and created utilizing a clipboard feature and or background split screen edit two programs simultaneously as compared to a personal computer.

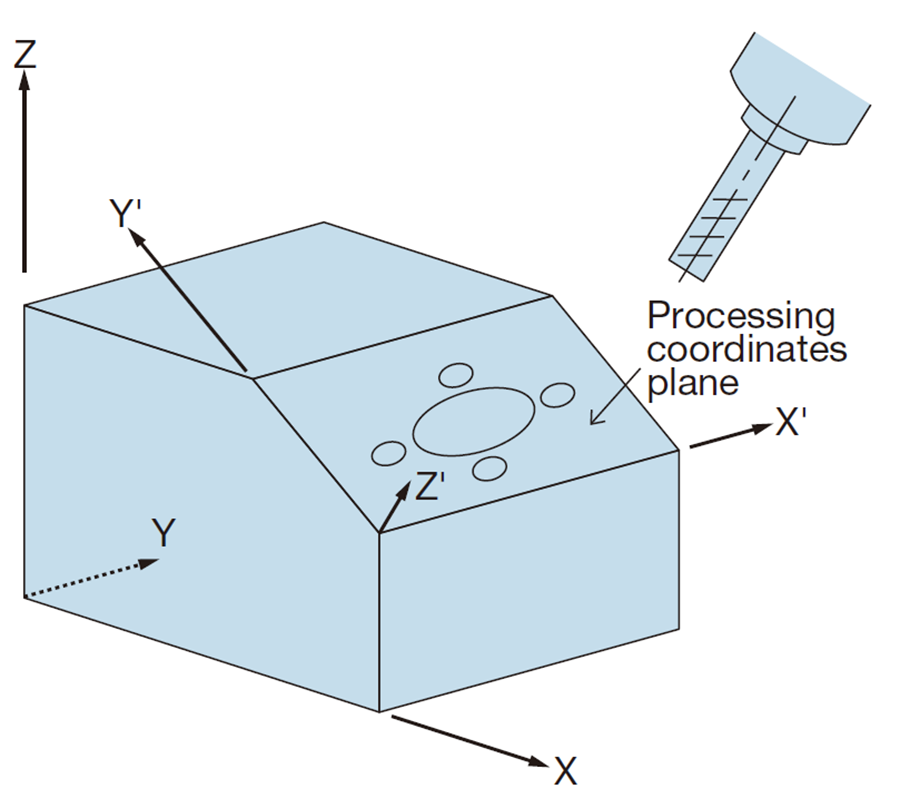

A general program running on G17 plane when programmed on X-Y plane and machining a depth on inclined surface as shown does not require a program modification. This very important feature convenient and executable with G command and canned cycle simplify machining of an inclined surface without effort.

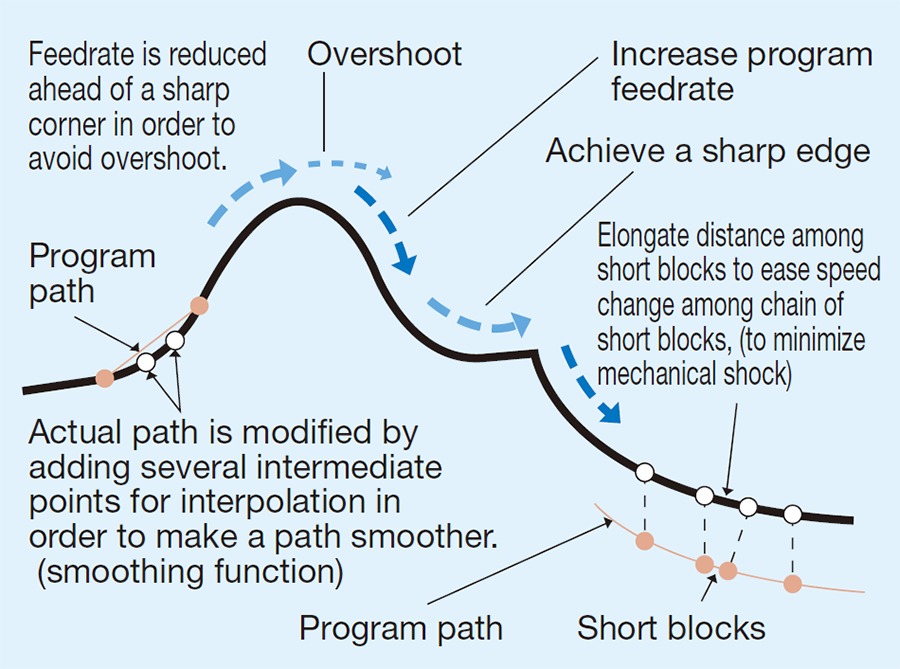

Generally, a profile to be machined requires a true shape and shape error decrease as servo gain increase. However high gain causes over shoot and increases machine vibration from large acceleration to mechanical system, which causes a bad surface finish in machining.

Preview control based on optimum control theory is developed to prevent such affect on machined surface and minimize shape error without setting high gain.

(In the case of MPF-3116FS with 200 mm length tool)

(Items marked ☆ are included in the pack specifications.)

(Items marked ☆ are included in the pack specifications.)

(Items marked ☆ are pack A specifications, which are included in the standard specifications.)

Copyright © 2020 SHIBAURA MACHINE CO.,LTD, all rights reserved.